Indicating light optical state automatic test method and system

An automatic test system and optical state technology, applied in the direction of testing optical performance, etc., can solve the problems such as the inability to accurately reflect the optical state of the indicator light, the inability to accurately obtain the flashing frequency of the indicator light, and increase the complexity of the hardware design, so as to achieve automatic testing. And the effect of evaluating, reducing test complexity, and complete test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

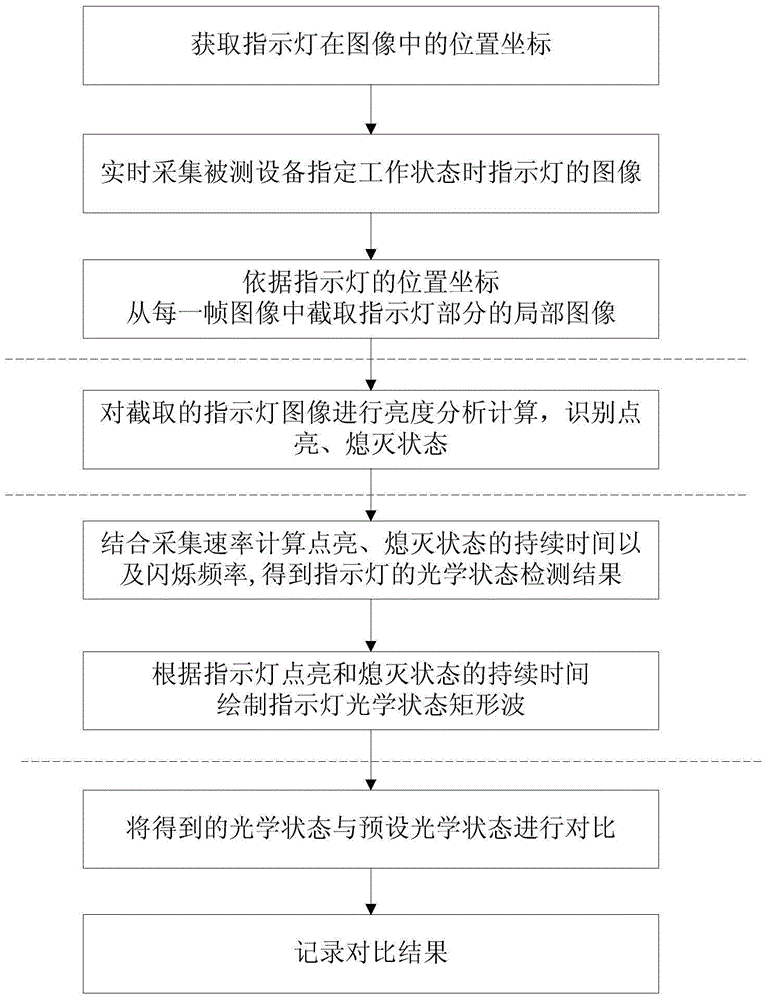

[0046] Such as figure 1 As shown, the automatic test method for the optical state of the indicator light in this embodiment, the steps include:

[0047] 1) Image acquisition: real-time acquisition of the image of the target indicator light when the device under test is in a specified working state at a preset acquisition rate;

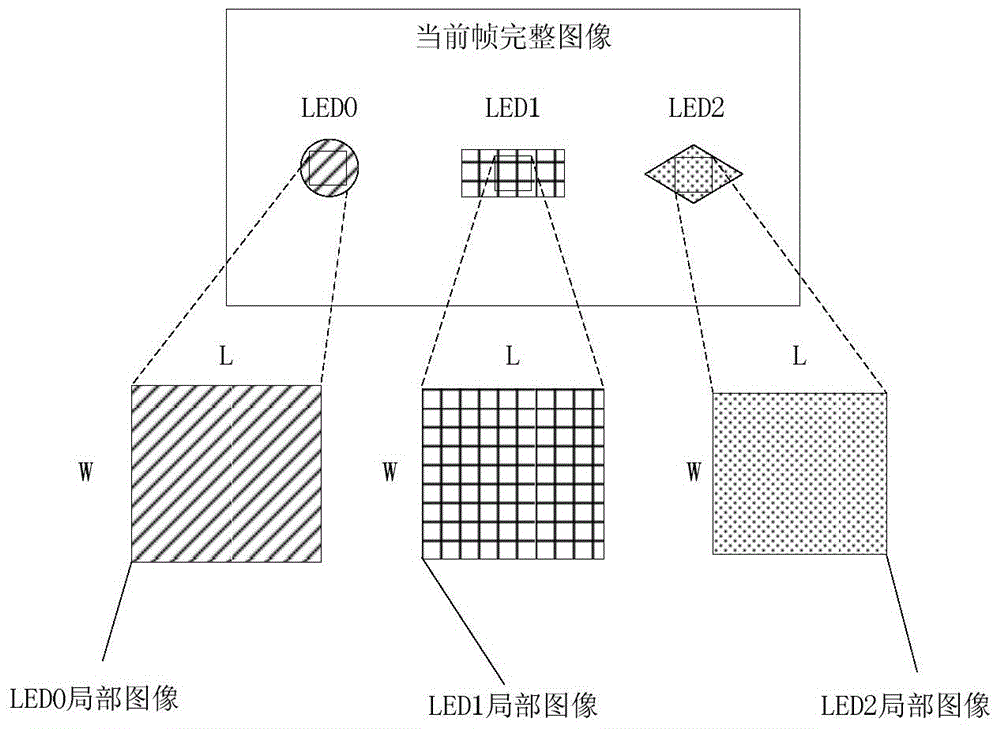

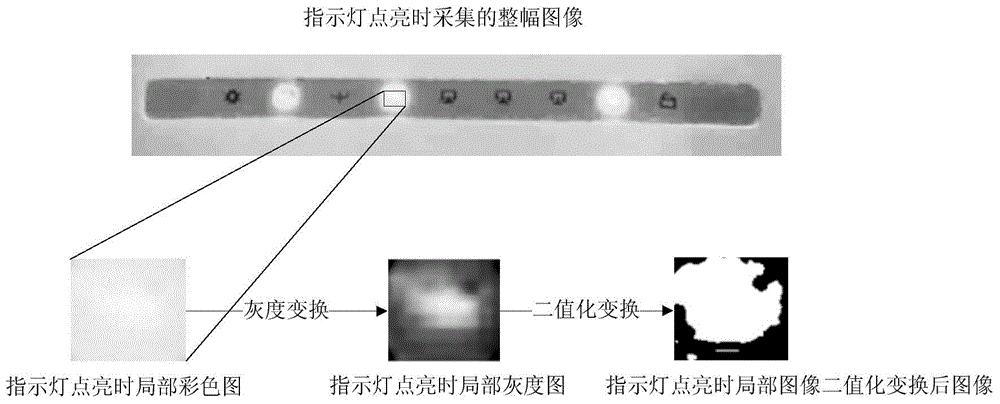

[0048] 2) Image processing and recognition: image processing is performed on each frame of image output in step 1), and the corresponding lighting and extinguishing states of the target indicator light in each frame of image are recognized;

[0049] 3) Optical state detection: Obtain the number of image frames that are continuously on or off in all identified frame images, and calculate the duration of the on state or off state, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com