Test piece guide-in mechanism of ceramic material heating thermal shock test box

A technology of impact test chamber and ceramic materials, which is applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the problems of long time, high temperature radiation of heating furnace, low efficiency, etc., and achieve the effect of accurate testing, avoiding mechanical shock and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

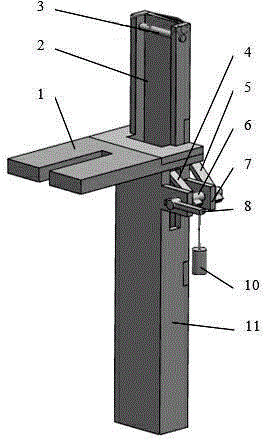

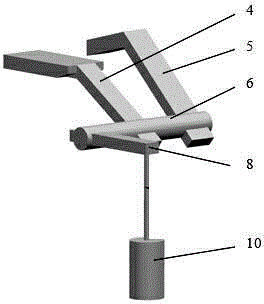

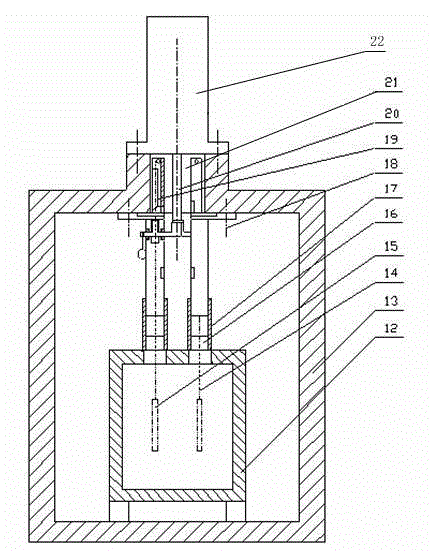

[0017] Such as figure 1 with figure 2 As shown, the present invention includes a guide cylinder 11, the upper side of the guide cylinder 11 is provided with a guide cylinder opening 2 for placing a test piece, and the lower end of the guide cylinder opening 2 is provided with a connecting lug 1 for fixing the guide cylinder 11. There are two opposite rotating shaft supports 7 on the side below the ear 1, and a rotating shaft 6 runs through the two rotating shaft supports 7. A baffle 4 is installed on the rotating shaft 6 of the guide cylinder 11, and the baffle 4 extends into the guide cylinder 11 from the notch on the side wall of the guide cylinder 11, and a counterweight suspension rod 8 is installed on the extension end of the rotation shaft 6 near the connecting lug side, and the counterweight suspension rod 8 is provided with a counterweight 10 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com