Positioning detection device for combination degree between protective sleeve and terminal

A positioning detection device and combination technology, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of increased product process costs, increased investment in testing personnel, and slow production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

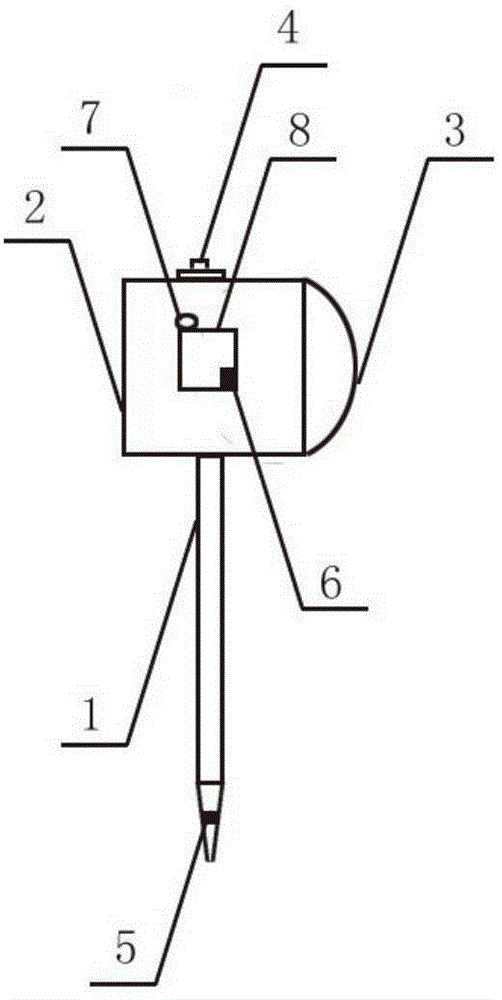

[0012] Example: as shown in the drawings. A positioning detection device for the degree of combination of a sheath and a terminal, comprising a body (1), the upper part of the body is a cylindrical structure device (2), and an annular handle (3) is arranged on the right side to facilitate the operator to fix the body (1). Set the push-type telescopic module (4), adjust the length of the lower part of the body (1) extending into the sheath, the bottom detection sensor module (5) transmits the data to the central control device (6), the central control device (6) according to the wire diameter Whether data analysis such as size and pull-out force index meets quality standards.

[0013] The utility model relates to a positioning detection device for the bonding degree of a sheath and a terminal. The body (1) has an overall appearance of a needle bar structure with a flat tip pattern at the bottom. The overall structure design is small and exquisite, and it is convenient to insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com