Probe sleeve device for ultrasonic flaw detection

A probe cover and ultrasonic technology, applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve the problem of insufficient probe coupling water, frequent replacement of wear-resistant columns, and inability to directly observe the wear of wear-resistant sleeves, etc. problems, to achieve the effects of coupling clutter suppression, service life extension, and coupling performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Referring to the accompanying drawings and embodiments, the present invention will be further described.

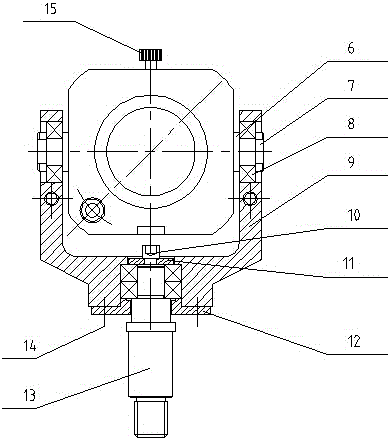

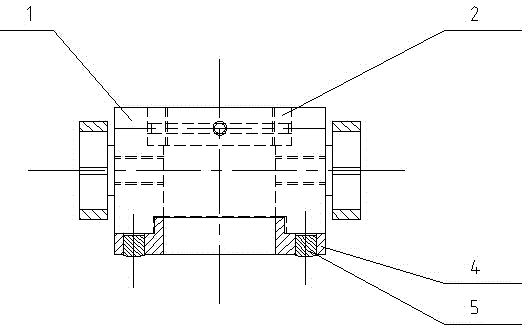

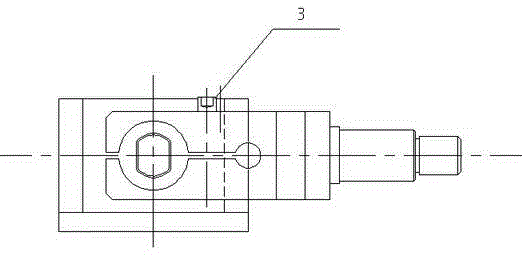

[0014] Figure 1-3 Middle: The probe rotating bracket 9 is in the shape of 'Y', and there are two stainless steel screws 3 on the top, and the two ends of the probe base 1 are connected to the upper part of the probe rotating bracket 9 through two pin shafts 7 equipped with two sealed bearings 8 respectively. Between the fork grooves of the probe base, the washer 6 is between the probe base 1 and the probe rotating bracket 9, the screw sleeve 2 is installed in the sinking platform at the upper end of the middle part of the probe base 1, the two jacking screws 15 are on the top of the probe base 1, and the wear-resistant sleeve 4 is installed in the bottom of the probe base 1, and the wear-resistant column 5 is installed in the wear-resistant sleeve 4; after the bearing is installed on the connecting shaft 13, it extends into the lower part of the fork groove of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com