Underground feed port lump ore treatment construction method based on data simulation

A large ore, data simulation technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that the crusher cannot process the open ore, delay the construction progress, affect production, etc., achieve low cost, prevent Repetition of construction and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

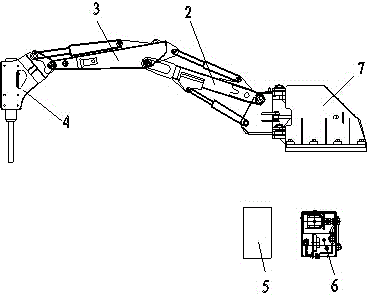

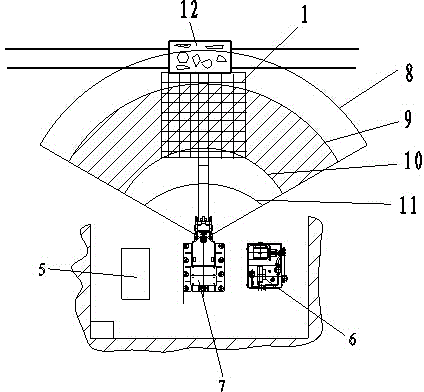

[0019] In the figure, a data simulation-based construction method for processing bulk ore at the feed inlet of the present invention is to install a grid screen at the feed inlet of the crusher, isolate the large ore on the grid screen, and install it at the attachment of the grid screen. The fixed hydraulic crusher, the large ore processing construction method includes the following construction steps;

[0020] 1) On-site data collection; survey and map the length and width of the grid screen above the ore feed port 1 and the range of the unloading and accumulation area of the rail transport trolley 12; check the size of the ore block and the hardness and composition of the ore to select the size of the hydraulic hammer. Carry out a crushing test for large ore blocks to determine the size and type of the hydraulic hammer drill rod;

[0021] 2) Simulation of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com