No-overhanging pin patch type silica gel elastic button

A patch-type, key-press technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of low production efficiency, low production efficiency, large workplaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

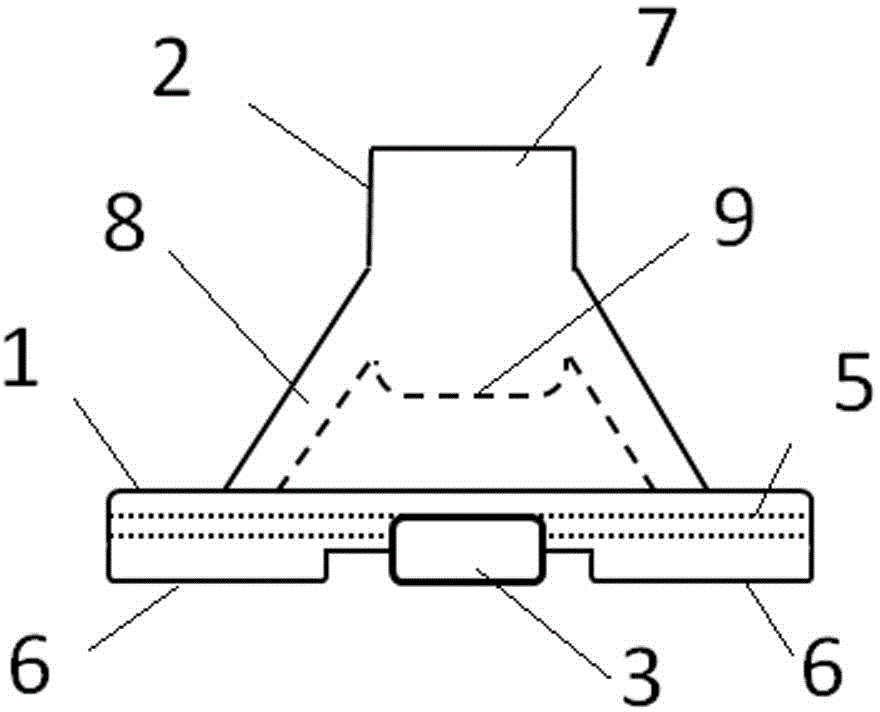

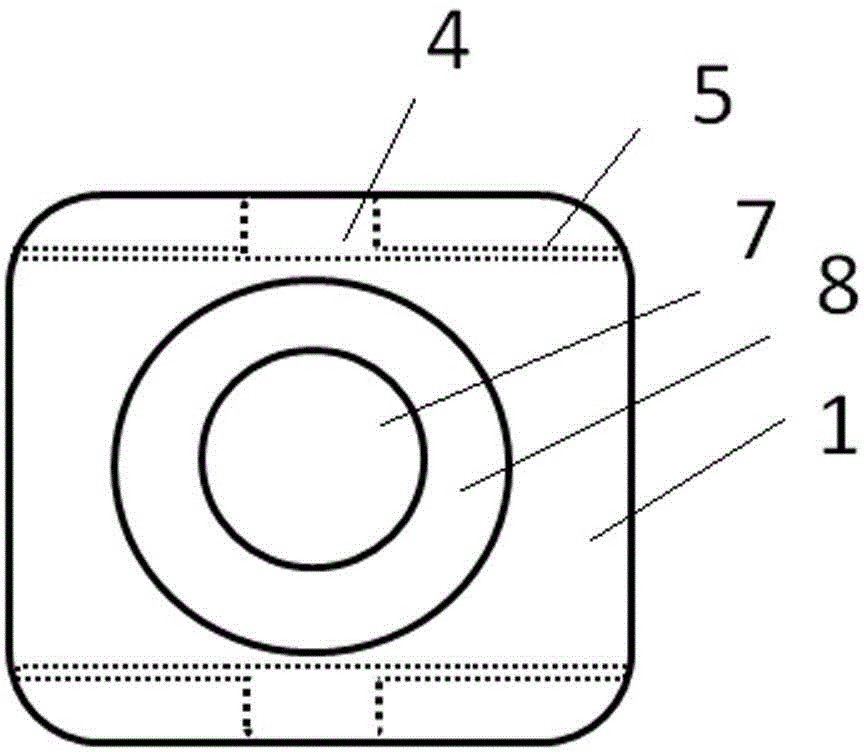

[0030] refer to Figure 1-Figure 3 , a patch-type silicone elastic button without protruding pins, comprising a base 1 and a button software 2, the button software 2 includes a button convex body 7, an elastic software 8 and a conductive contact 9, the elastic software 8 is in the shape of a tapered cylinder body shape, the inner edge of the small mouth of the elastic soft body 8 is connected with the button convex body 7, the large mouth end of the elastic soft body 8 is connected with the upper surface of the base 1, and the conductive contact 9 is arranged on the lower end surface of the button convex body 7,

[0031] The base 1 is provided with an inner pin 3 that does not exceed the outer side of the base 1 , and the lower end surface and the outer side of the inner pin 3 are welding surfaces.

[0032] The surface of the inner pin 3 is made of solderable material, which has solderability, and is convenient to play the role of solderable connection to the printed circuit b...

Embodiment 2

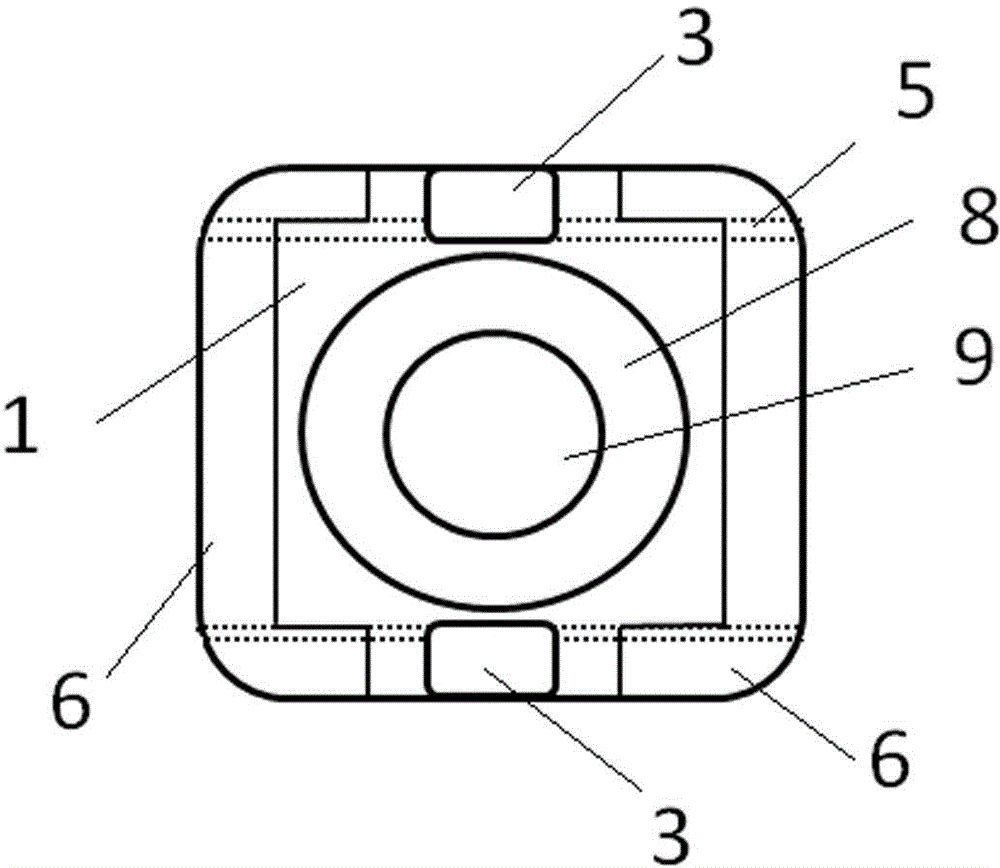

[0042] refer to Figure 4-Figure 6 , a patch-type silicone rubber elastic button without protruding pins, the number of pins 3 in this embodiment is 4, and the rest are the same as in Embodiment 1.

Embodiment 3

[0044] refer to Figure 7-Figure 9 , a patch-type silicone elastic button without protruding pins, the number of pins 3 in this embodiment is 8, and the rest are the same as in Embodiment 1.

[0045] In addition to the two, four, and eight patch-type silicone elastic buttons with inner pins 3 described in the above embodiments, by designing the symmetrical inner pins 3 of the pin bracket 4, it is possible to form different sizes, shapes and quantities. The non-extruding pin SMD silicone elastic button with pin 3 within the specification meets the needs of different products for surface mount silicone buttons with high density, low manufacturing cost, and good practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com