Device and method for automatically cleaving battery pieces

A technology of battery slices and splits, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficult debugging, failure to achieve modularization, and high control costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in more detail below in conjunction with the accompanying drawings.

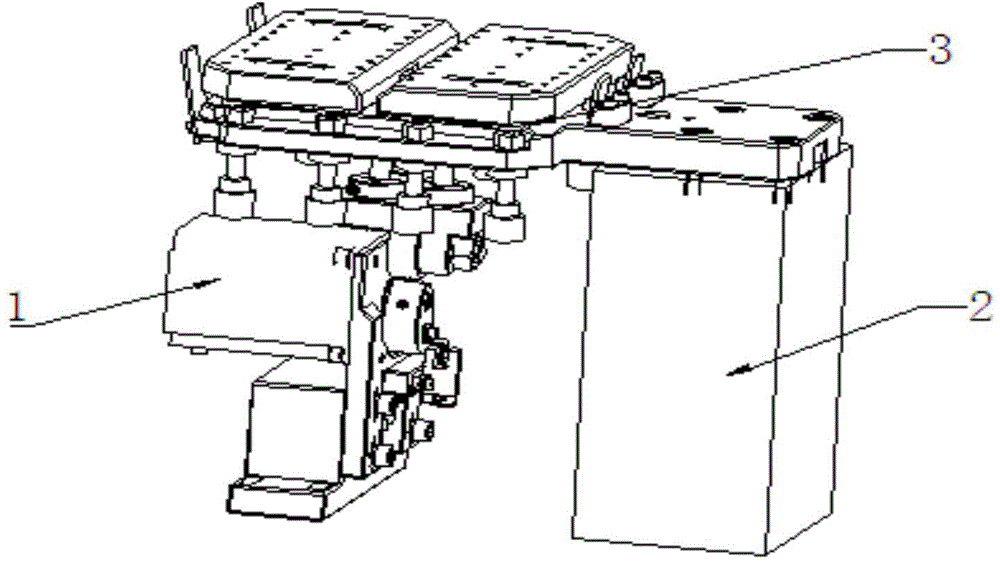

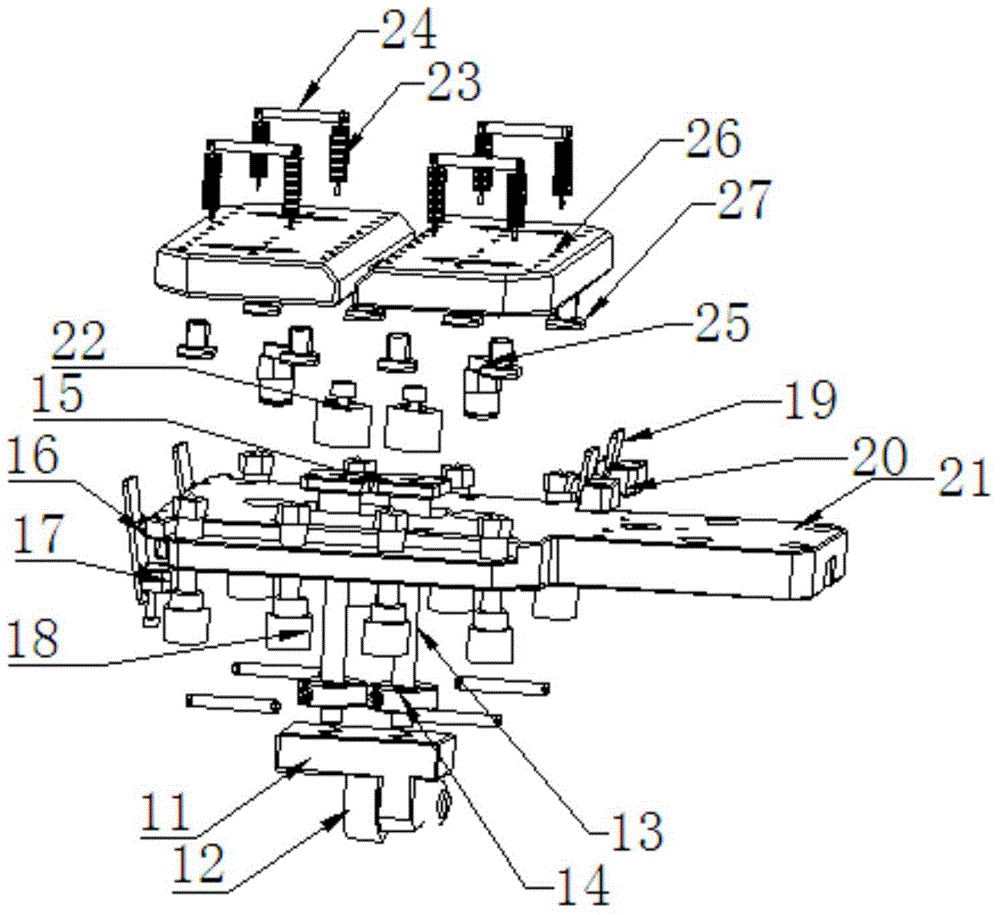

[0019] Such as figure 2 As shown: the cells after laser scribing are placed on the suction cup 26, and there is a joint 25 on the suction cup 26, and the joint 25 is connected to a negative pressure device to suck the cells. 31 turns.

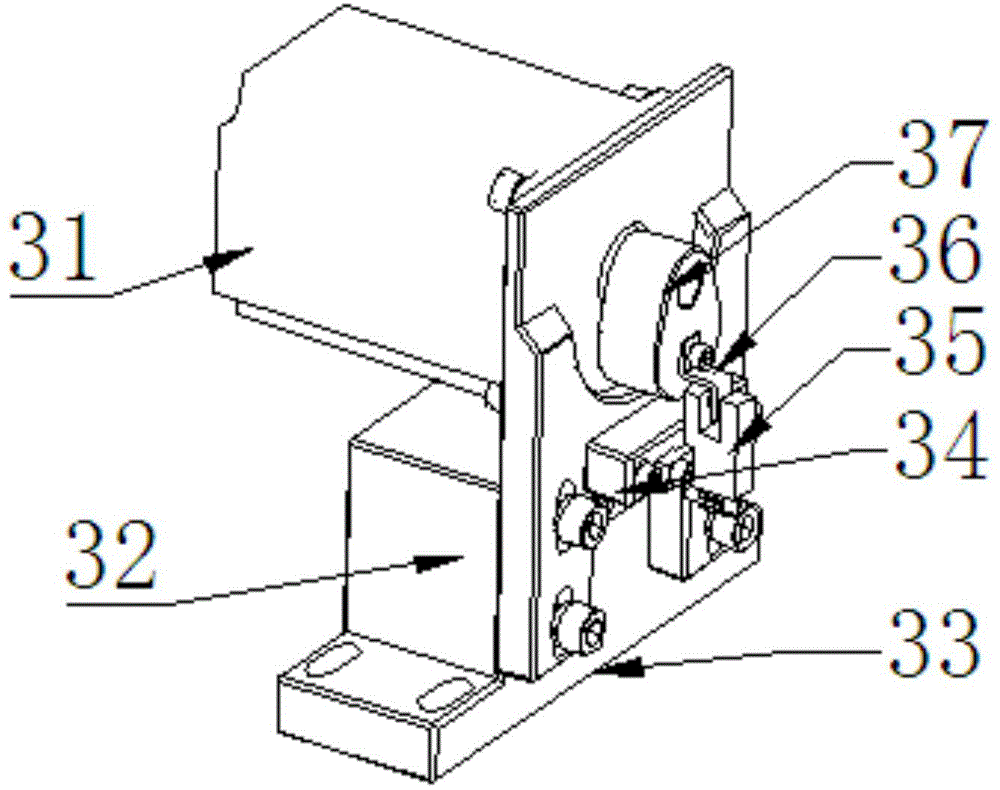

[0020] Such as image 3 As shown: the motor 31 is fixed on the motor fixing plate support 33 through the motor fixing plate 32, the rotation of the motor 31 drives the rotation of the cam 37 installed on the motor, the position sensor stopper 36 is housed on the cam 37, and the position sensor 35 passes through the sensor fixing plate 34 is fixed on the motor fixed plate 32, and after the position sensor 35 confirms that the motor 31 rotates to the lobe position, the motor 31 stops. The cam 37 lifts the guide rod 13 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com