Integral greening system of external building wall

An integral technology for building exterior walls, applied in container cultivation, horticulture, botanical equipment and methods, etc., can solve the problems of high maintenance cost, monotonous overall effect, and sparse plant species.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

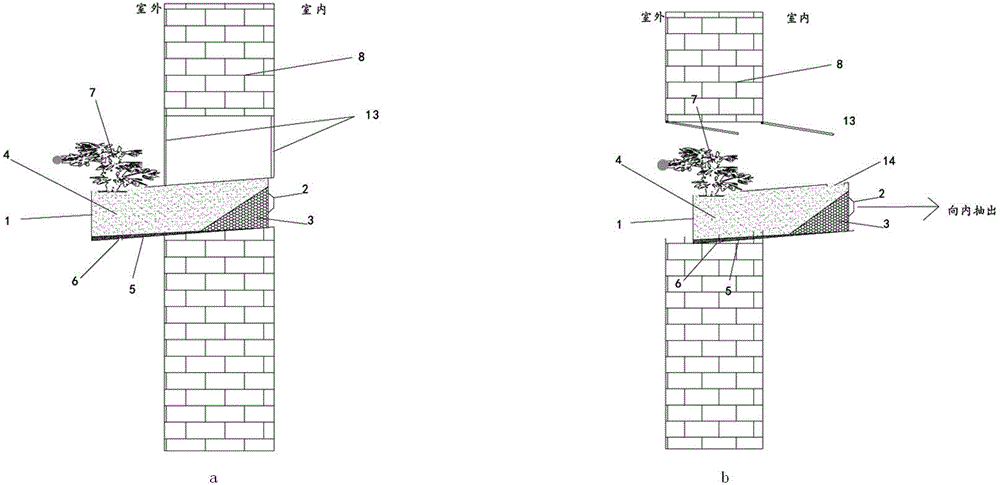

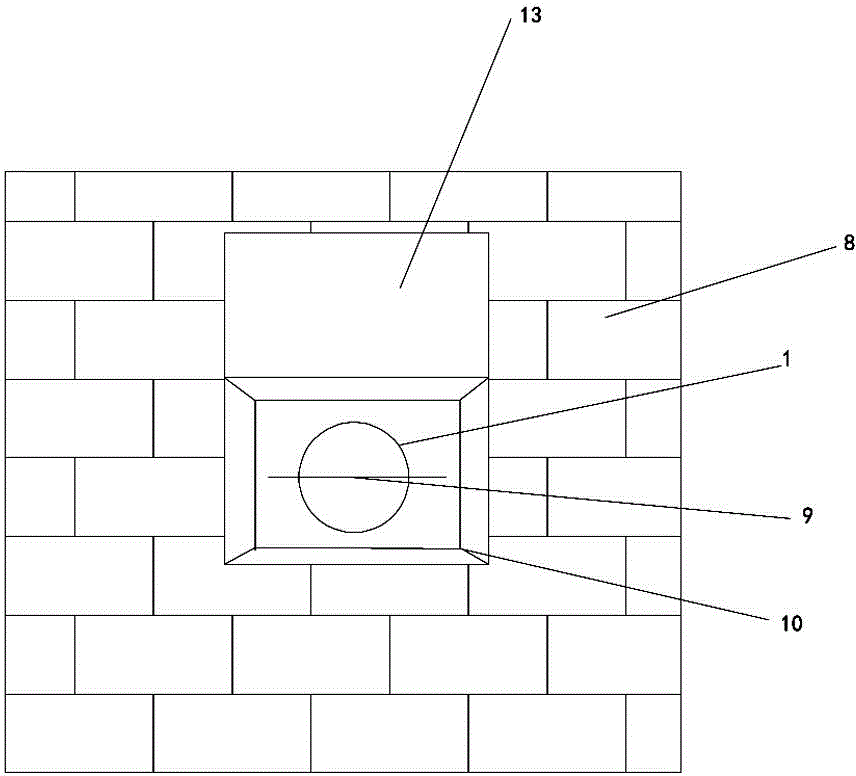

Method used

Image

Examples

Embodiment 2

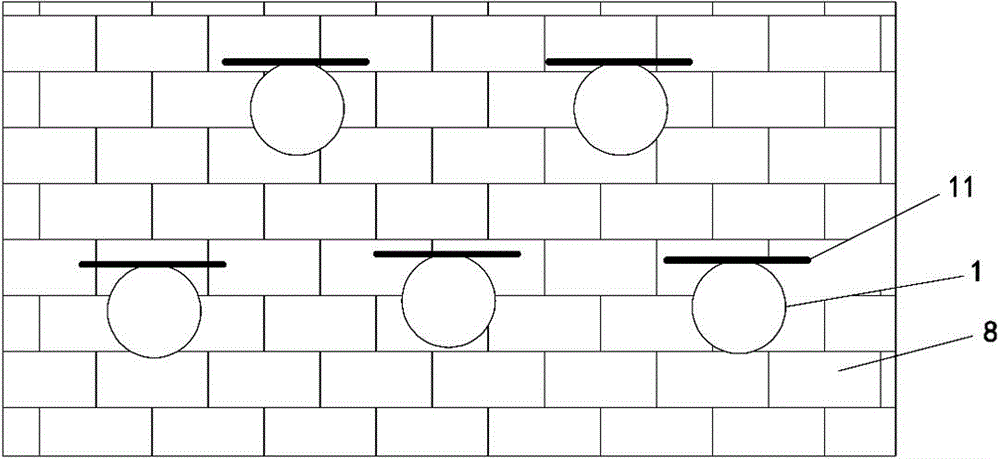

[0026] To replace the load-bearing integral scissors wall with a non-load-bearing exterior wall, a crossbeam strapping plate is set above the planting hole 12 of the non-load-bearing exterior wall. The said crossbeam board can be fine steel concrete thin board, wood board, bamboo board or steel bar. The overall structure of the planting holes of the non-load-bearing exterior wall can be arranged in a plum blossom shape, or in the shape of a Mercedes-Benz car logo, or in the shape of a Honda car logo, a character shape, or a Lexus car logo.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com