Precise pesticide sprayer for hillside orchards

A pesticide spraying machine and mountain technology, applied to the device for capturing or killing insects, application, animal husbandry, etc., can solve the problems of low utilization rate of pesticides, poisoning of operators, high labor intensity, etc., to avoid waste and pollution, The effect of avoiding waste and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific implementation the present invention will be further described:

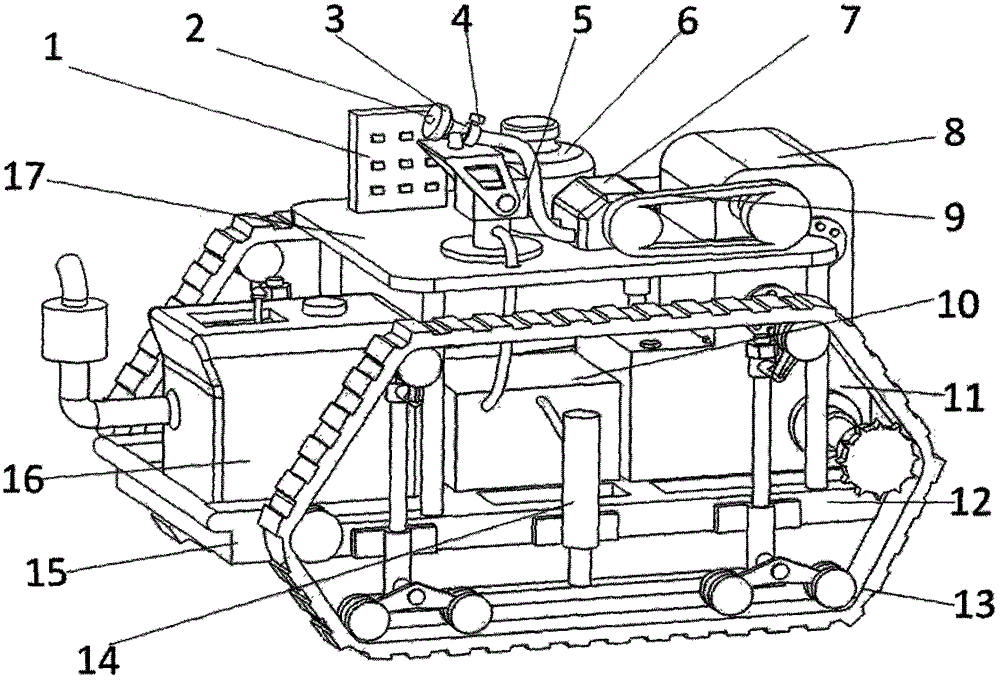

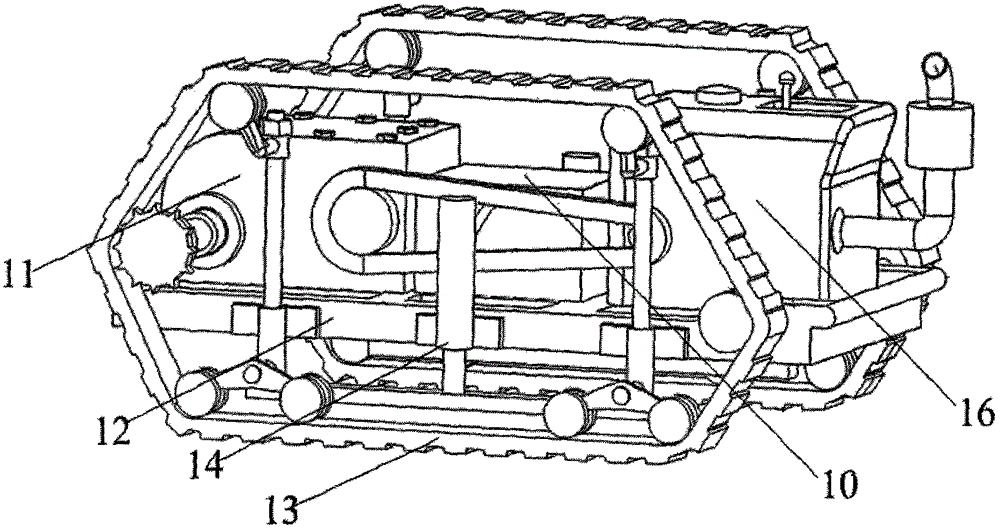

[0015] figure 1 and figure 2 Shown the embodiment of the present invention, this mountain orchard precision spraying machine comprises: mountain tractor (15), instrument rack (17), controller (1), infrared emitter (2), sprinkler head (3), flow control Valve (4), small hydraulic head (5), pesticide box (6), pump (7), power box (8), belt (9), hydraulic system (10), gearbox (11), frame ( 12), crawler-type traveling mechanism (13), hydraulic differential height device (14), engine (16);

[0016] The instrument frame (17) is fixed on the frame (12) by bolts; the pesticide box (6) is fixed on the instrument frame (17), and the pesticide is sent to the pump (7) by the water pipe, and the pesticide is pressurized The nozzle (3) is sent to the nozzle (3) by the water pipe; the nozzle (3) is fixed on the small hydraulic platform (5), and the infrared e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com