Gas-liquid-liquid three-phase separator for testing apparatus

A technology of three-phase separator and test device, which is applied in the direction of liquid separation, separation method, liquid degassing, etc., can solve the problem of not being able to collect fresh samples in time, and achieve the effect of eliminating human interference, reducing labor intensity, and fresh samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

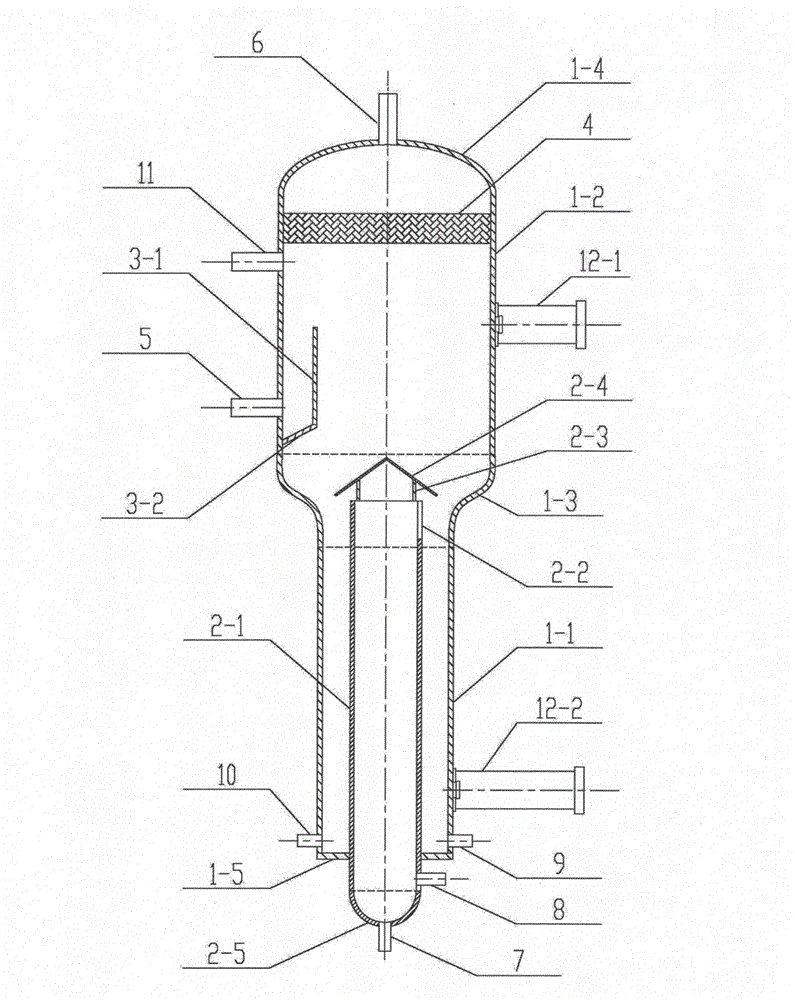

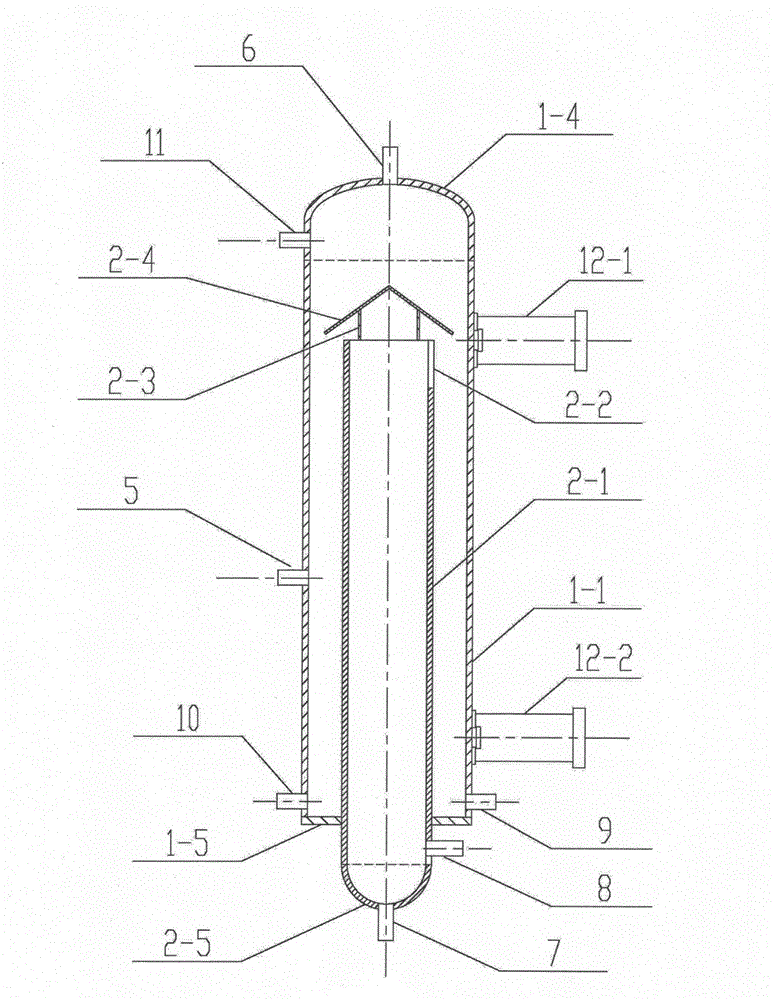

[0018] The invention is a gas-liquid-liquid three-phase separator for a test device, such as figure 1 As shown, it includes a cylinder body, the cylinder body includes a lower cylinder body 1-1, the lower end of the lower cylinder body 1-1 is sealed and connected with the lower sealing plate 1-5 and the inner casing 2-1, and the lower cylinder body 1-1 The upper end of the upper cylinder is connected with the lower end of the upper cylinder 1-2 through the big and small head pipe fittings 1-3, and the upper end of the upper cylinder 1-2 is connected with the gas phase outlet 6 through the upper head 1-4. There is a demister 4 in the cylinder near the gas phase outlet 6, and a baffle 3-1 is installed below the position of the feed port 5 on the cylinder inner wall, and the baffle 3-1 is connected with the cylinder inner wall throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com