Automatic spraying device

A technology of automatic spraying and spraying equipment, which is applied in coatings, spray booths, spraying devices, etc., can solve the problems of increased cleaning fluid material loss, poor product operation stability, and paint splashing, achieving ingenious design, cost reduction, and reduction damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

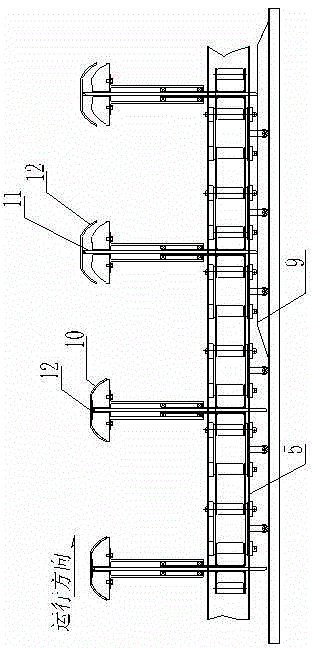

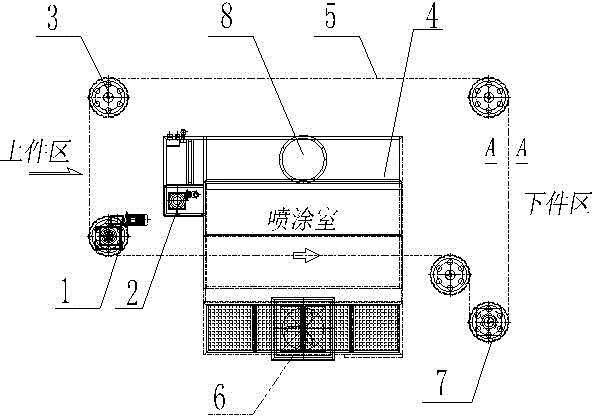

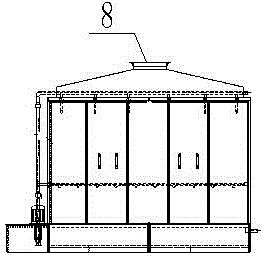

[0015] see figure 1 , a kind of automatic spraying equipment, described spraying equipment comprises drive unit 1, conveyer chain 5, the passive pulley 3 that is arranged on conveyer chain 5 and tensioning device 7, described spraying equipment also comprises spraying room 4, described spraying room 4 is provided with an exhaust port 8 above, a blower 6 is provided in the spraying room, and a water pump 2 is provided on one side of the spraying room; the spraying equipment also includes a product mold 10, and the product mold 10 is provided with a push rod 11, Product molds 10 are placed on the conveyor chain 5 . When working, the product is placed on the product mold 10, so that the product can run smoothly during the spraying process. The product mold 10 is designed to be the same shape as the product. When spraying the product, the paint particles will not be splashed into the product. The ejector pin 11 is set on the mold 10, and in the lower part area, the slope track 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com