Spannfutter

A chuck and disk body technology, applied in the directions of large fixed members, clamping, and support, can solve the problems of inability to automate and lose accuracy, and achieve the effect of small simplicity, avoidance of bending, and avoidance of loss of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

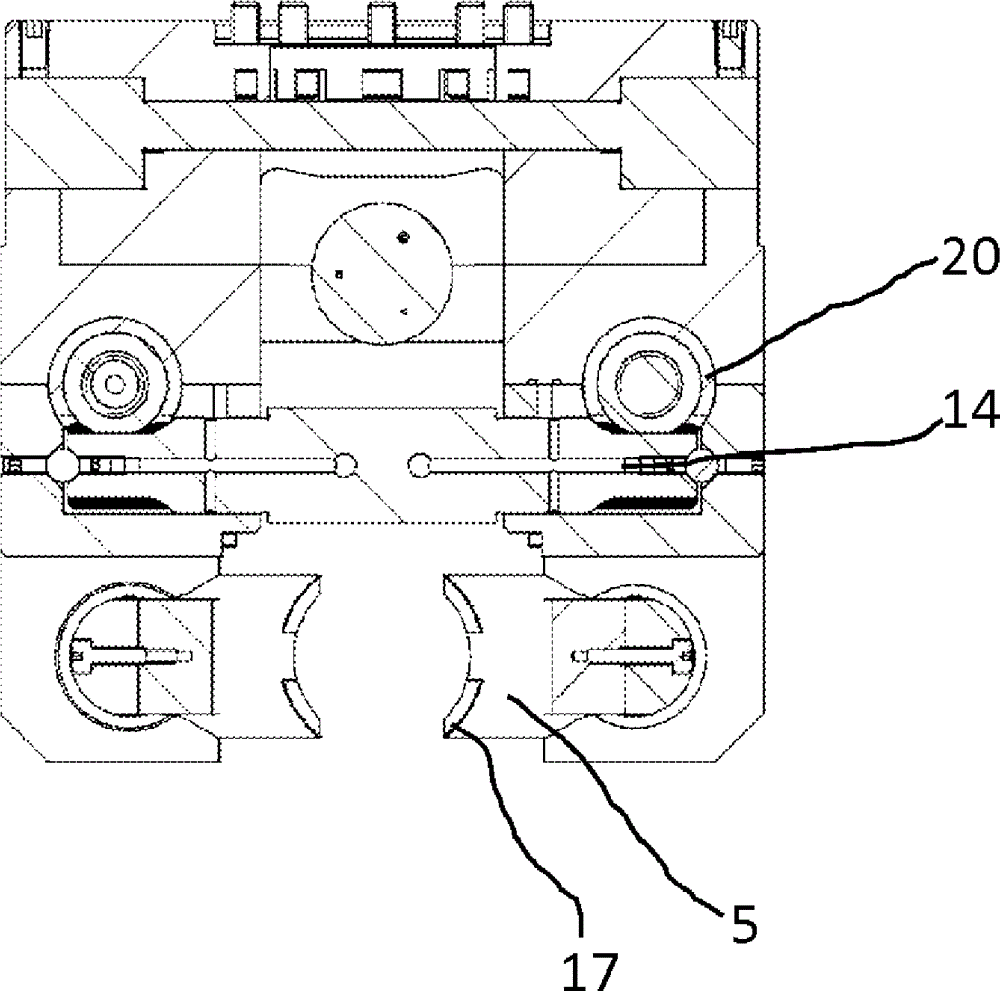

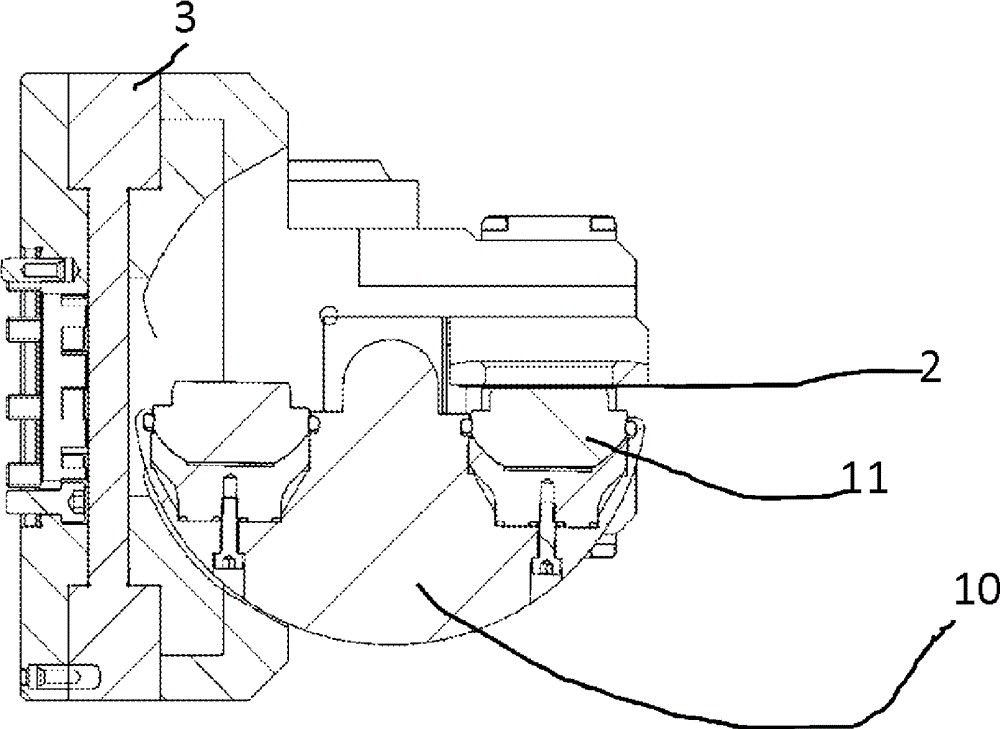

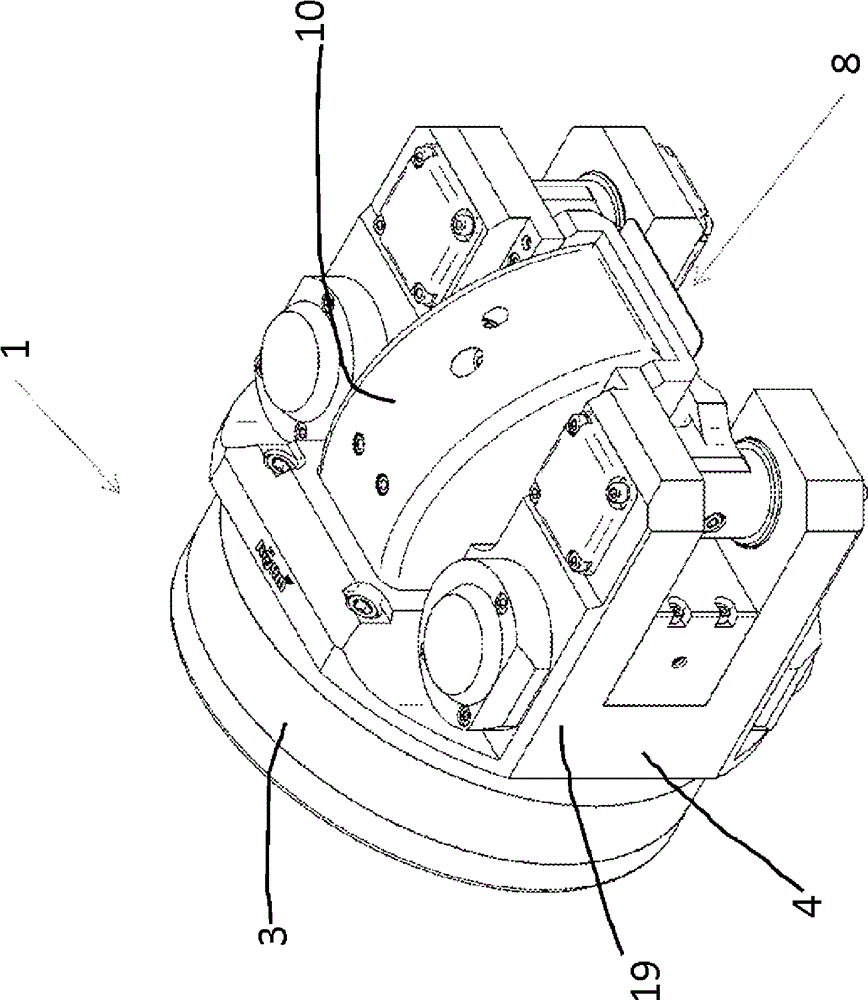

[0024] In the attached picture, figure 1 A chuck 1 is shown, which is used for clamping thin-walled workpieces 2 , ie, in the exemplary embodiment shown in the drawing, for clamping thin-walled printed circuit boards. The chuck 1 has a disc body 3 on which two U-shaped brackets 4 are arranged, and clamping blocks 5 are arranged between the free ends of these brackets, and the clamping blocks are used for clamping the workpiece 2 . A workpiece carrier 6 is assigned to the disk body 3 , that is, in the exemplary embodiment shown in the drawing, between the free ends of the U-shaped brackets 4 . The clamping block 5 is designed as a clamping pin which can be adjusted perpendicular to the plane of the workpiece carrier 6 .

[0025] The disk 3 can be adjusted between a first rotational position for machining the upper side 7 of the workpiece 2 and a second rotational position for machining the lower side 8 of the workpiece. In order that the workpiece 2 can be reached by the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com