Processing method of polymer pipe for intravascular stent

A technology for polymer tubes and vascular stents, applied in the field of medical devices, can solve the problems of low fracture strength, small radial support force, and poor mechanical properties of stents, so as to improve the fracture strength and increase the radial support force. , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

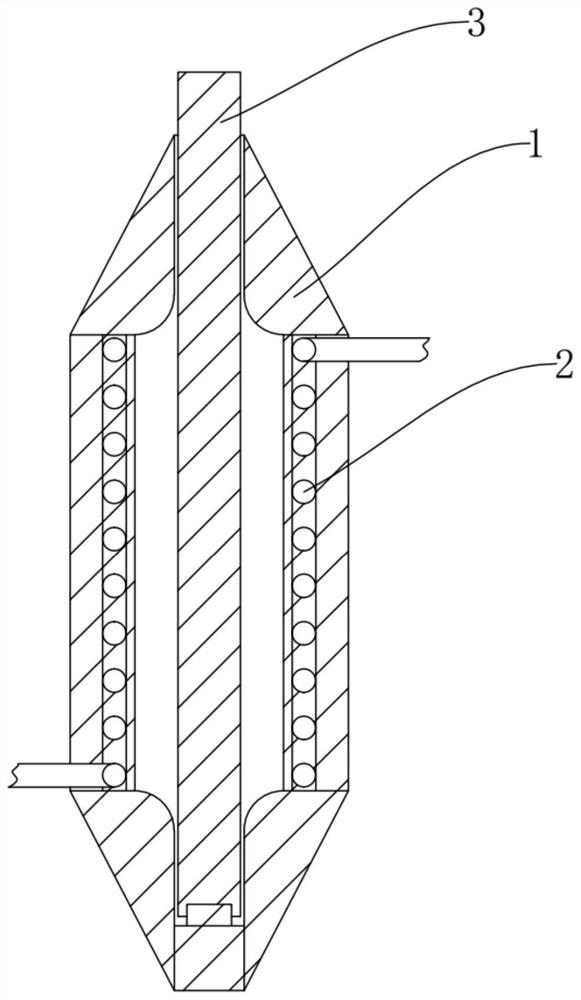

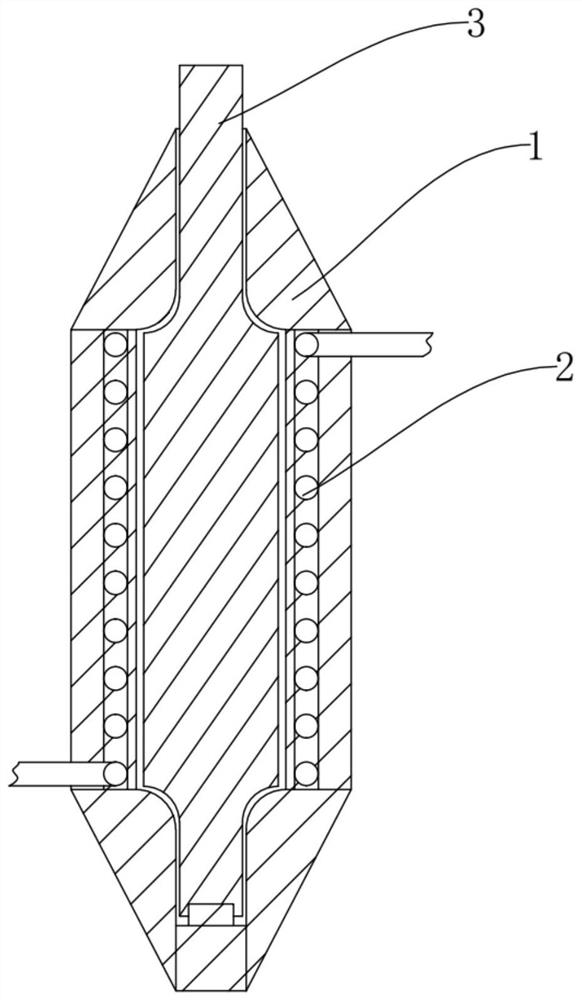

[0023] (a) Heat the extruded polylactic acid polymer pipe 3 to 55°C, the polymer pipe 3 softens, and keep it warm at the 55°C for 20min, the wall thickness of the polymer pipe 3 is 500um;

[0024] (b) Put the heated polymer pipe 3 into the cavity of the mold 1 quickly, and feed hot air at 55°C at a constant speed into the polymer pipe 3, and the pipe 3 in the cavity is heated by the hot air. under the action of expansion and deformation in the radial direction, and the outer wall of the expanded pipe 3 is attached to the inner wall of the mold 1;

[0025] (c) Open the circulating cooling water in the mold 1, and pass cold air at 20°C into the pipe 3. The cold air inside the mold 1 and the pipe 3 with a lower temperature acts on the pipe 3 at the same time, and the pipe 3 is quickly cooled. The heat is taken away, so that the pipe material 3 is rapidly cooled to room temperature, and the mold is opened to obtain a deformed pipe material 3 with a wall thickness of 100um.

[002...

Embodiment 2

[0029] (a) Heat the extruded polylactic acid polymer pipe 3 to 60°C, the polymer pipe 3 softens, and keep it warm at the temperature of 60°C for 10 minutes, and the wall thickness of the polymer pipe 3 is 600um;

[0030] (b) Put the heated polymer pipe 3 into the cavity of the mold 1 quickly, and feed hot air at 60°C at a constant speed into the polymer pipe 3, and the pipe 3 in the cavity is heated by the hot air. under the action of expansion and deformation in the radial direction, and the outer wall of the expanded pipe 3 is attached to the inner wall of the mold 1;

[0031] (c) Open the circulating cooling water in the mold 1, and pass cold air at 20°C into the pipe 3. The cold air inside the mold 1 and the pipe 3 with a lower temperature acts on the pipe 3 at the same time, and the pipe 3 is quickly cooled. The heat is taken away, the pipe 3 is quickly cooled to room temperature, and the mold is opened to obtain the deformed pipe 3 with a wall thickness of 200um.

[003...

Embodiment 3

[0035] (a) Heat the extruded polylactic acid polymer pipe 3 to 65°C, the polymer pipe 3 softens, and keep it warm at 65°C for 10 minutes, and the wall thickness of the polymer pipe 3 is 500um;

[0036] (b) Put the heated polymer pipe 3 into the cavity of the mold 1 quickly, and feed hot air at 70°C at a constant speed into the polymer pipe 3, and the pipe 3 in the cavity is heated by the hot air. under the action of expansion and deformation in the radial direction, and the outer wall of the expanded pipe 3 is attached to the inner wall of the mold 1;

[0037] (c) Turn on the circulating cooling water in the mold 1, and pass cold air at 25°C into the pipe 3. The cold air inside the mold 1 and the pipe 3 with a lower temperature acts on the pipe 3 at the same time, and the pipe 3 will be quickly The heat is taken away, so that the pipe material 3 is rapidly cooled to room temperature, and the mold is opened to obtain a deformed pipe material 3 with a wall thickness of 100um.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com