A multi-hardness splicing hardened steel concave surface test piece and the processing technology of the concave model surface

A hardened steel, multi-hardness technology, which is applied to milling cutter specimens and milling cutter concave model surface processing technology, multi-hardness splicing hardened steel concave curved surface specimens and concave model surface processing technology fields, can solve the problem that the concave model cannot be satisfied. Surface processing quality requirements, unreasonable milling process design, and high surface roughness values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

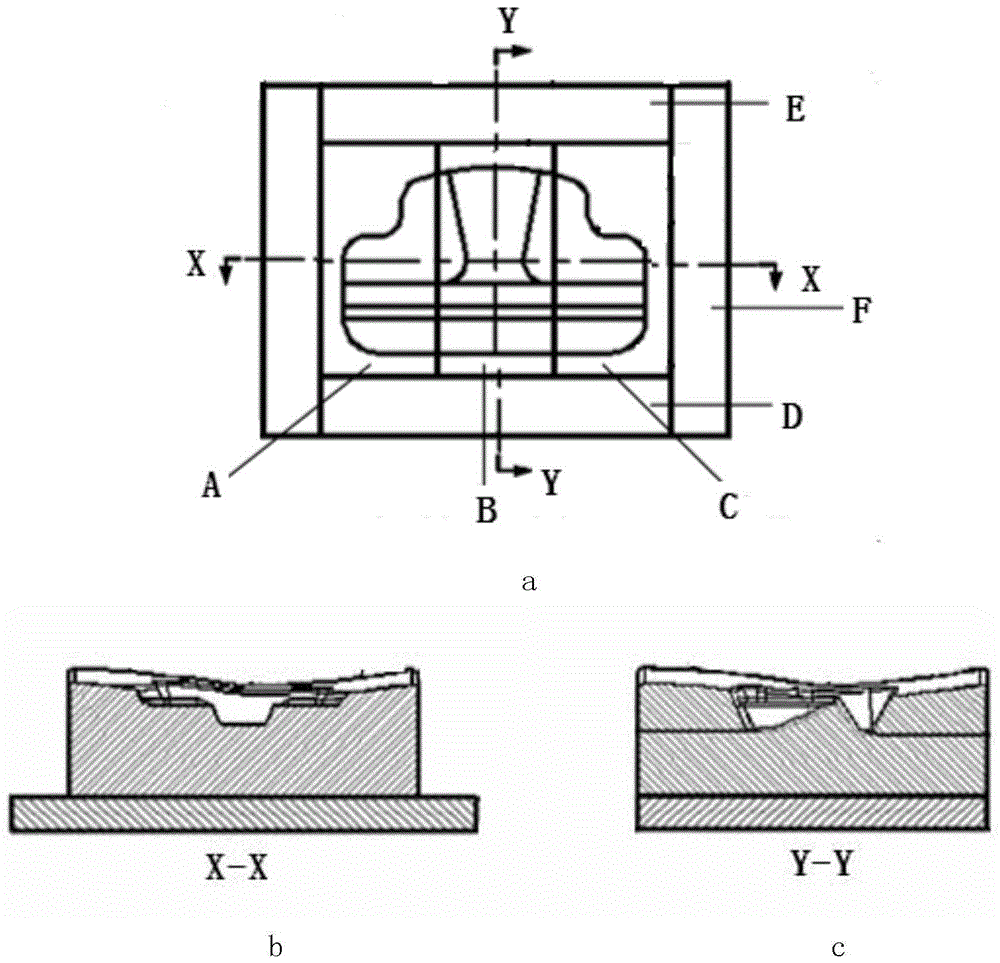

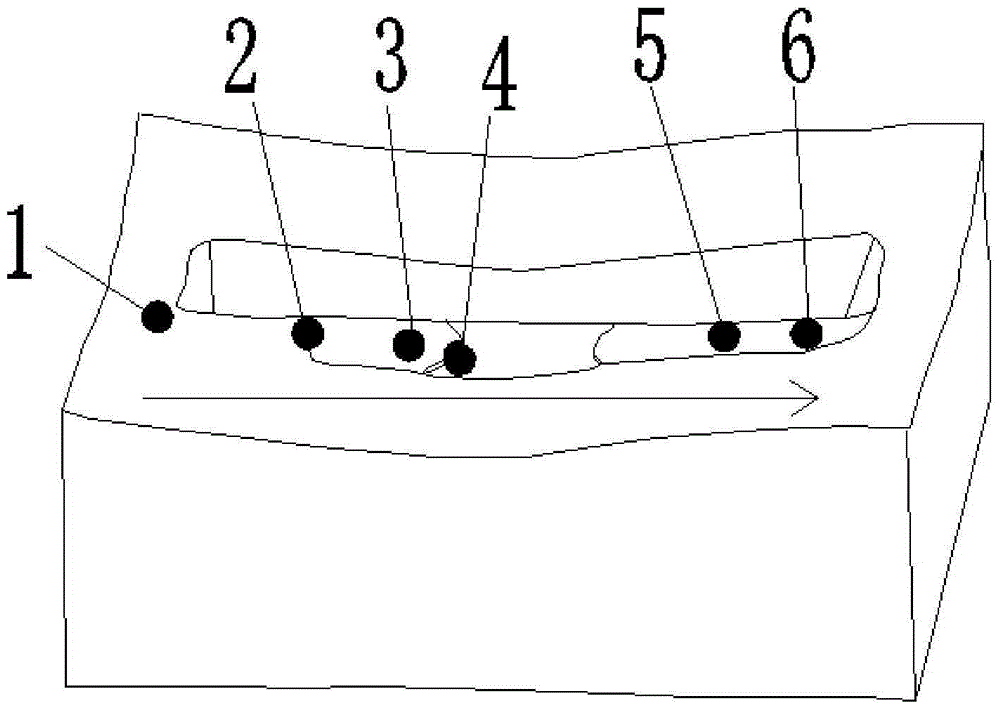

[0040] The specific embodiment of the present invention is described in conjunction with the accompanying drawings. A multi-hardness spliced hardened steel concave curved test piece of the present invention is a cuboid structure with an outline size of 400mm×300mm×138mm, such as figure 1As shown, including the first part A, the second part B, the third part C, the fourth part D, the fifth part E and the sixth part F, the first part A, the second part The lower surface of part B, the third part C, the fourth part D and the fifth part E are connected with the upper surface of the sixth part F through positioning pins and fastening screws, the fourth part D and the fifth part The fifth part E is installed on the upper end surface of the sixth part F parallel up and down, the length of the fourth part D and the fifth part E are the same, the first part A, the second part B and the third part The parts C are arranged in sequence in the groove formed by the fourth part D, the fift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com