Agricultural sprayer

A sprayer and container technology, applied in the field of small agricultural spraying drones, can solve the problems of slow response speed, serious power consumption, inconvenient shipping, etc., and achieve the effects of fast response speed, strong wind resistance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

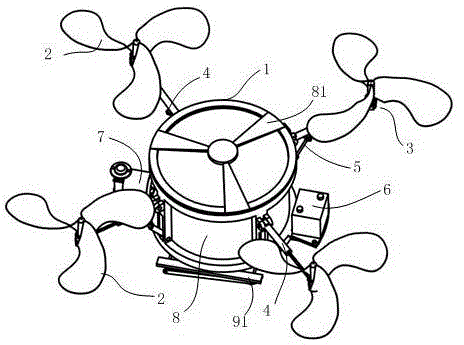

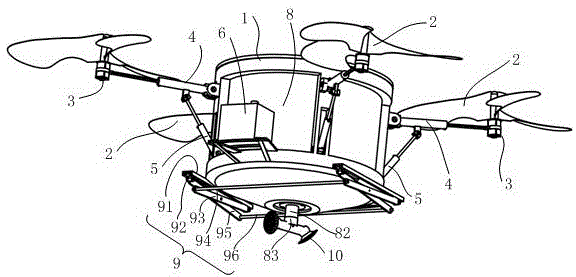

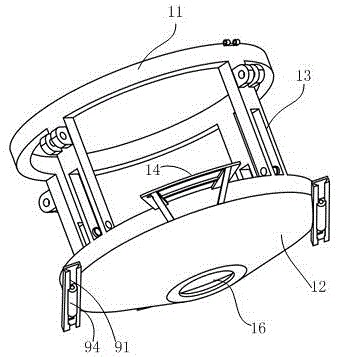

[0013] Implementation mode 1, see Figure 1-3 .

[0014] An agricultural powder material sprayer, comprising a frame 1, four rotors 2, and rotor motors 3 respectively arranged under each rotor 2, the frame 1 is in the shape of a cage as a whole, and the upper part is a ring beam 11, the lower part is a circular basin bottom 12, and the middle part of the circular basin bottom 12 is provided with a through hole 16; four columns 13 connect the circular ring beam 11 and the circular basin bottom 12 as a whole and follow the circular ring beam 11 or the circle The circumference of the shaped basin bottom 12 is evenly distributed, the upper end of each column 13 is hinged to one end of the first cylinder 4, the lower end of each column 13 is hinged to one end of the second cylinder 5, and the other end of the first cylinder 4 is fixed to the rotor motor 3 , the motor shafts of the four rotor motors 3 are respectively fixed to 4 and the rotor 2, the opposite two rotors have the sam...

Embodiment approach 2

[0016] Implementation mode 2, see Figure 1-3 .

[0017] An agricultural liquid material sprinkler, the other is the same as Embodiment 1, the difference is that the solenoid valve 83 is connected to the nozzle 10, the landing gear 9 includes a dovetail-shaped landing gear seat 91 with the opening downward, and a first hinged joint at one end and the middle part of the dovetail groove. Three cylinders 94, the slide block 92 that the two ends of the dovetail groove are matched respectively, the first support 93 and the second support 95 that one end is respectively hinged with two slide blocks 92, the middle part of the first support 93 and the second support 95 is hinged, the third The other end of cylinder 94 is hinged with the upper section of first support 93 or second support 95, and the other end of two first supports 93 and two second supports 95 is connected by connecting rod 96 respectively, and the air outlet of miniature air compressor 7 It communicates with the cyl...

Embodiment approach 3

[0020] Implementation mode 3, see Figure 1-3 .

[0021] Others are the same as Embodiment 2, except that the outer surfaces of the container 8 and the sealing cover 81 are covered with solar panels. The solar panel is connected to the battery 6 . Since pesticides and fertilizers are mostly sprayed on sunny days, the electric energy converted by solar panels can be stored in batteries to prolong flight time and reflect the concept of green environmental protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com