A system for ensuring normal shutdown and blowing of sulfur during sulfur recovery

A technology for normal shutdown and sulfur recovery, applied in the field of sulfur recovery, can solve the problems of insufficient sulfur blowing time, system and equipment damage, etc., to reduce costs and ensure system safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

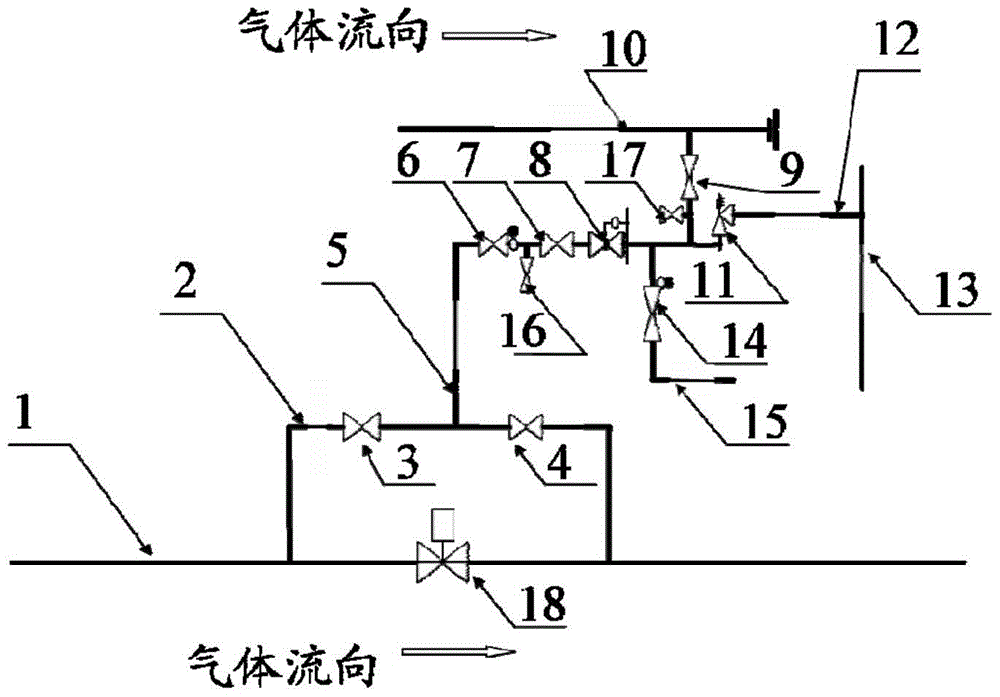

[0032] The present invention will be further described below through specific examples, but it should be understood that these examples are only used for more detailed description, and should not be construed as limiting the present invention in any form. It will be clear to those skilled in the art that in the context, if not specifically stated, the valves and components used in the present invention are well known in the art.

[0033] Such as figure 1 As shown, the present invention provides a system for ensuring normal shutdown and sulfur blowing during the sulfur recovery process, the system includes a fuel gas pipeline 10, a vent flare pipeline 13, a natural gas external transportation pipeline 1, a pressure equalization pipeline 2 connected in parallel with it, a set The pressure equalizing valve 3 and the pressure equalizing valve 4 on the said equalizing pipeline, said system also includes:

[0034] In the flow direction of the gas in the pressure equalization pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com