Disc valve with mechanical linkage of main and auxiliary valves

A disc valve, mechanical technology, applied in mechanical equipment, valve operation/release device, valve details, etc., can solve the problem of pressure in the valve cavity, the speed of material accumulation in the middle cavity does not allow the purge port, and the valve cannot be opened normally, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

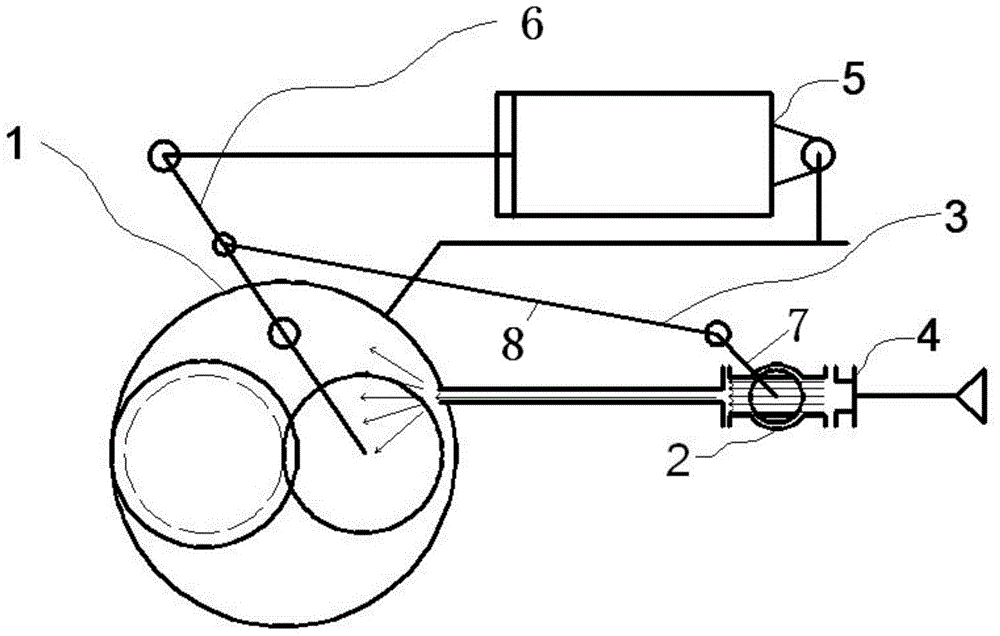

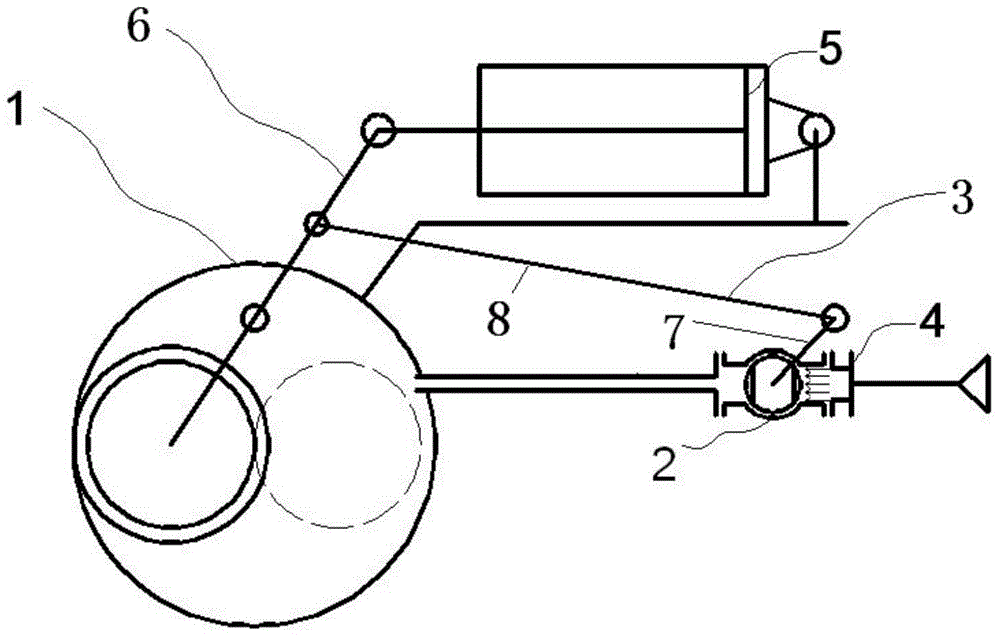

[0022] The disc valve with mechanical linkage of main and auxiliary valves according to the present invention is an eccentric rotary structure, which includes a main valve 1, an auxiliary valve 2, a mechanical linkage system 3, an external gas system 4, etc., the main valve 1 and the auxiliary valve 2 are mechanically connected to each other. The linkage system 3 is connected, the external gas system 4 is connected with the auxiliary valve 2, and the main valve 1 is driven to act by the actuator 5 .

[0023] Such as figure 1 , figure 2 As shown, the main valve 1 is an angular stroke (for example: Patent No. ZL200920163663.X), and the rotation angle of the main valve 1 is 50-70° (for example: 50°, 60° or 70°) for the full stroke. The auxiliary valve 2 is a ball valve, and the rotation angle of the full stroke is 90°.

[0024] Mechanical linkage system 3 is based on the principle of four-bar mechanism, including rod one 7, rod two 8 and rocker arm 6; wherein, one end of rod o...

Embodiment 2

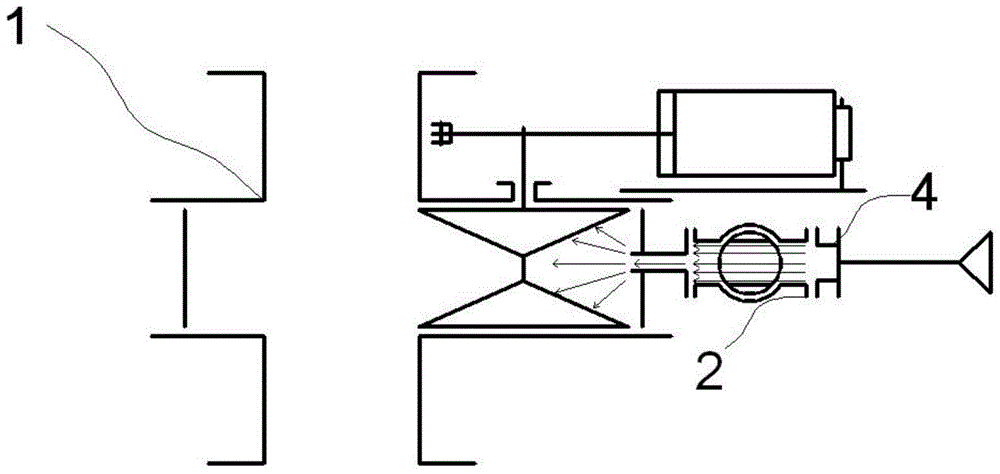

[0030] The disc valve with mechanical linkage of main and auxiliary valves according to the present invention is an eccentric rotary structure, which includes a main valve 1, an auxiliary valve 2, a mechanical linkage system 3, an external gas system 4, etc., the main valve 1 and the auxiliary valve 2 are mechanically connected to each other. The linkage system 3 is connected, the external gas system 4 is connected with the auxiliary valve 2, and the main valve 1 is driven to act by the actuator 5 .

[0031] Such as Figure 5 , 7 As shown, the main valve 1 is a straight-stroke valve (for example: Patent No. US5396919), and the auxiliary valve 2 is also set as a straight-stroke valve.

[0032] The mechanical linkage system 3 is an L-shaped fork structure. The middle of the L-shaped fork structure is set on the fixed point 10. One end of the L-shaped fork structure is connected to the valve stem of the auxiliary valve 2. The L-shaped fork structure There is a slot 9 at the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com