A heat pipe type photovoltaic power generation heat collection component

A technology of photovoltaic power generation and heat collection components, applied in photovoltaic power generation, photovoltaic thermoelectric hybrid power generation, solar thermal power generation, etc., can solve the problems of increased roof load, large power consumption, and decreased thermal efficiency, and reduce wind load and load-bearing load , Improve overall performance and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

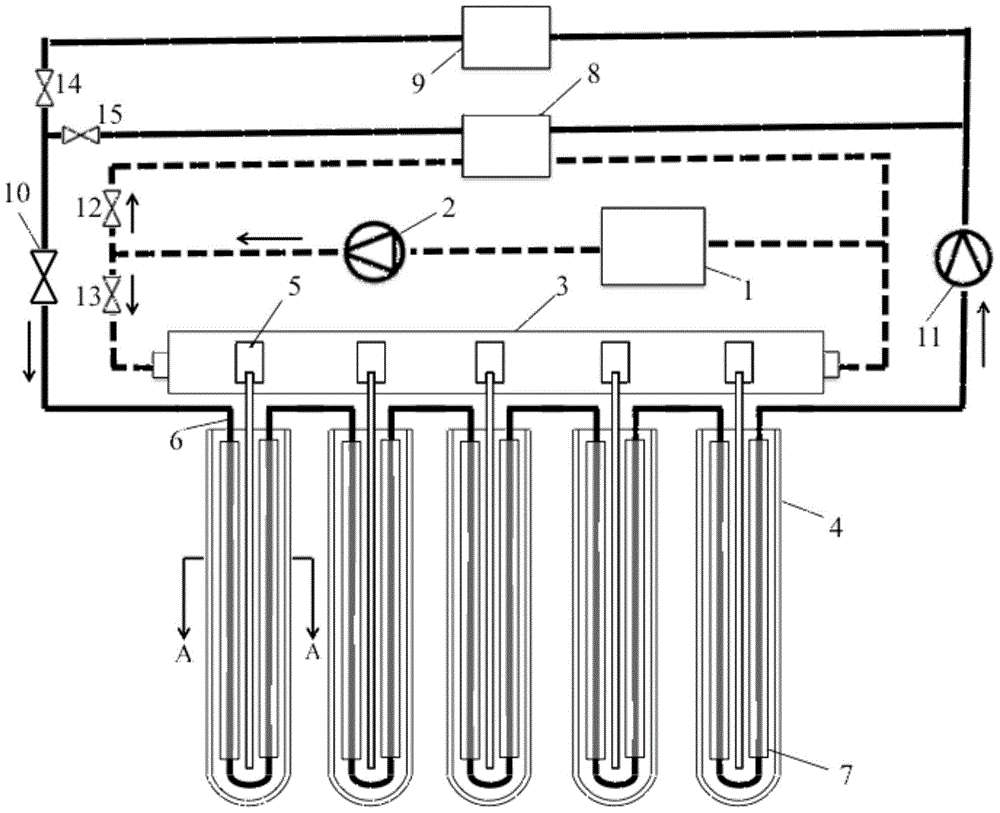

[0022] Concrete technical scheme of the present invention is:

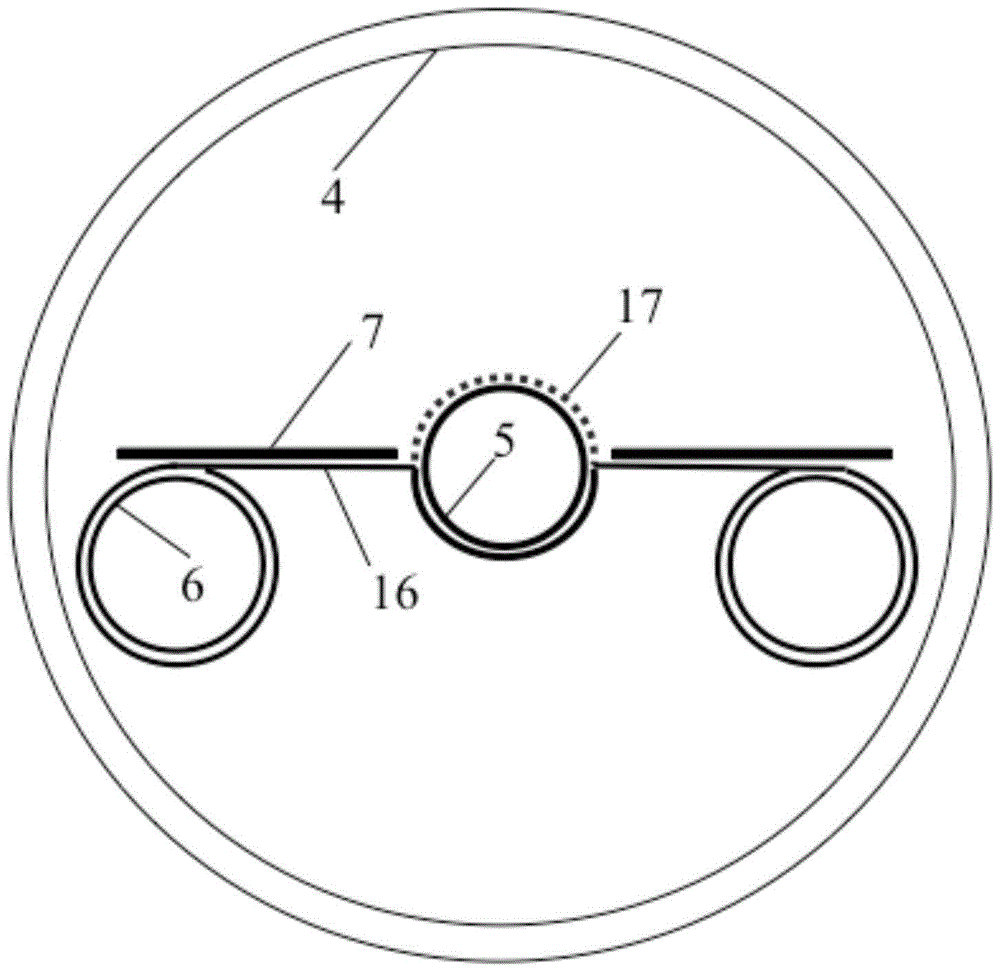

[0023] See attached figure 2 , a heat pipe-type photovoltaic power generation heat collection assembly, mainly including a double-glass vacuum tube 4, an aluminum plate 16, a photovoltaic plate 7, a U-shaped copper tube 6 and a heat pipe 5. Roll up the two ends of the longitudinal length of the aluminum plate 16 downwards, respectively tightly clamping one side of the U-shaped copper tube 6, and the middle of the aluminum plate 16 is an upward concave arc to clamp the heat pipe 5, in the positive direction of the evaporation end of the heat pipe 5 The outer surface (i.e. the sunny side) is coated with a heat-absorbing coating 17, and two narrow strip photovoltaic panels 7 are pasted on the aluminum plate 16 and are respectively located on both sides of the heat pipe 5, and the aluminum plate 16 is connected with the U-shaped copper pipe 6 and the heat pipe 5. Paste it with heat-conducting glue; place the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com