Vision measuring method of crankshaft crank eccentricity and device thereof

A visual measurement and crankshaft technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of surface damage of crankshaft parts, unqualified crankshaft products, and long measurement process, so as to achieve system stability, improve production efficiency, reduce The effect of human resources spending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

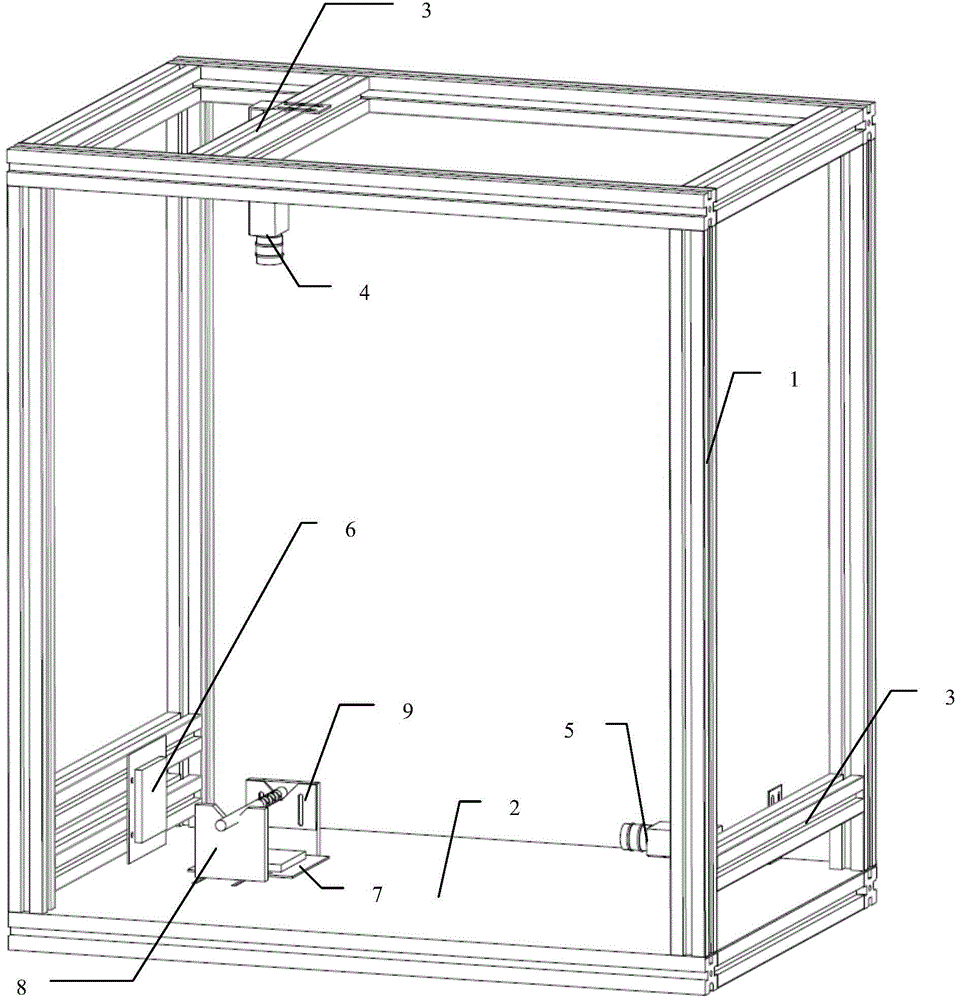

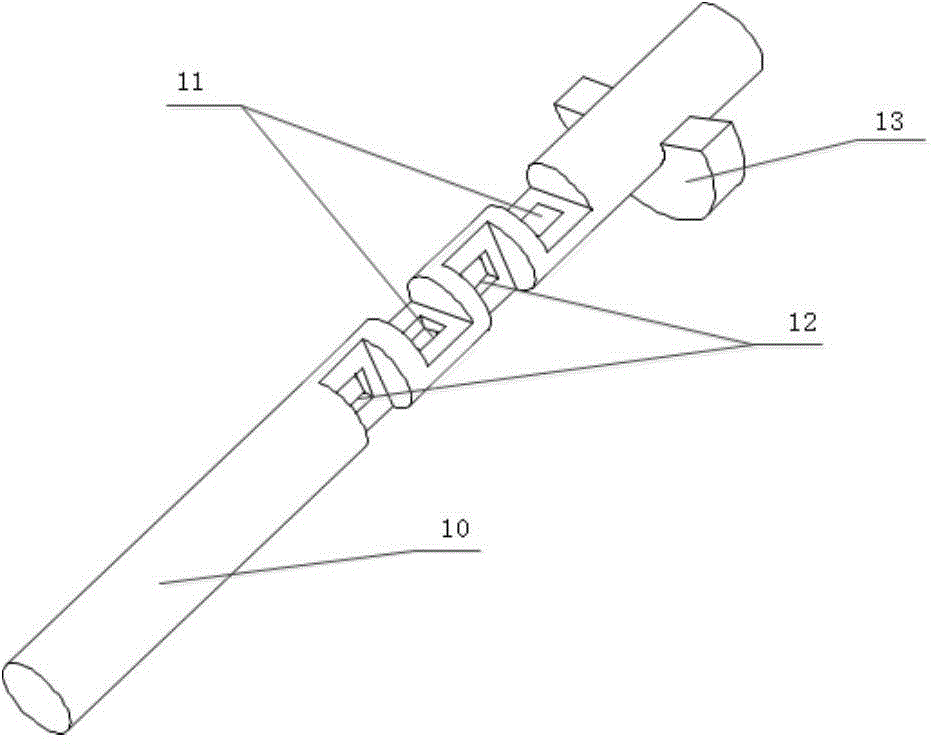

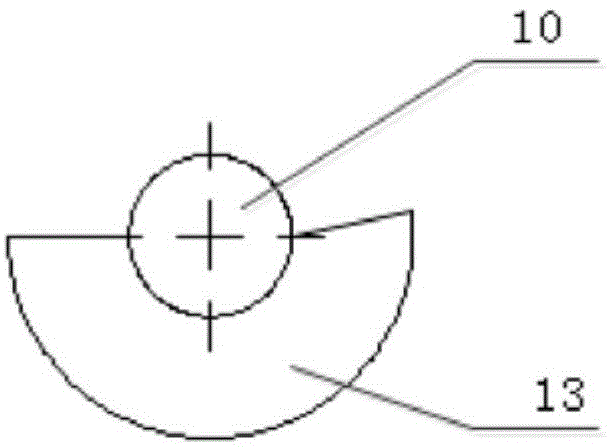

[0052] refer to figure 1 , in order to facilitate the measurement of the eccentricity of the crankshaft crank, the preferred embodiment of the present invention firstly provides a visual measuring device for the eccentricity of the crankshaft crank, comprising a cuboid frame 1 composed of aluminum profiles, the bottom of the frame 1 is provided with a bottom plate 2, and the frame 1 The upper side and the right side are respectively provided with a vertical camera 4 and a horizontal camera 5 fixed on the camera mounting plate 3, a vertically installed light source 6 is provided at the bottom of the left side of the rack 1 corresponding to the position of the horizontal camera 5, and the top of the bottom plate 2 The position corresponding to the position of the vertical camera 4 is provided with a horizontally installed light source 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com