Airplane auxiliary fuel tank flutter model

A flutter model and auxiliary fuel tank technology, which is applied in the field of aviation testing, can solve the problems of inconvenient stiffness adjustment, difficult coupling of pitch and yaw modes, and the influence of aircraft flutter characteristics is not considered, so as to achieve the effect of saving test costs and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

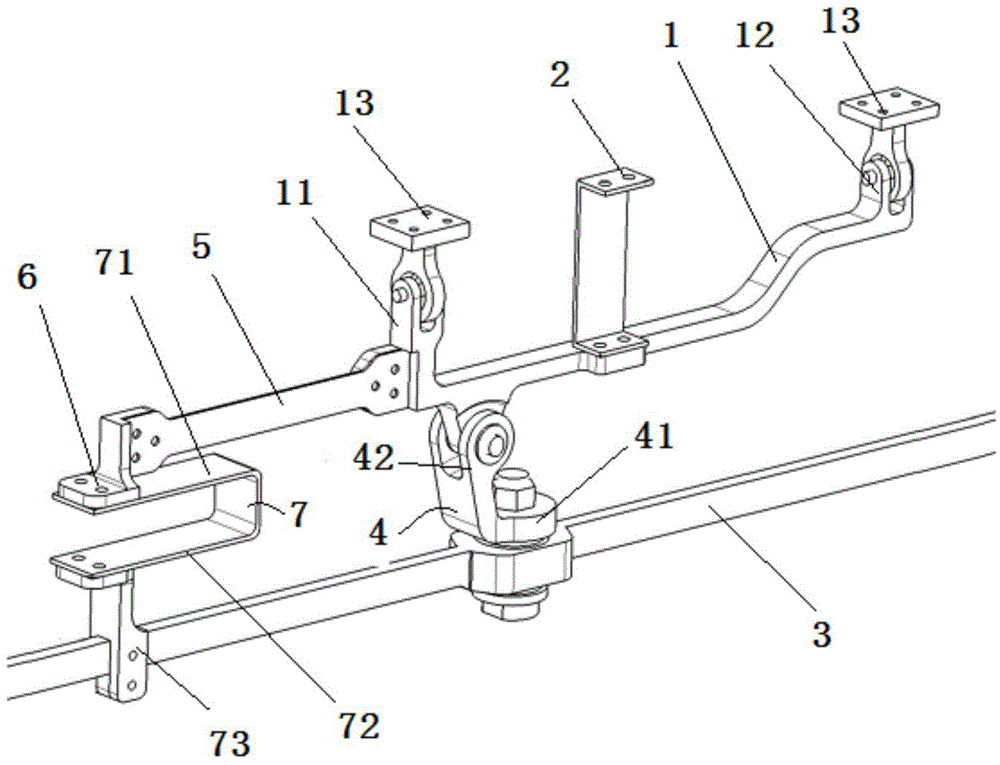

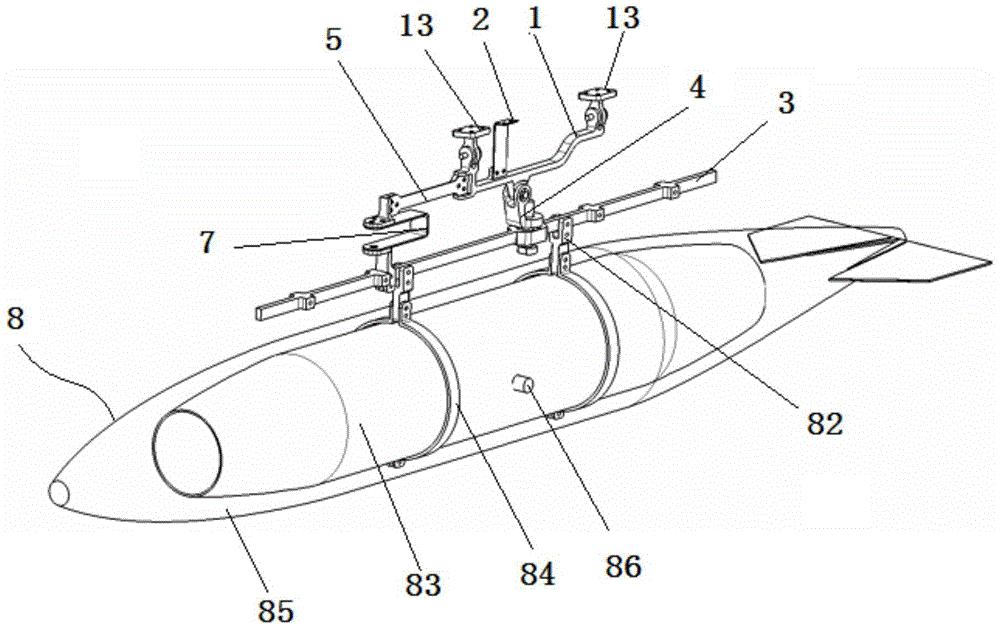

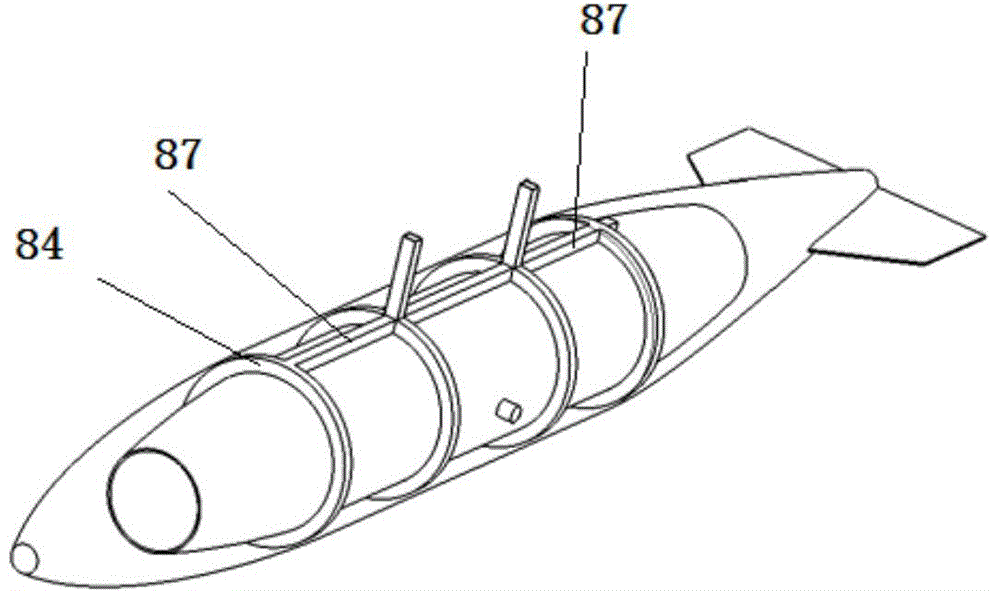

[0028] Such as figure 1 and figure 2 As shown, the aircraft auxiliary fuel tank flutter model provided by the present invention includes a general pylon beam 1, a special pylon beam 3, an auxiliary fuel tank model 8, and a side flat spring plate 2, a rotating arm 4, and a yaw spring arranged between them Sheet 5 and pitch spring sheet 7 and other components.

[0029] The universal hanger beam 1 can adopt various suitable structures, and has protruding first fixing parts 11 and second fixing parts 12 at the top surfaces of both ends of the universal hanger beam 1 along the direction perpendicular to the axis of the universal hanger beam 1 . Wherein, one end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com