Board-Level Integrated Magnetic Inductive Sensor Based on Surface Acoustic Wave Resonator

A technology of magnetic induction sensor and surface acoustic wave, applied in instruments, measuring magnetic variables, the size/direction of magnetic field, etc., can solve the problems of inconvenient digital acquisition and processing of output signals, and achieve convenient digital acquisition and processing, flexible frequency adjustment, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

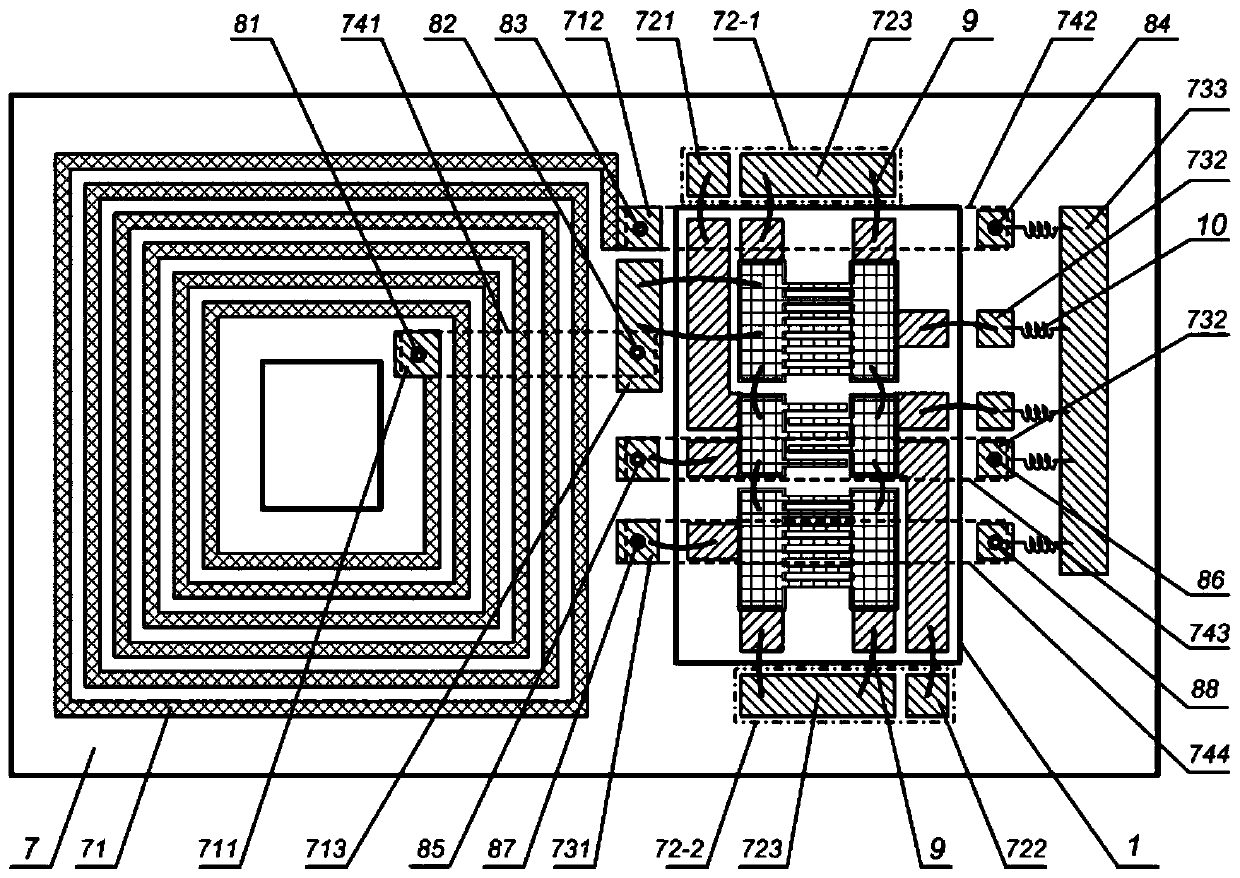

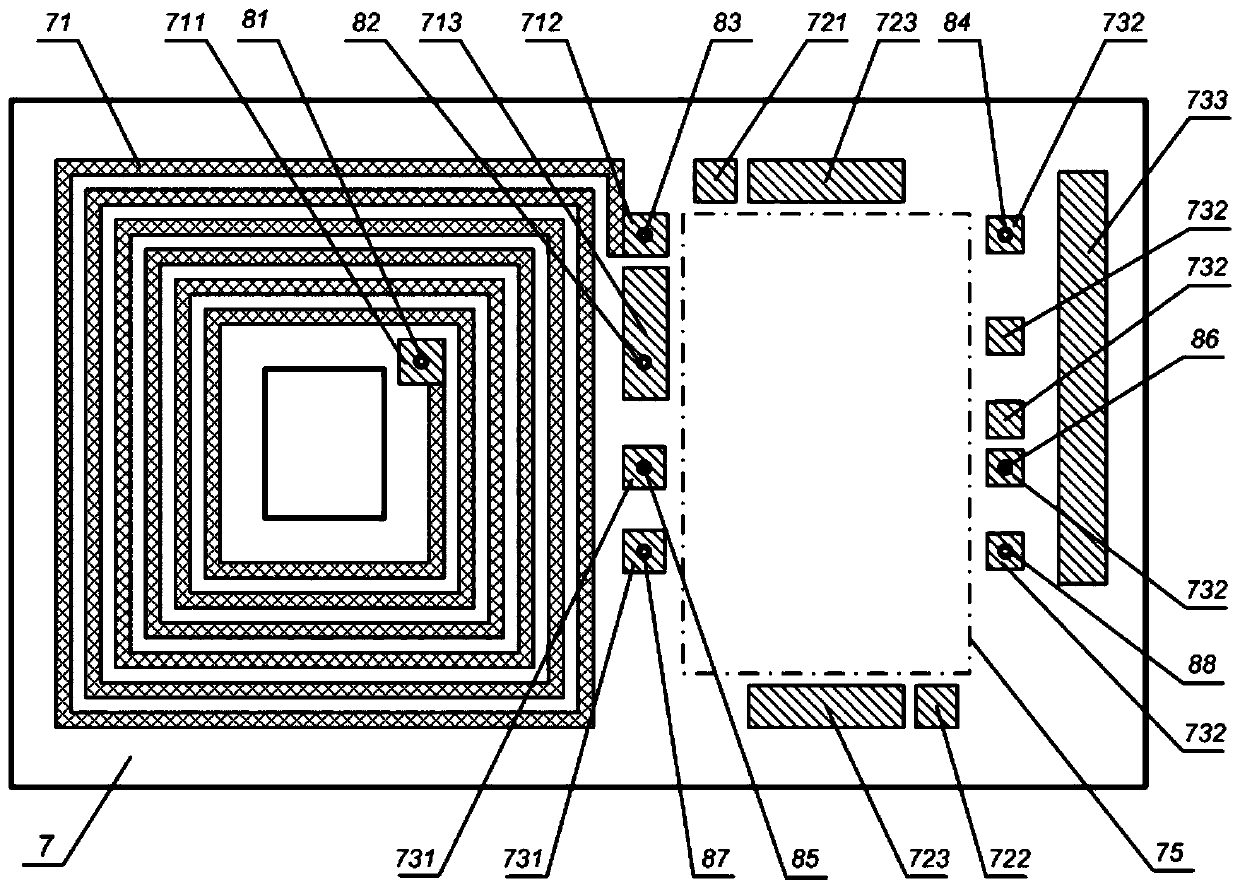

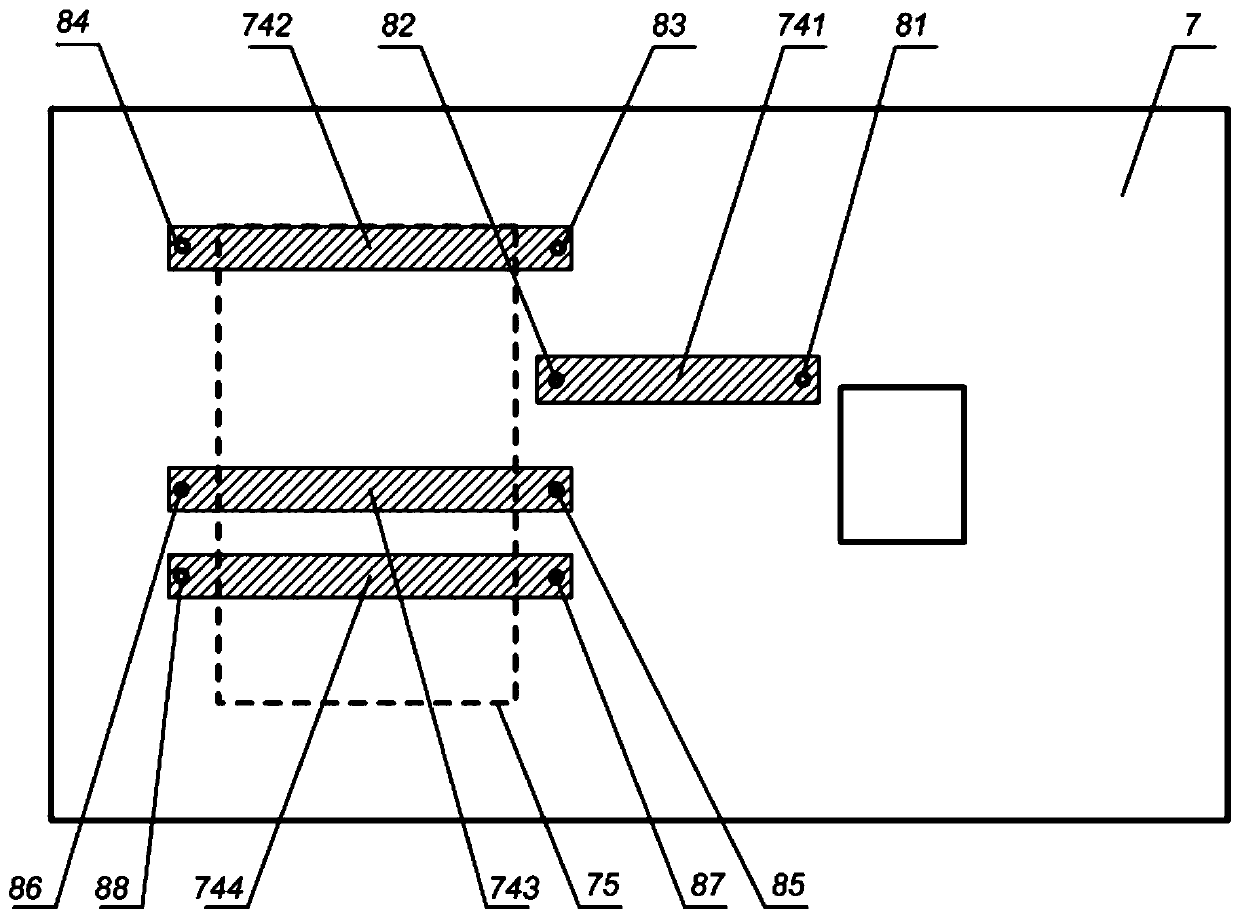

[0027] Such as figure 1 As shown, the board-level integrated magnetic induction sensor based on the surface acoustic wave resonator of the present invention includes a high-frequency substrate 7, a surface acoustic wave resonator chip attached to the chip bonding area 75 on the top side of the high-frequency substrate 7, and The planar magnetic induction coil 71 etched on the other side of the top surface of the high-frequency substrate 7 also includes a plurality of metal film wires etched on the bottom surface of the high-frequency substrate 7; the inner and outer ends of the planar magnetic induction coil 71 pass through Metal film wires, metal through holes, DC electrodes and bonding wires 9 are respectively connected to the voltage regulation electrode layer of the surface acoustic wave resonator and the DC ground electrode on the high frequency substrate 7 .

[0028] That is to say, the two ends of the metal film wire are respectively connected to the chip electrode of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com