Straightening method based on support vector machine for workpiece deformation

A support vector machine and workpiece technology, applied in the field of workpiece correction, can solve problems affecting the accuracy of deformation correction, difficult to do, lack of learning, etc., to achieve remote operation monitoring, save test funds and time, and improve efficiency and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

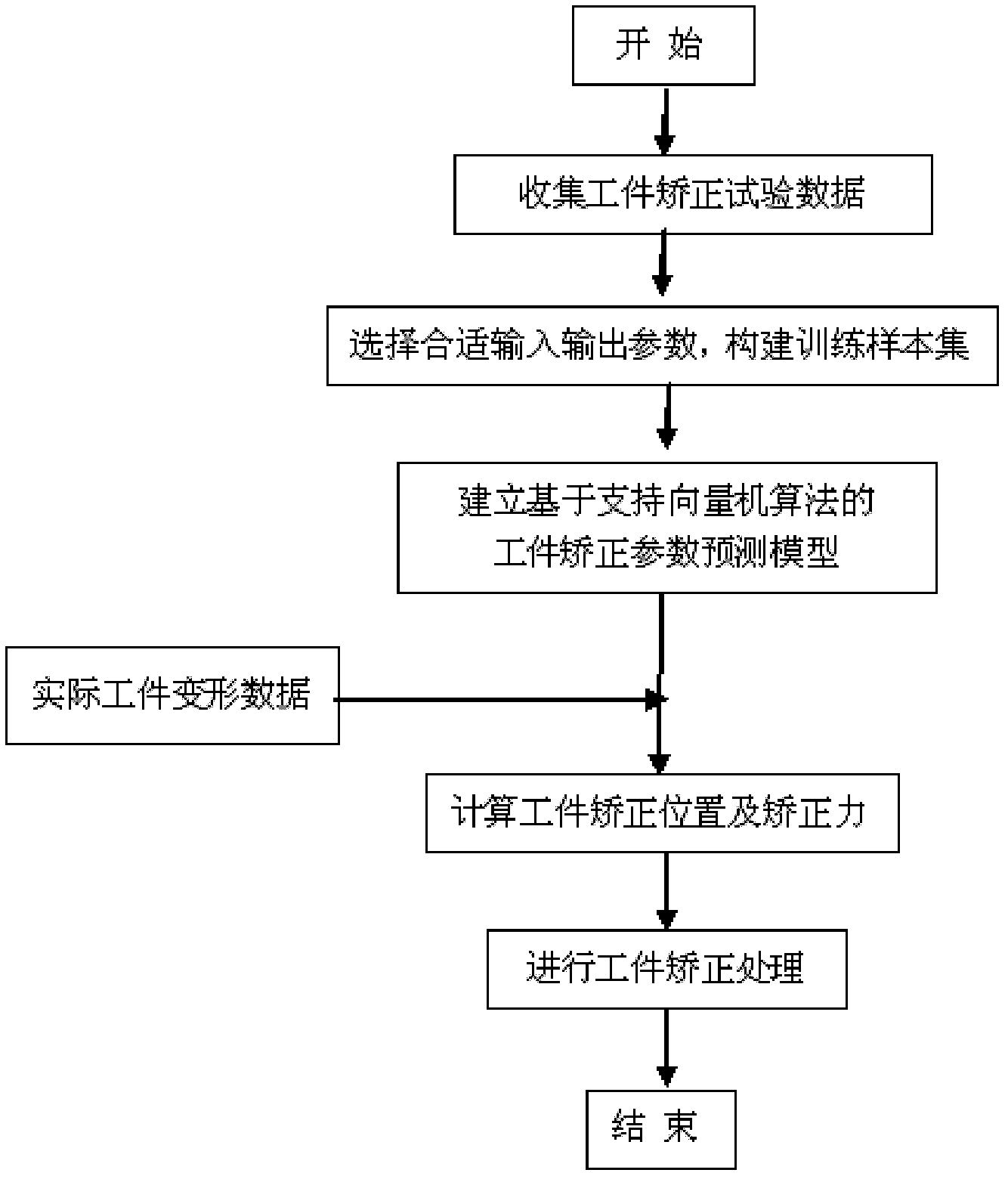

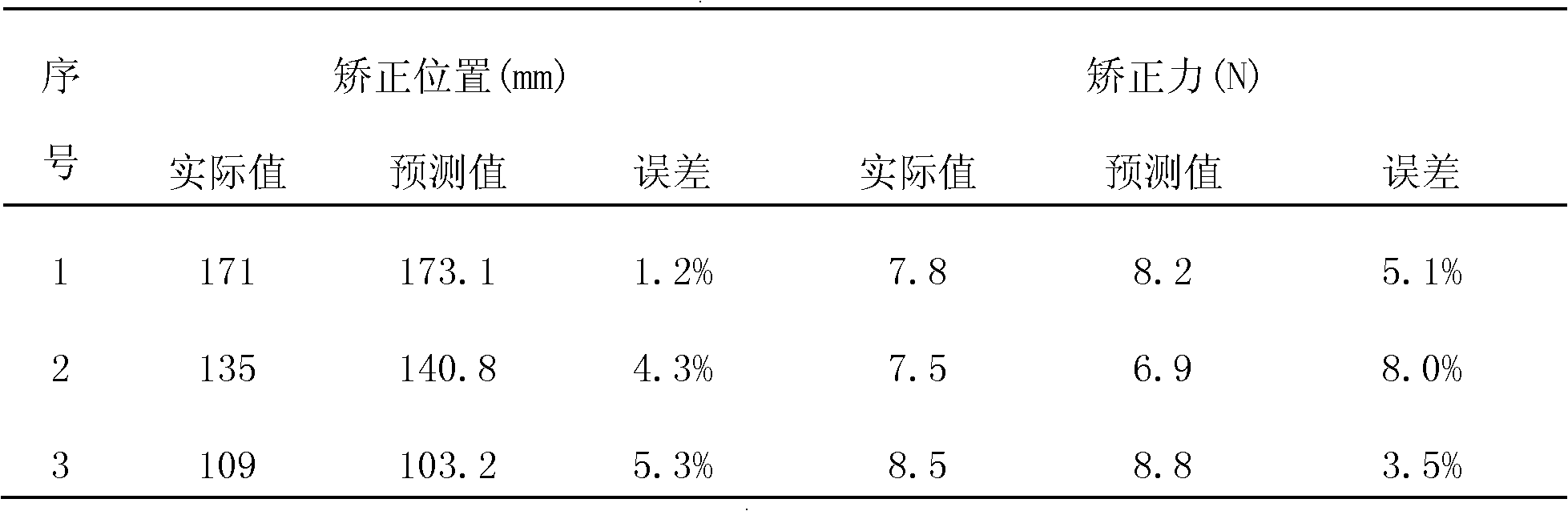

[0017] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail. figure 1 It is a specific flow chart of the workpiece intelligent correction method based on the support vector machine algorithm of the present invention. The present invention includes the following steps:

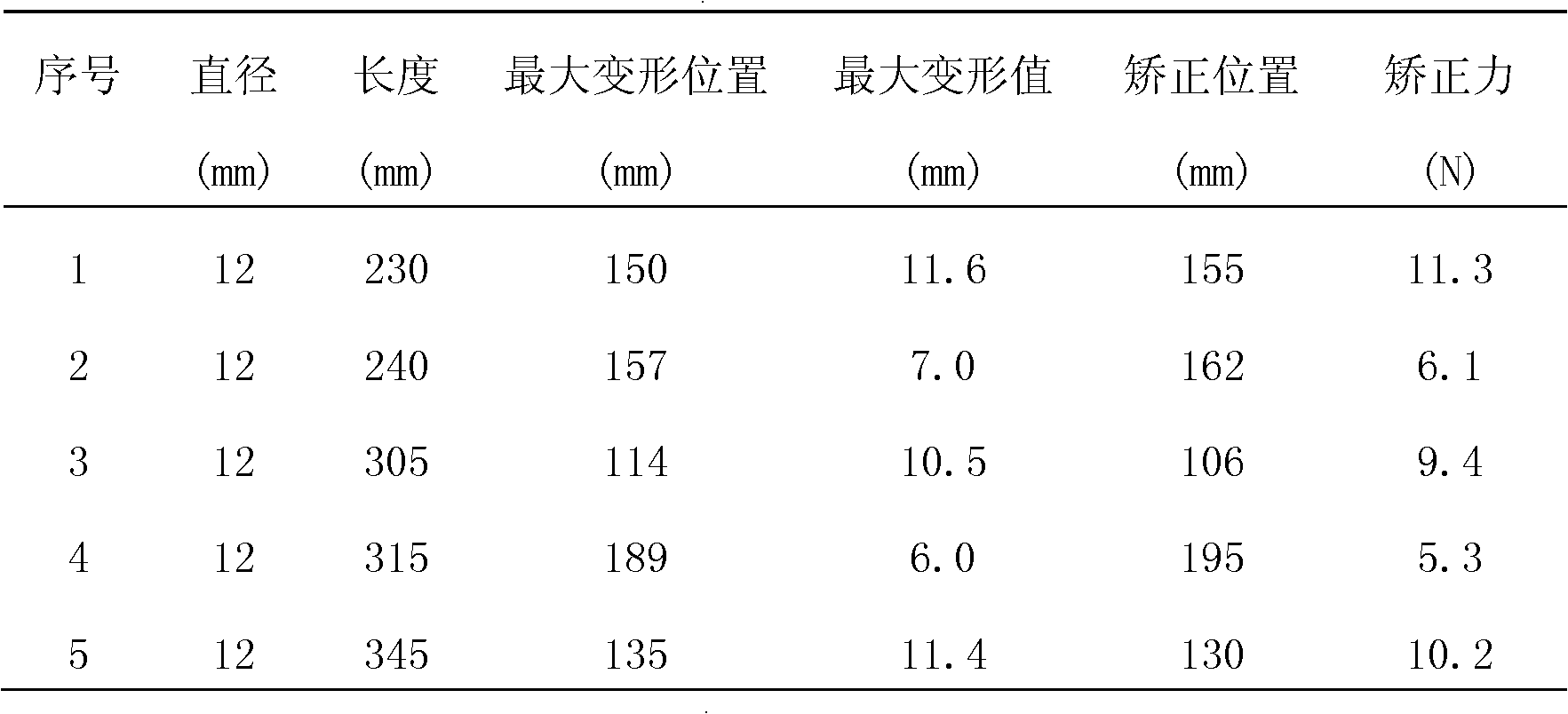

[0018] (1). Collect work piece deformation correction data: Carry out work piece correction tests under different materials, different sizes, different deformation positions, and different degrees of deformation, and collect correction force position and size data. If the conditions are not met, past experience data can be collected.

[0019] (2). Create a training sample set

[0020] Sort out the workpiece deformation correction test data obtained in step 1, and construct a training sample set. The input parameters include workpiece material parameters, shape dimensions, deformation position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com