Photomask detection structure and detection method thereof

A detection structure and detection method technology, applied in the semiconductor field, can solve the problems of not being detected, the risk of detection results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The detection method of the photomask of the present invention will be further described below in conjunction with the accompanying drawings. In this embodiment, the phase shift photomask is used as an example for illustration, but it should be noted that this embodiment is only for illustrative purposes. The above method is not limited to the phase shift mask, and can also be applied to a type of mask in which the chrome crystal ring pattern is set as a non-detection area.

[0055] The method of the present invention comprises:

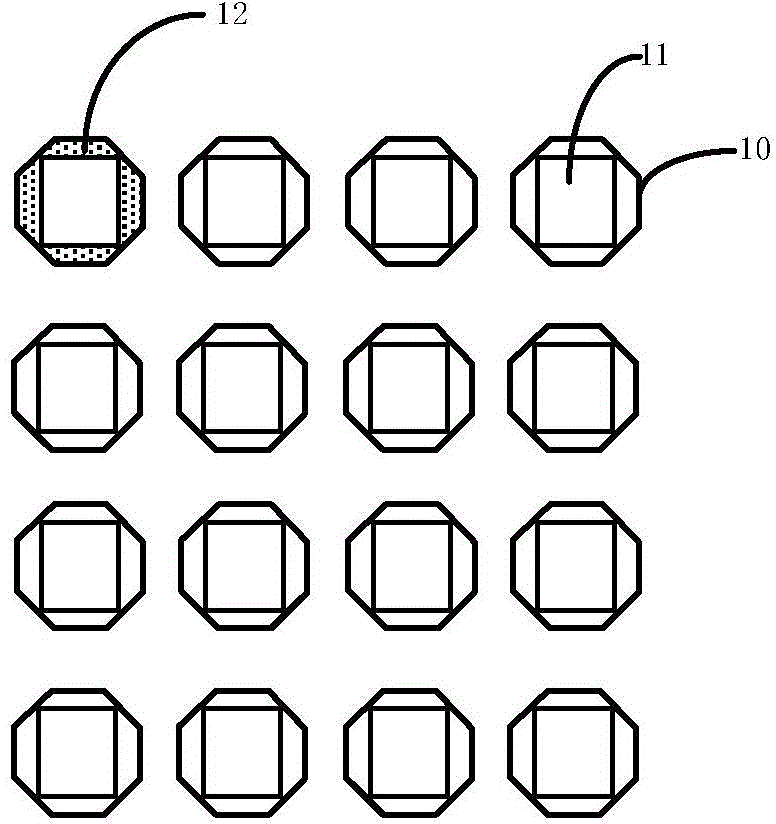

[0056] Step (a) providing a phase shift mask, the phase shifter has a chromium crystal ring array composed of mutually isolated chromium crystal rings 20;

[0057] Step (b) Determine the scope of the inspection area 21 in the phase shift mask, so that the outermost horizontal frame and vertical frame in the chrome crystal ring array are set outside the inspection area 21, set to non- inspection area;

[0058] Step (c) setting a first non-ins...

Embodiment 2

[0084] The present invention also provides a detection structure of a phase shift mask, including:

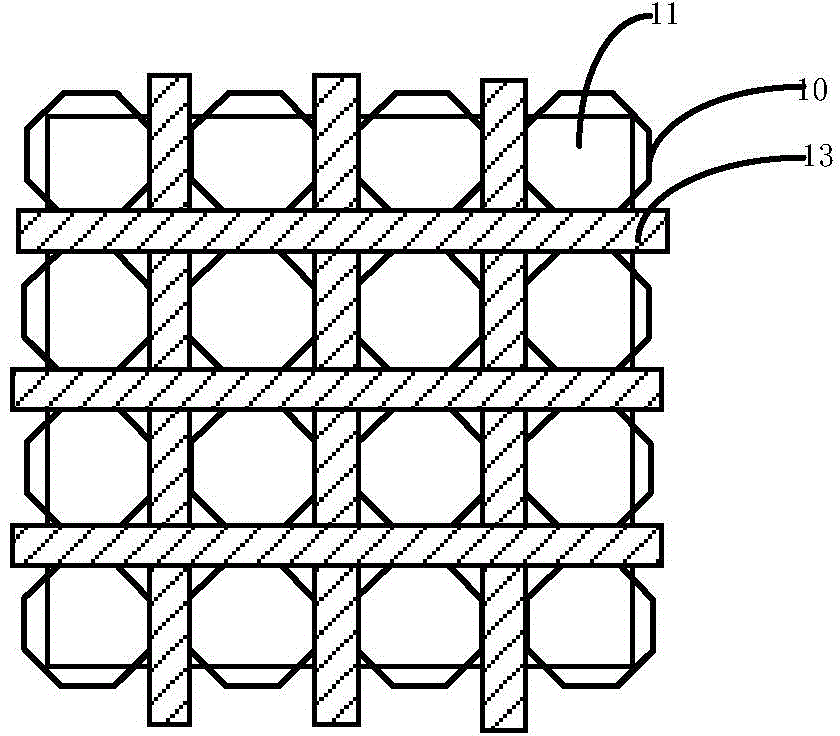

[0085] The array of chrome crystal rings, located in the phase shift mask, includes mutually isolated chrome crystal rings 20;

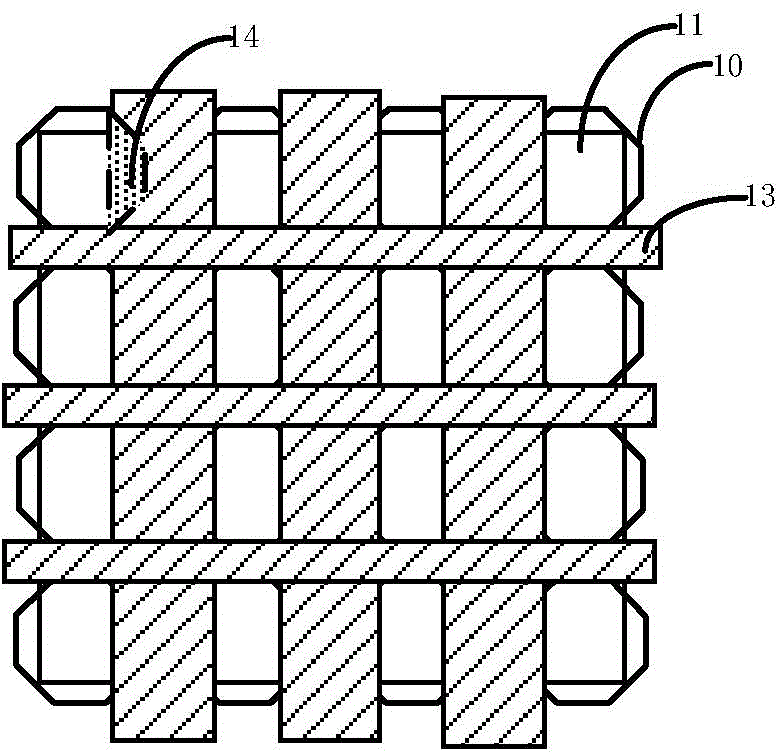

[0086] The inspection area 21 is located in the phase shift mask, so that the outermost horizontal frame and vertical frame in the chrome crystal ring array are set outside the inspection area 21 and set as a non-inspection area;

[0087] The first non-inspection area array 22 is located in the phase shift mask and covers the horizontal frame and the vertical frame of the chromium crystal ring inside the chrome crystal ring array to form a non-inspection area;

[0088] The second non-inspection area array 23 is located in the inspection area 21 and covers the hypotenuse frame inside the chromium ring array to form a non-inspection area.

[0089]Wherein, the detection structure further includes a third non-inspection area array 24, which is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com