Method and container for verifying whether all fragments of a broken needle are present

A technology of containers and fragments, which is applied in the application field of containers in vehicles, can solve the problems of not obtaining and not being able to continue working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

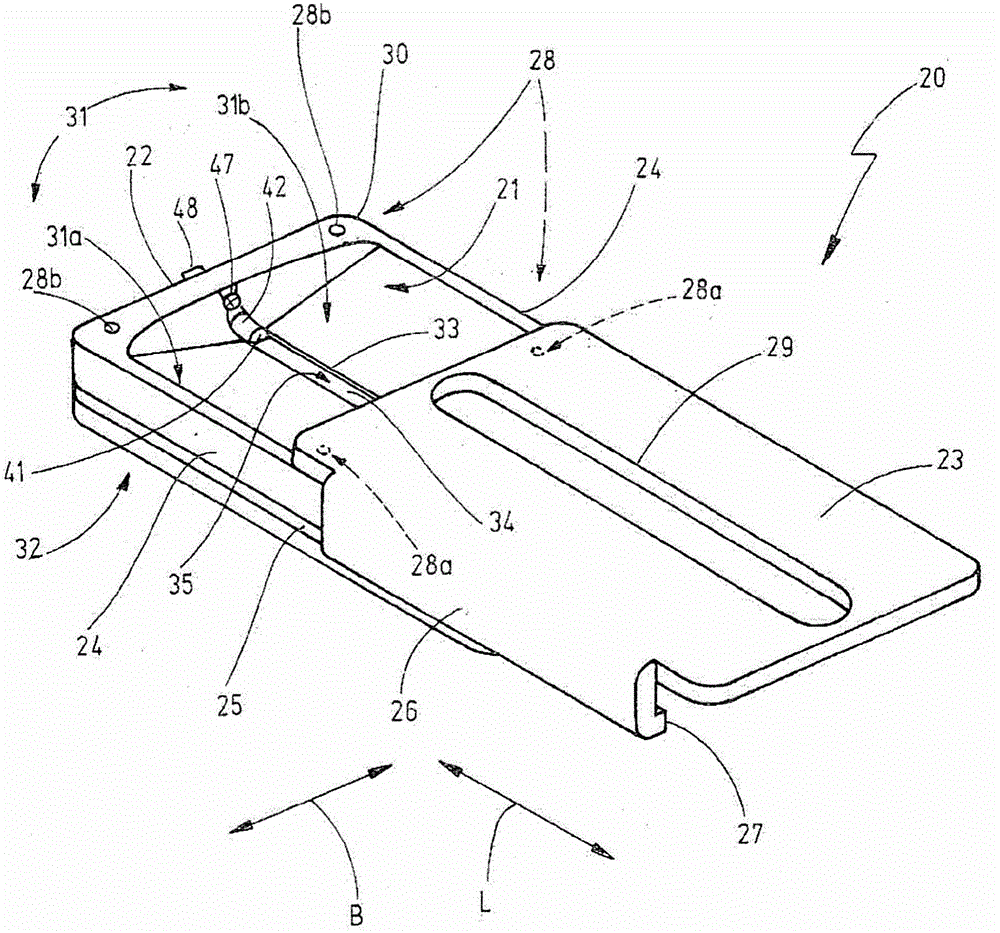

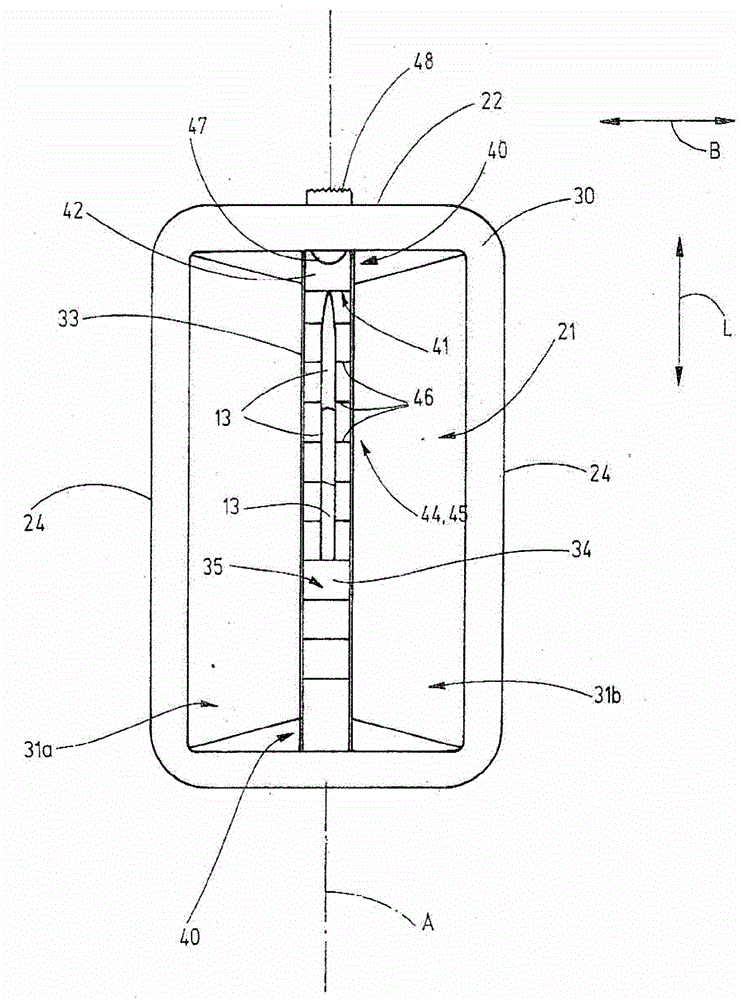

[0079] exist Figure 4 The sequence of a method 10 for quality assurance when sewing textile items, such as textile garments, is schematically illustrated in . The textile part is produced in several work stations 11 . For this purpose, the textile workpieces are transferred from one station 11 to the next station 11 in a predetermined sequence. The sewing process is only terminated when the textile workpiece has passed all stations 11 . In each station 11 the sewing process is carried out on the textile workpiece until finally the sewing work on the textile piece is ended after passing through all the stations.

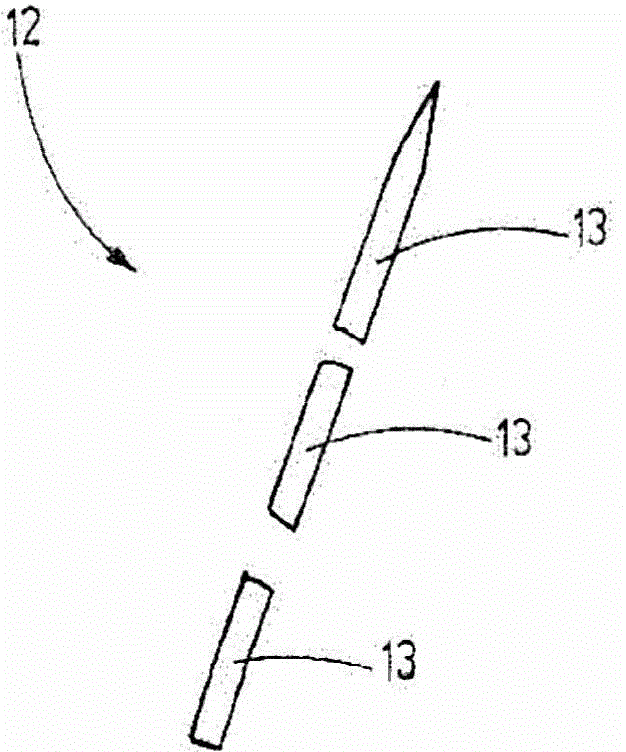

[0080] Each station 11 has a sewing machine (Naehemaschine). Furthermore, a needle port (Nadel pass) for the currently used sewing needle is located on each sewing machine. In station 11 there is no replacement sewing needle. To ensure that when worn, the replacement sewing needle 12a is not simply used when the needle 12 is damaged or broken and continues to wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com