Grain combine harvester

A combine harvester, grain technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of heavy chopping load, easy blockage, long fuselage, etc., to reduce the chopping load and prevent blockage , to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

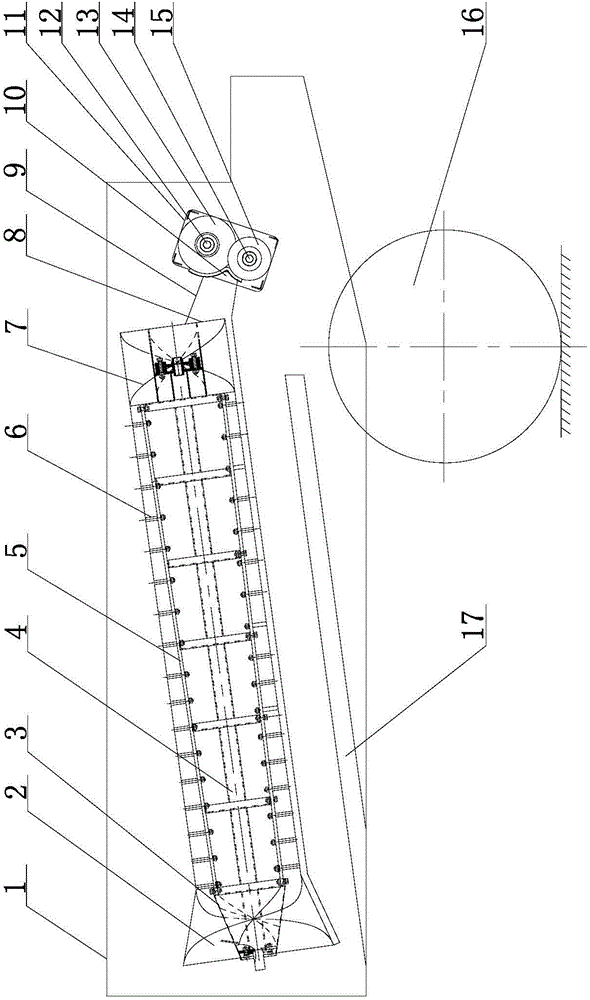

[0015] Such as figure 1 As shown, the grain combine harvester includes a casing 1, a threshing drum, a cleaning screen 17, a straw chopping device, a rear steering wheel 16 and other working parts. The threshing drum includes a feeding cone 3, a threshing drum 5 and the drum shaft 4, the feeding conical cylinder 3 is arranged on the front end of the threshing cylinder 5, the feeding auger blade 2 is installed on the feeding conical cylinder 3, and the rear end of the threshing cylinder 5 is equipped with blades in the shape of Spiral grass discharge auger 7, threshing nail teeth 6 are installed on the circumference of the threshing drum cylinder 5, the front end rotation diameter of the feeding auger blade 2 is larger than the rear end rotation diameter and the front end rotation diameter is conveyed by the header of the harvester. The width of the bridge coinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com