Gas-liquid distributor for wood tar ebullating bed reactor

A technology of ebullating bed reactors and gas-liquid distributors, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high probability of catalyst reverse flow, affecting the return sealing effect, and large bounce of check balls, etc., to achieve The gas-liquid diffusion area is wide, the use is safe and reliable, and the effect of expanding the diameter of the bubble flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The gas-liquid distributor for wood tar ebullating bed reactor of the present invention will be further described below in conjunction with the accompanying drawings.

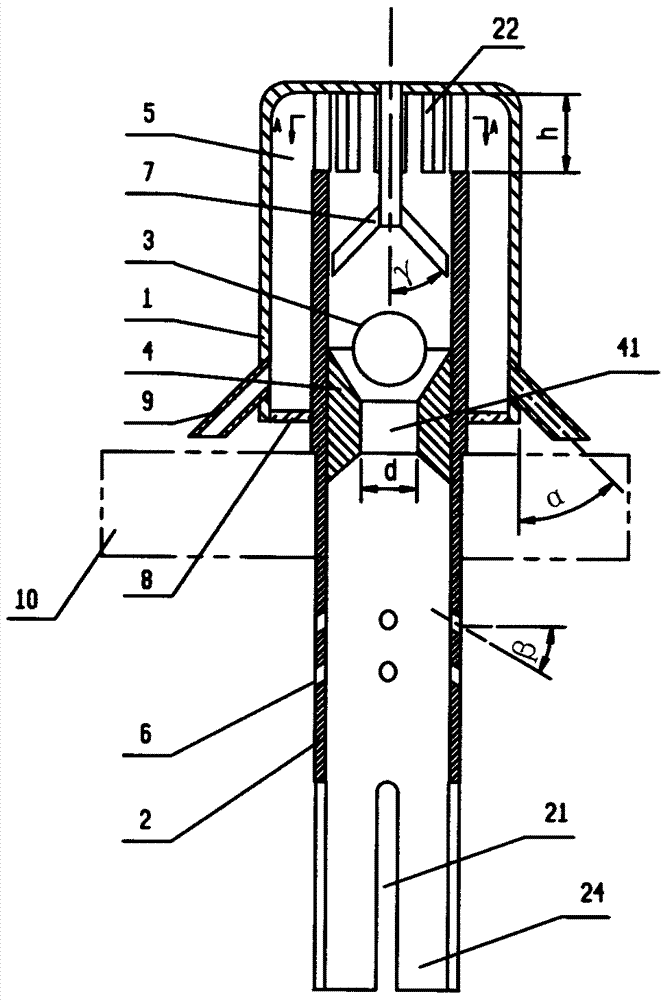

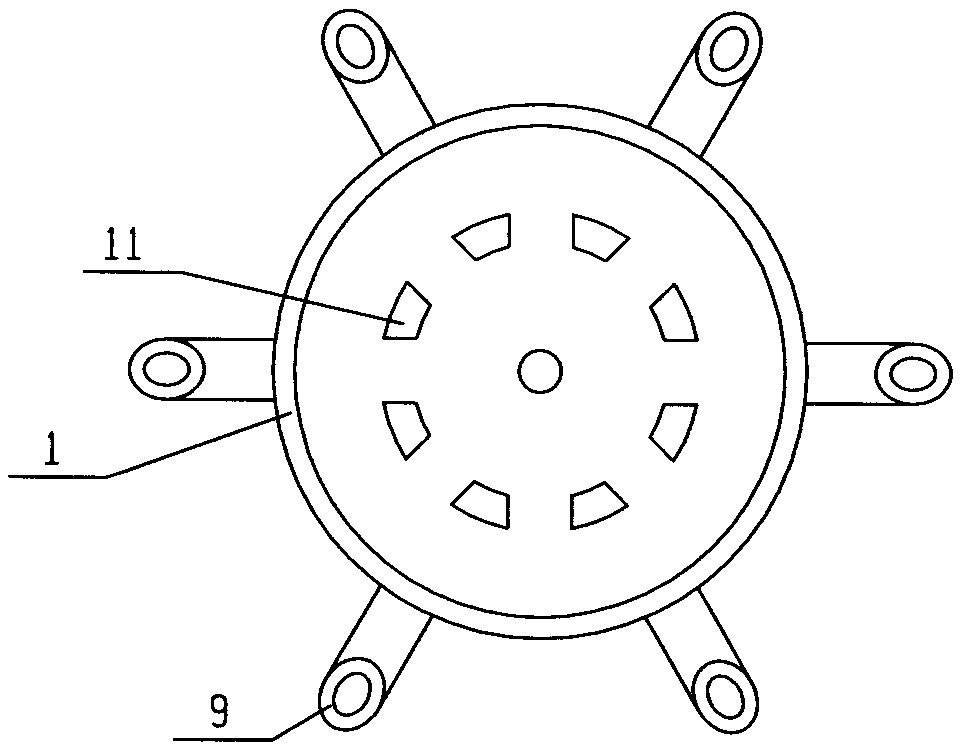

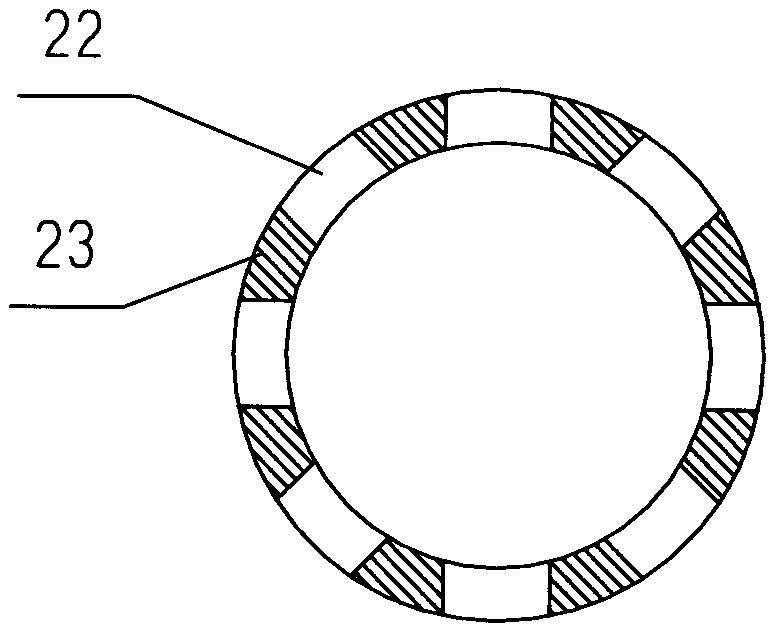

[0028] Such as figure 1 As shown, the gas-liquid distributor for wood tar ebullated bed reactor provided by the present invention is mainly composed of central tube 2, bubble cap 1, non-return ball 3, conical ball seat 4 and limit seat 7; bubble cap 1 It is a cylinder with an open bottom, covered on the upper end of the central tube 2 and fixedly connected with the central tube 2, the tube wall at the upper end of the central tube 2 is provided with a longitudinal slot 22 as a material outlet, and the limit seat 7 is set In the central tube below the longitudinal slot 22, the conical ball seat 4 is arranged on the central tube wall below the limit seat 7, and the conical ball seat 4 is provided with a non-return ball 3, a bubble cap 1, a central tube 2, The limit seat 7, the non-return ball 3 and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com