Steel bar bender

A steel bar bending and steel bar technology, applied in the field of steel bar processing equipment, can solve problems such as low efficiency, poor consistency, and large labor consumption, and achieve the effects of improving processing efficiency, avoiding manual reversal, and reducing preprocessing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

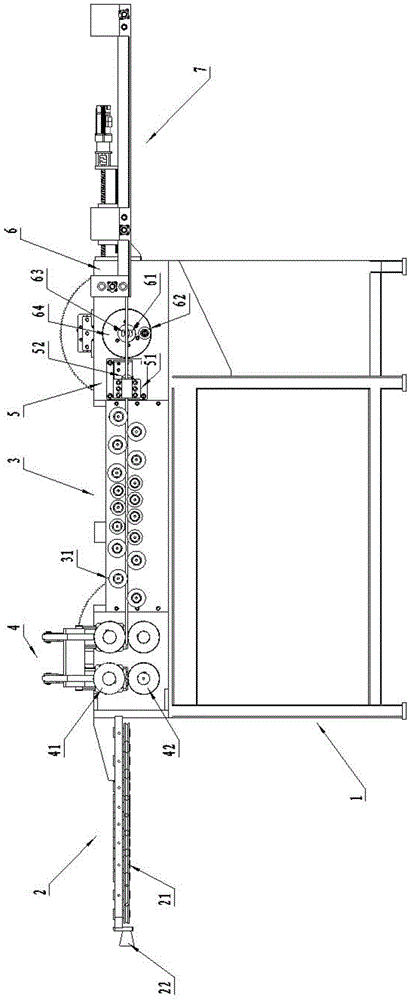

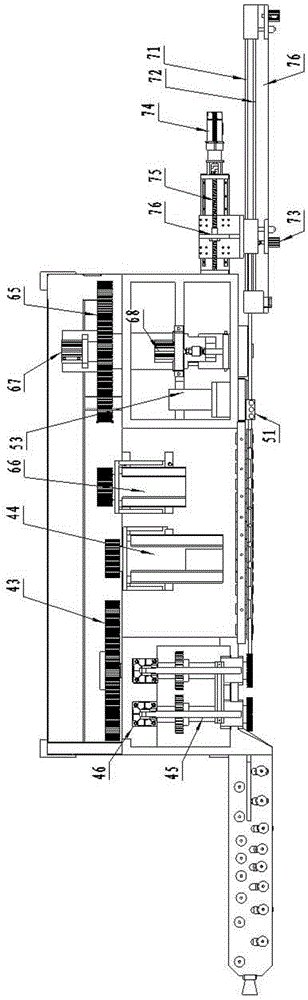

[0025] Such as figure 1 and figure 2 As shown, the steel bar bending machine of the embodiment of the present invention includes: including:

[0026] Machine 1: has a three-dimensional frame, which is used as the bottom support of the equipment;

[0027] The first straightening wheel set 2: there are two rows of first straightening wheels 21 arranged along both sides of the advancing line of the reinforcing bar, which are used to straighten the reinforcing bar once;

[0028] The second straightening wheel set 3: it is perpendicular to the axis of the first straightening wheel set 2 along the advancing line of the reinforcing bar, and has the second straightening wheels 31 arranged on both sides of the advancing line of the reinforcing bar for secondary adjustment of the reinforcing bar straight;

[0029] Traction pinch wheel set 4: It has pinch wheels arranged along both sides of the forward line of the steel bar, a pinch mechanism that drives the pinch wheel to press the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com