Hub outer cover of minicar

A technology of car and wheel hub, which is applied in the field of wheel hub outer cover of miniature cars, can solve the problems of outer cover breakage and low safety performance, and achieve the effects of clear ratio, reasonable method and high product hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

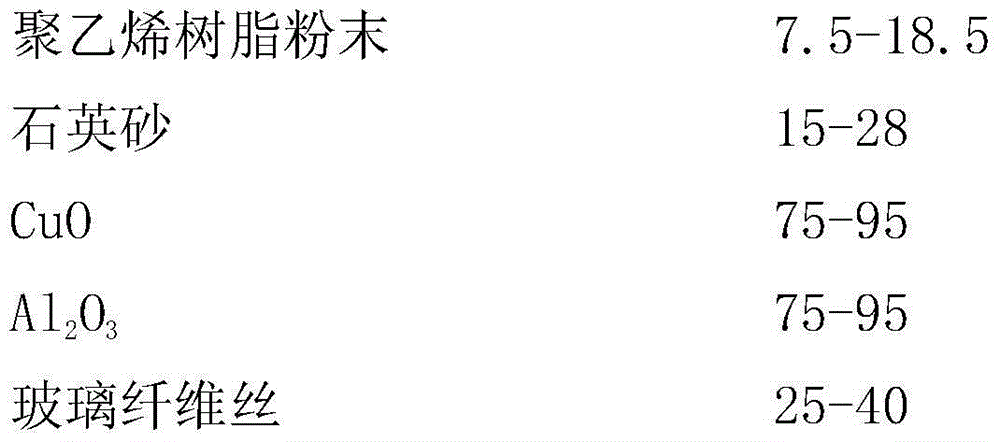

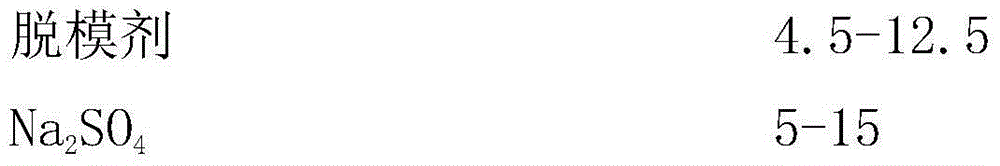

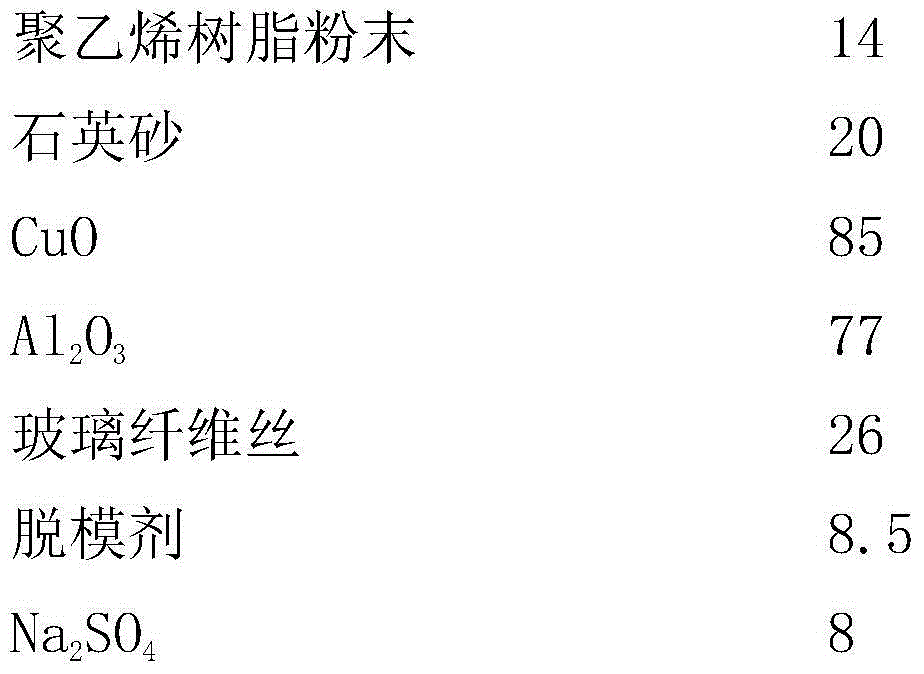

[0018] A wheel hub cover of a miniature car is characterized in that: the distribution ratio of each component is calculated as follows in weight fraction,

[0019]

[0020] A preparation method for a wheel hub cover of a miniature car comprises,

[0021] Ⅰ Make different styles of molds and runners according to the needs through paraffin, and then add CuO and Al 2 o 3 melt into a liquid;

[0022] Ⅱ Place the paraffin in the sprue, coat a layer of internal release agent on the surface of the paraffin, and then wrap a layer of quartz sand;

[0023] ⅢPour CuO liquid and Al into the sprue immediately after the completion of Ⅱ 2 o 3 Liquid, mixed molding;

[0024] ⅣPut the molded material into the baking machine and bake. When the paraffin wax melts, pour the polyethylene resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com