Variable-thickness automobile front bumper and manufacturing method thereof

The technology of front bumper and one front insurance is applied to the front bumper of a variable thickness automobile and its manufacturing field, and can solve the problems of non-uniform performance in the longitudinal direction of the front bumper, increasing the use cost of materials, wasting the usage of raw materials, and the like. Achieve the effect of meeting the body crash safety requirements, reducing the use of materials and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

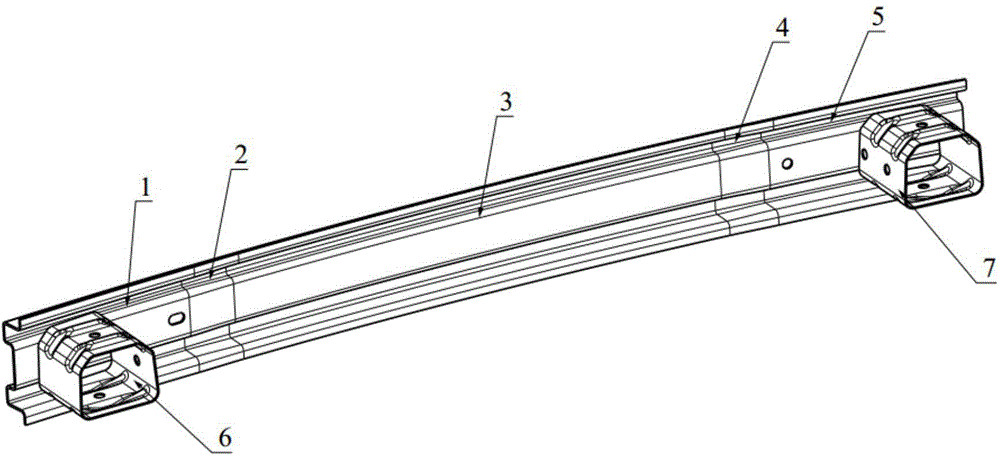

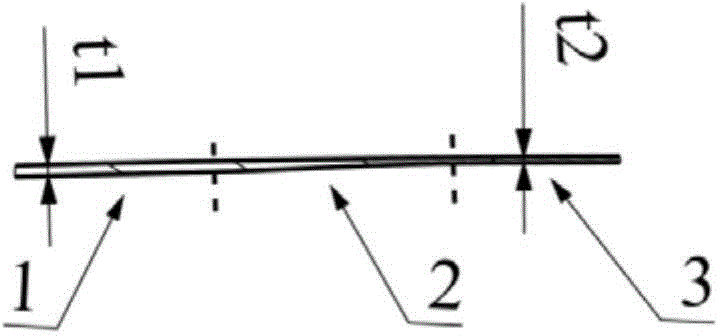

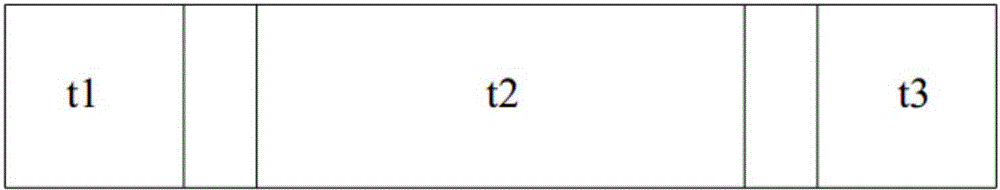

[0036] see figure 1 , a variable thickness automobile front bumper of the present invention, comprising, a front bumper body, which is a thin-walled structure, including a body left section 1, a left transition section 2, a body middle section 3, a right transition section 4, a body right Section 5; left and right energy-absorbing boxes 6, 7 are respectively arranged on the inner sides of the left and right sections 1, 5 of the front bumper body, and connect the front bumper body with the front longitudinal beam of the car; , the left and right sections 1 and 5 of the body are of equal thickness structure; the left and right transition sections 2 and 4 are of a continuously variable thickness structure, and the thickness of the left and right transition sections 2 and 4 is from the thick area at both ends to the middle section of the body 3 gradually decreases; the middle section 3 of the body is of equal thickness structure, and its thickness is the thinnest in the entire fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com