An Active Power Control System of Mountain Orchard Transporter

An active control system and control system technology, applied in transportation and packaging, brake transmission, brakes, etc., can solve the problems of lack of safety performance and power control can not be optimized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

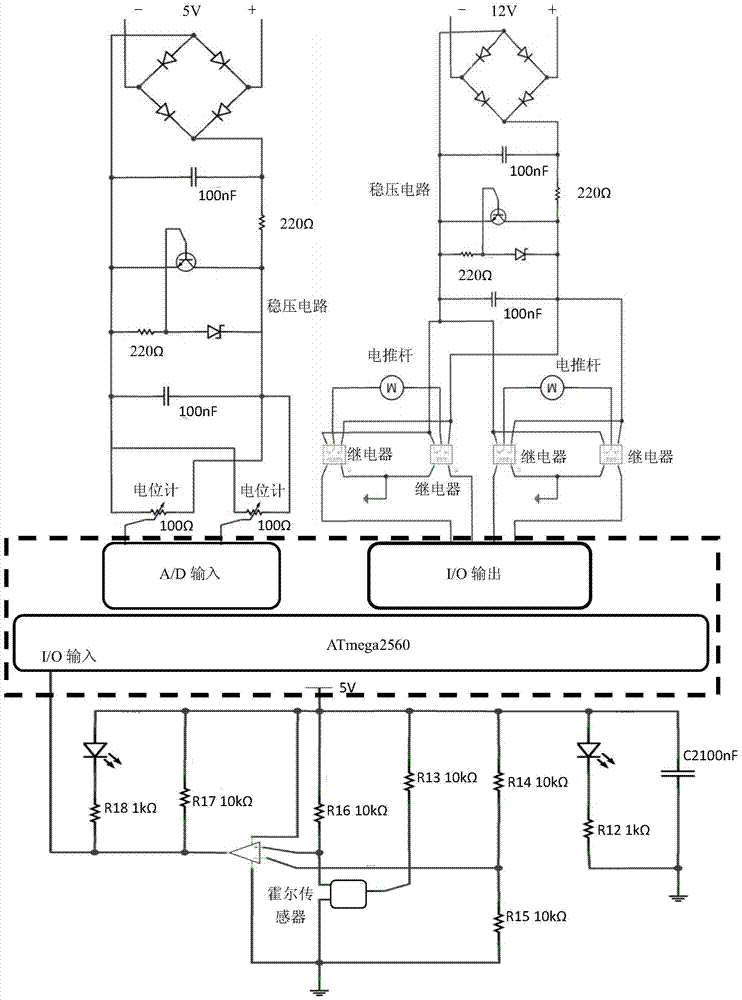

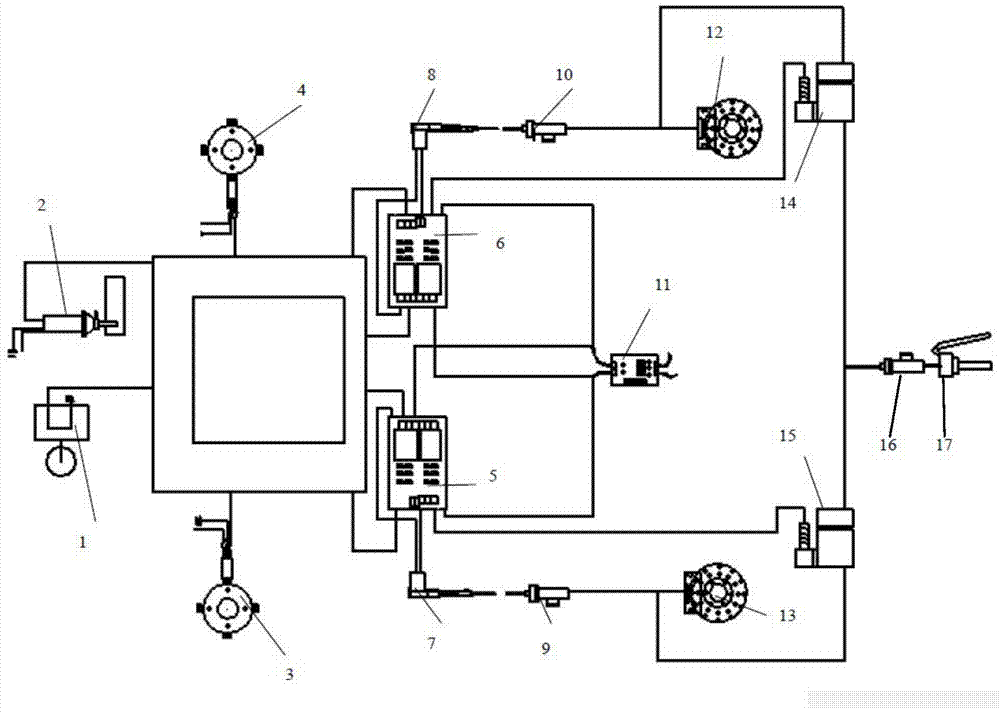

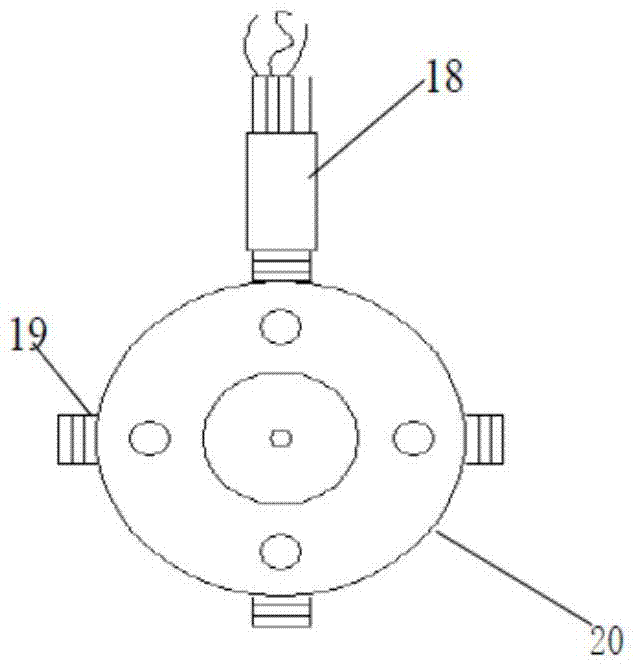

[0049] like figure 1 figure 2 As shown, the active power control system of mountain orchard transporter in this embodiment includes an MCU control system, and the input end of the MCU control system is connected with a steering angle detection module 1, a throttle opening detection module 2, and a first wheel speed detection module. 3 and the second wheel speed detection module 4, the output end of the MCU control system is respectively connected with the first relay 5 and the second relay 6, the first relay 5 is connected with the first electric push rod 7, and the first electric push rod 7. Connect to the first brake oil pump 9, the first brake oil pump 9 is connected to the first brake module 13, the first brake module 13 is connected to the first solenoid valve 15, and the first solenoid valve 15 is connected to the first relay 5; The second relay 6 is connected to a second electric push rod 8, and the second electric push rod 8 is connected to a second brake oil pump 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com