Smart container and indirect logistics distribution method based on smart container

An intelligent container technology, applied in the field of logistics indirect distribution and intelligent container, can solve the problems of large lockers, occupying space, and reduced efficiency of logistics locker system, so as to improve space utilization, improve access efficiency, The effect of improving the logistics process level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0048] Smart container of the present invention, its preferred embodiment is:

[0049] The smart container includes a dense shuttle belt conveyor storage area in the direction of the top view, and the two sides of the dense shuttle belt conveyor storage area are respectively provided with a warehouse-out temporary storage area and a warehouse-in temporary storage area. The front of the temporary storage area and the storage temporary storage area are respectively provided with a storage exit and a storage entrance, and the front of the intensive shuttle belt conveyor storage area is successively provided with a roadway machine shuttle and a tally storage area;

[0050] The smart container includes an express pick-up port in the front view direction, a dense storage area is provided on the upper part of the express pick-up port, and a delivery port and an emergency port are respectively provided on both sides of the express pick-up port.

[0051]The smart container is provided ...

specific Embodiment

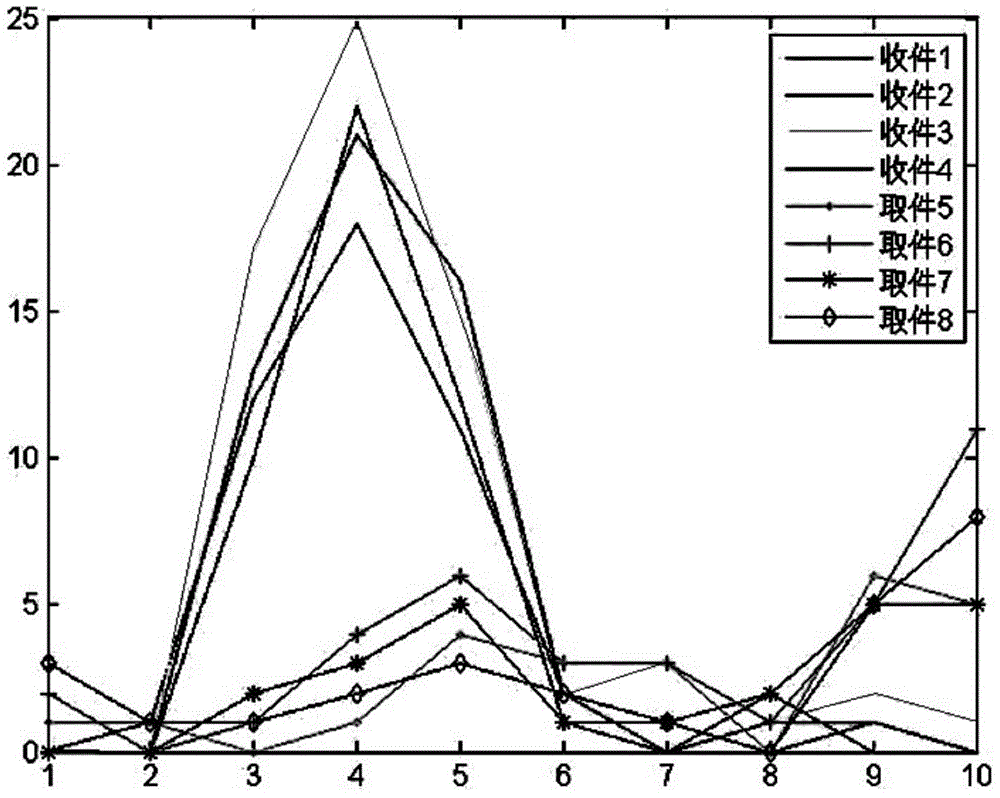

[0081] In order to improve the use efficiency of the logistics locker system, the optimization design is carried out from the following three aspects:

[0082] 1. Guarantee the express mail storage of those recipients who have a high awareness of extracting express mail, and reduce the express mail storage of those recipients who have a low awareness of extracting express mail;

[0083] 2. For the same time period, for multiple express shipments of the same recipient, try to store them in a combined manner;

[0084] 3. Improve the structure of the express box, or intelligently provide a storage box according to the volume of the express when storing the express.

[0085] 1. Storage process optimization:

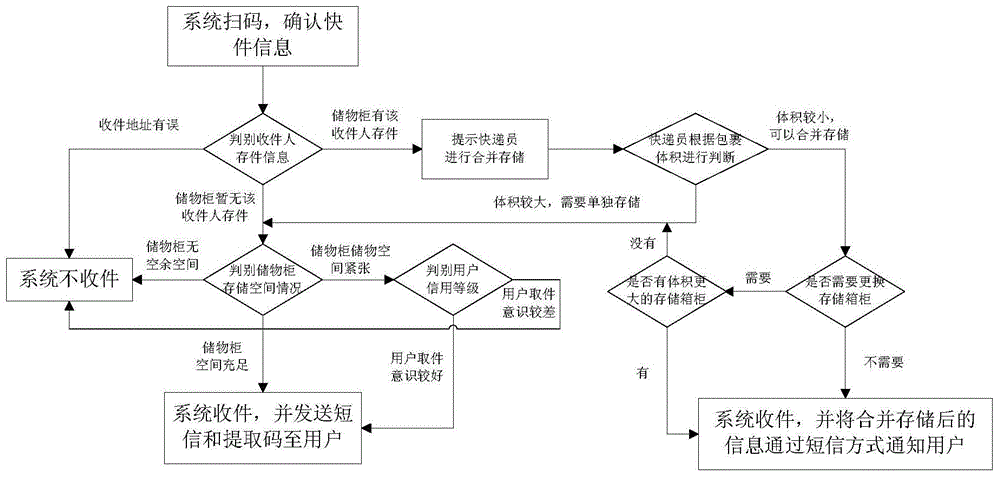

[0086] 1.1 Intelligent storage process

[0087] In order to realize the above three methods, the receiving process of the entire logistics storage cabinet system should be optimized first.

[0088] The optimized logistics storage cabinet system receiving process can be exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com