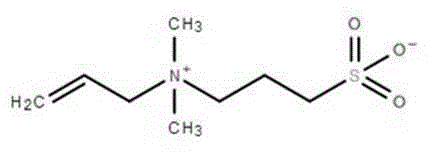

Preparation method of N,N-dimethylallyl propanesulfonate

A technology of dimethylallyl propane sulfonate and dimethyl allyl amine, which is applied in the field of preparation of N,N-dimethylallyl propane sulfonate, can solve the problems of temperature resistance and limitation Development and other issues, to achieve the effect of short reaction time, high product yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 430gDA and pour it into the reactor, then put it into a constant temperature water bath, heat and start stirring. Then weigh 122g PS, add it directly into DA, the reaction temperature is 45°C, stir and react for 3h to get the crude product of DAPS. Transfer the crude DAPS product to a large piece of filter paper, wrap it in a Soxhlet extractor, and use ethanol as a solvent to extract for 3 hours. After the extraction, put the filter paper bag in a drying box and dry it at 50°C to obtain Pure DAPS monomer with a yield of 92.6%. (The yield is the ratio of the mass of the product actually obtained to the mass of the theoretical product obtained by the stoichiometric reaction, the same below).

Embodiment 2

[0018] Weigh 680gDA and pour it into the reactor, then put it into a constant temperature water bath, heat and start stirring. Then weigh 122g PS, add it directly into DA, the reaction temperature is 55°C, stir and react for 3h to get the crude product of DAPS. Transfer the crude DAPS product to a large piece of filter paper, wrap it in a Soxhlet extractor, and use ethanol as a solvent to extract it for 2 hours. After the extraction, put the filter paper bag in a drying box and dry it at 50°C to obtain Pure DAPS monomer with a yield of 91.2%.

Embodiment 3

[0020] Weigh 460gDA and pour it into the reactor, then put it into a constant temperature water bath, heat and start stirring. Then weigh 122g PS, add it directly into DA, the reaction temperature is 40°C, stir and react for 2h to get the crude product of DAPS. Transfer the crude DAPS product to a large piece of filter paper and wrap it in a Soxhlet extractor. Use ethanol as the solvent to extract for 2.5 hours. The pure DAPS monomer was obtained with a yield of 92.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com