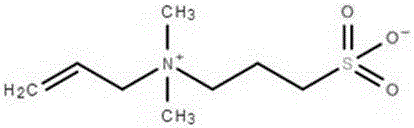

A kind of preparation method of n,n-dimethylallyl propane sulfonate

A technology of dimethylallyl propane sulfonate and dimethyl allyl amine is applied in the field of preparation of N,N-dimethylallyl propane sulfonate, which can solve the problems of temperature resistance and limitation Development and other issues, to achieve the effect of short reaction time, high product yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 430gDA and pour it into the reactor, then put it into a constant temperature water bath, heat and start stirring. Then weigh 122g PS, add it directly into DA, the reaction temperature is 45°C, stir and react for 3h to get the crude product of DAPS. Transfer the crude DAPS product to a large piece of filter paper, wrap it in a Soxhlet extractor, and use ethanol as a solvent to extract for 3 hours. After the extraction, put the filter paper bag in a drying box and dry it at 50°C to obtain Pure DAPS monomer with a yield of 92.6%. (The yield is the ratio of the mass of the product actually obtained to the mass of the theoretical product obtained by the stoichiometric reaction, the same below).

Embodiment 2

[0018] Weigh 680gDA and pour it into the reactor, then put it into a constant temperature water bath, heat and start stirring. Then weigh 122g PS, add it directly into DA, the reaction temperature is 55°C, stir and react for 3h to get the crude product of DAPS. Transfer the crude DAPS product to a large piece of filter paper, wrap it in a Soxhlet extractor, and use ethanol as a solvent to extract it for 2 hours. After the extraction, put the filter paper bag in a drying box and dry it at 50°C to obtain Pure DAPS monomer with a yield of 91.2%.

Embodiment 3

[0020] Weigh 460gDA and pour it into the reactor, then put it into a constant temperature water bath, heat and start stirring. Then weigh 122g PS, add it directly into DA, the reaction temperature is 40°C, stir and react for 2h to get the crude product of DAPS. Transfer the crude DAPS product to a large piece of filter paper and wrap it in a Soxhlet extractor. Use ethanol as the solvent to extract for 2.5 hours. The pure DAPS monomer was obtained with a yield of 92.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com