Composite nano mining cable sheath material and preparation method therefor

A cable sheath and mine-used technology, applied in the field of composite nano-mine cable sheath material and its preparation, can solve the problems of poor flame retardant effect, low tensile strength, low elongation at break, etc., and achieve improved flame retardant Performance and anti-aging performance, improvement of mechanical strength, effect of improvement of mechanical strength and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

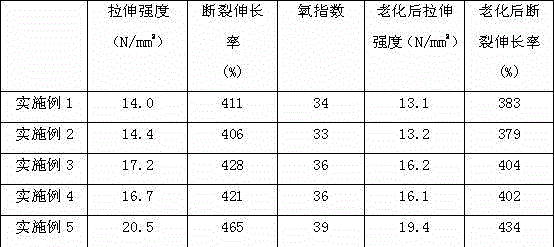

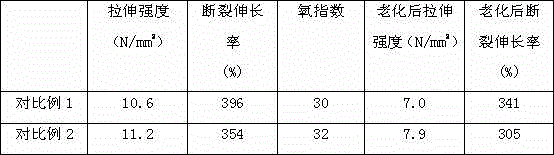

Examples

Embodiment 1

[0039] (1) Take 5 parts of hydrogenated polyisobutylene, 10 parts of N, N'-m-phenylene bismaleimide, 12 parts of polyvinyl chloride, and 40 parts of butyl rubber by weight, and add the above ingredients into the internal mixer , the temperature of the internal mixer is 100°C, and the mixing time is 10min;

[0040] (2) Then add 6 parts of KH570 silane coupling agent, 1.5 parts of N-phenyl-β-naphthylamine, 4 parts of magnesium hydroxide, 9 parts of nano-silicon carbide, 3 parts of nano-titanium nitride, bromine Melt 7 parts of bisphenol A type epoxy resin, keep the temperature constant, and then knead for 10 minutes;

[0041] (3) The mixed rubber material is then kneaded on an open mill at a temperature of 60°C. After kneading, the kneaded rubber is pressed into tablets, strips are cut, and cooled to obtain a composite nano-mine cable sheath material.

Embodiment 2

[0043] (1) Take 10 parts of hydrogenated polyisobutylene, 6 parts of N, N'-m-phenylene bismaleimide, 20 parts of polyvinyl chloride, and 25 parts of butyl rubber by weight, and add the above ingredients into the internal mixer , the temperature of the internal mixer is 80°C, and the mixing time is 20min;

[0044] (2) Then add 3 parts of KH570 silane coupling agent, 3.5 parts of N-phenyl-β-naphthylamine, 2 parts of magnesium hydroxide, 4 parts of nano-silicon carbide, 6 parts of nano-titanium nitride, bromine Melt 4 parts of bisphenol A type epoxy resin, keep the temperature constant, and then knead for 5 minutes;

[0045] (3) The mixed rubber material is then kneaded on an open mill at a temperature of 40°C. After kneading, the kneaded rubber is pressed into tablets, strips are opened, and cooled to obtain a composite nano-mine cable sheath material.

Embodiment 3

[0047] (1) Take 6 parts of hydrogenated polyisobutylene, 9 parts of N, N'-m-phenylene bismaleimide, 15 parts of polyvinyl chloride, and 28 parts of butyl rubber by weight, and add the above ingredients into the internal mixer , the temperature of the internal mixer is 100°C, and the mixing time is 10min;

[0048] (2) Then add 4 parts of KH570 silane coupling agent, 3 parts of N-phenyl-β-naphthylamine, 3 parts of magnesium hydroxide, 8 parts of nano-silicon carbide, 5 parts of nano-titanium nitride, bromine Melt 6 parts of bisphenol A type epoxy resin, keep the temperature constant, and then knead for 10 minutes;

[0049] (3) The mixed rubber material is then kneaded on an open mill at a temperature of 60°C. After kneading, the kneaded rubber is pressed into tablets, strips are cut, and cooled to obtain a composite nano-mine cable sheath material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com