High-temperature resistant mark coating

A technology of high temperature resistance and marking, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve problems such as the gap between high temperature resistance and flame resistance, the high temperature resistance is not very good, and it is easy to burn.

Inactive Publication Date: 2015-09-23

赵志海

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The high-temperature resistant coatings currently used in China are generally phenolic, modified epoxy coatings, silicone coatings, etc., which are not very good at high temperature resistance, and are easy to burn, which cannot meet the needs of actual production. Steelmaking, continuous casting, rolling steel, etc. are usually It is necessary to mark the surface of high-temperature steel parts to eliminate steel-mixing accidents, and high-temperature furnaces, engines and other equipment that have been working in high-temperature environments for a long time also need to be protected with high-temperature resistant coatings

At present, the high-temperature-resistant coatings used in China are generally modified epoxy coatings and silicone coatings, etc., and there is still a gap between their high-temperature resistance and flame resistance and actual needs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

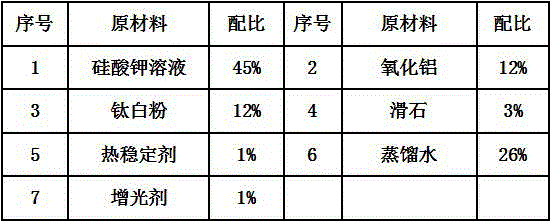

[0008] Mix all the raw materials in the formula, then ball mill for 80-100 hours in an enamel tank, and the fineness is not greater than 15 μm when measured with a lever micrometer, it is qualified.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

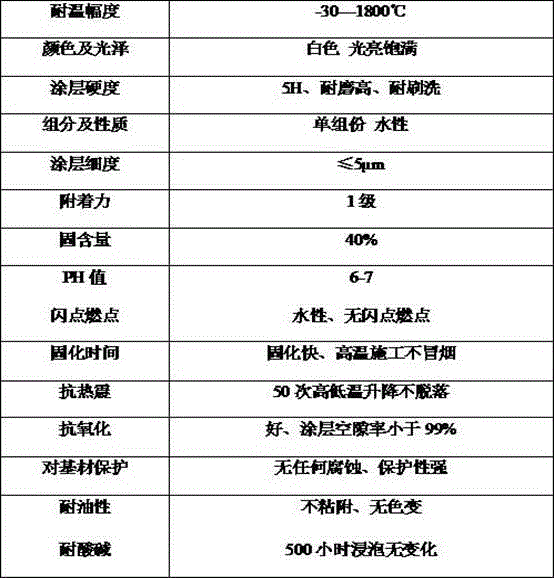

High-temperature resistant mark coating is made by heating inorganic solution with molecules modified and chelated, antiseptic pigment nanometal oxide, superfine rare earth micropowder, sensitizer and thermal stabilizer. The mark coating is resistant to 1800 degrees Centigrade, bright in color, fine and smooth, fast in curing time, long lasting and non-discoloring, acid and alkali resistance is iimproved, the advantages of inorganic texture are given into play completely, adhesion is good, and the mark coating can be coated with materials and is resistant to corrosion and oxidation at high temperature and normal temperature. The high-temperature resistant mark coating is used for marking metallurgy steel, high-temperature kilns, refractory materials, communication vehicles, space flight and aviation devices.

Description

technical field [0001] High temperature resistant marking paint is a water-based inorganic, high temperature resistant and corrosion resistant paint that can be painted on metal materials at room temperature and high temperature . Background technique [0002] High temperature resistant coatings generally refer to coatings used above 200 °C. The high-temperature resistant coatings currently used in China are generally phenolic, modified epoxy coatings, silicone coatings, etc., which are not very good at high temperature resistance, and are easy to burn, which cannot meet the needs of actual production. Steelmaking, continuous casting, rolling steel, etc. are usually It is necessary to mark the surface of high-temperature steel parts to eliminate steel-mixing accidents, and high-temperature furnaces, engines and other equipment that have been working in high-temperature environments for a long time also need to be protected with high-temperature resistant coatings. At prese...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D1/02C09D7/12

CPCB42D25/324

Inventor 赵志海

Owner 赵志海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com