Fuel engine with swash plate shaft

A fuel engine, swash plate shaft technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of low power output efficiency, large volume, heavy and other problems, and achieve the effect of high power output efficiency, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

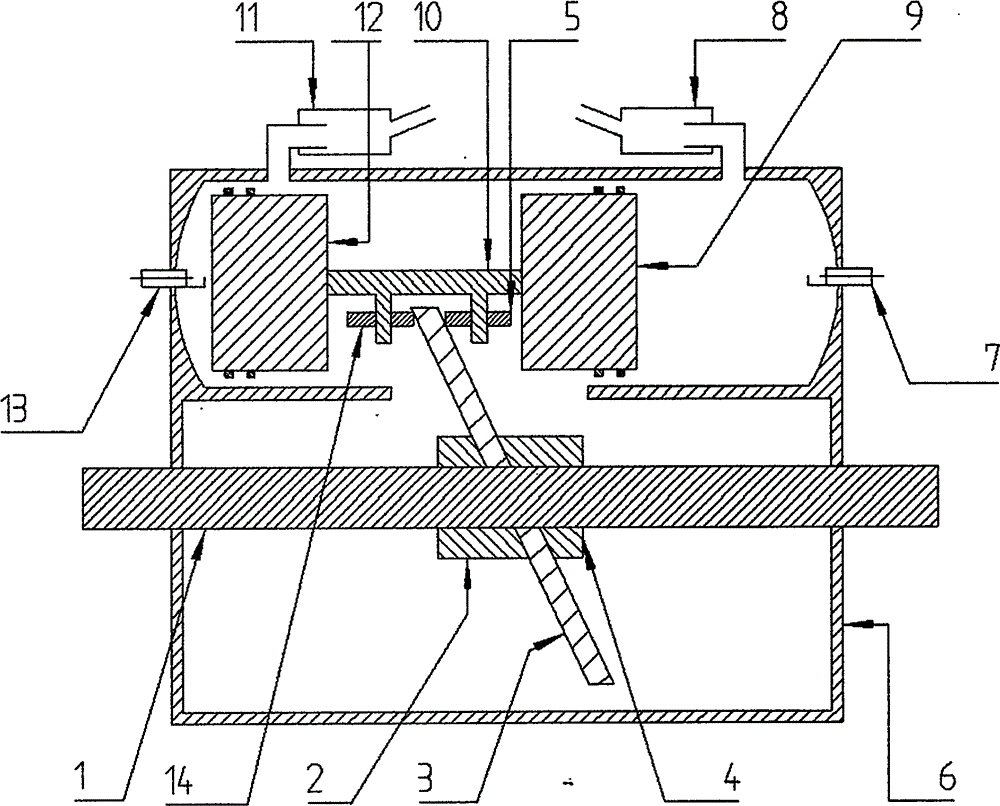

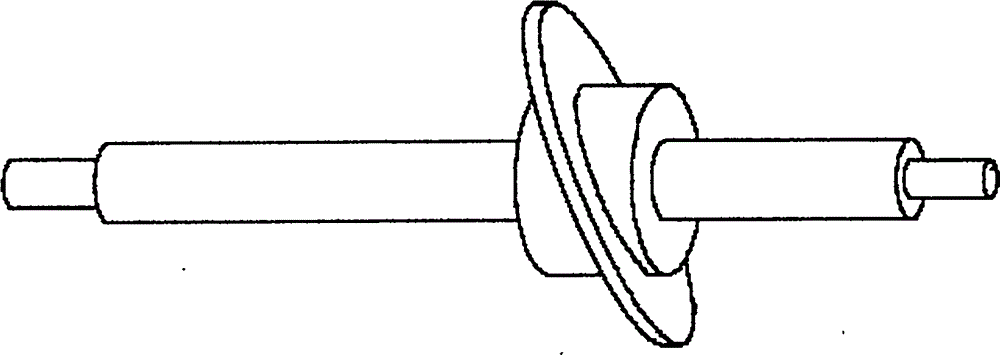

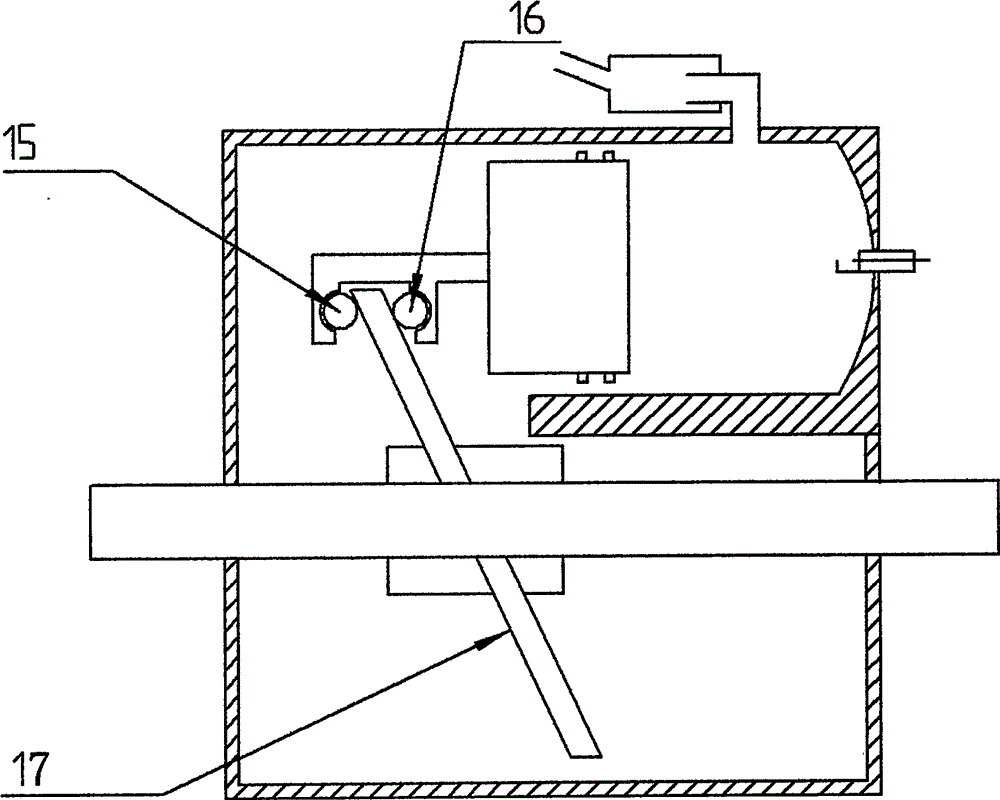

[0012] Such as figure 1 As shown, the swash plate reinforced clamp block 2, swash plate 3, and swash plate reinforced clamp block 4 are installed and fixed on the main shaft 1, and jointly constitute the swash plate shaft; The two combustion chambers are respectively equipped with spark plug 7 and spark plug 13; piston 9 and piston 12 are connected by connecting rod 10; connecting rod 10 is axially parallel to main shaft 1; bearing 5 and bearing 14 are installed on connecting rod 10; bearing 5 and A swash plate 3 is inserted in the middle of the bearing 14, and the swash plate 3 and the bearing keep a tight fit and can slide well.

[0013] The swash plate shaft fuel engine works in a two-stroke manner. When the swash plate shaft fuel engine works, the combustion chamber where the piston 9 is located and the combustion chamber where the piston 12 is located work alternately. When the combustion chamber where the piston 12 is located works, the spark plug 13 ignites, ignites th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com