Testing system of steam hydrophobic valve type

A test system and trap technology, applied in the field of trap test systems, can solve the problems of increasing the risk of affecting test safety, inconvenient test process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

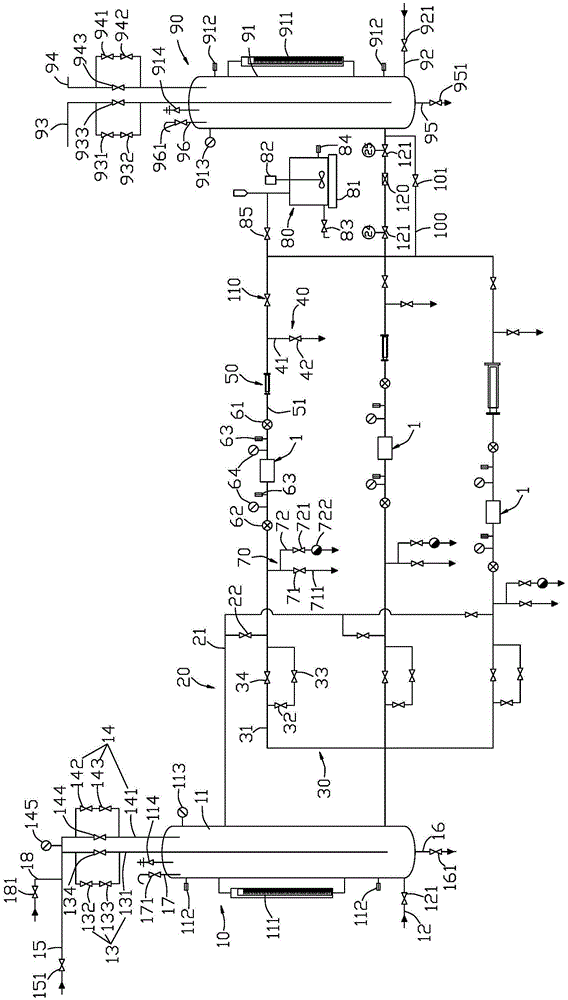

[0053] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0054] The steam trap type test device of the present invention is suitable for testing mechanical, thermostatic, and thermodynamic steam traps with a nominal diameter of DN80 and a nominal pressure of PN64 or below.

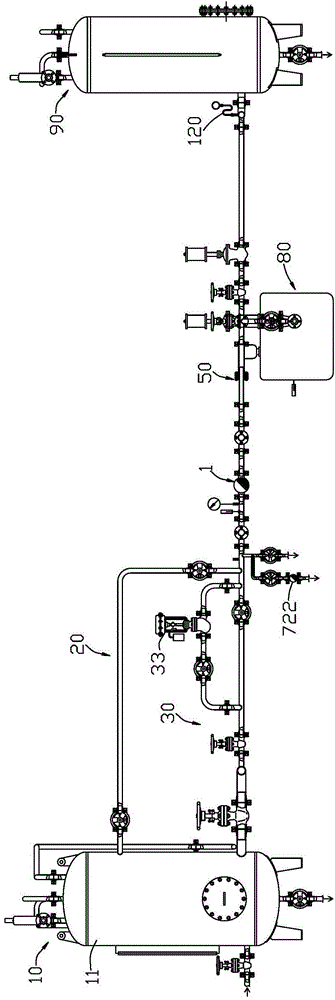

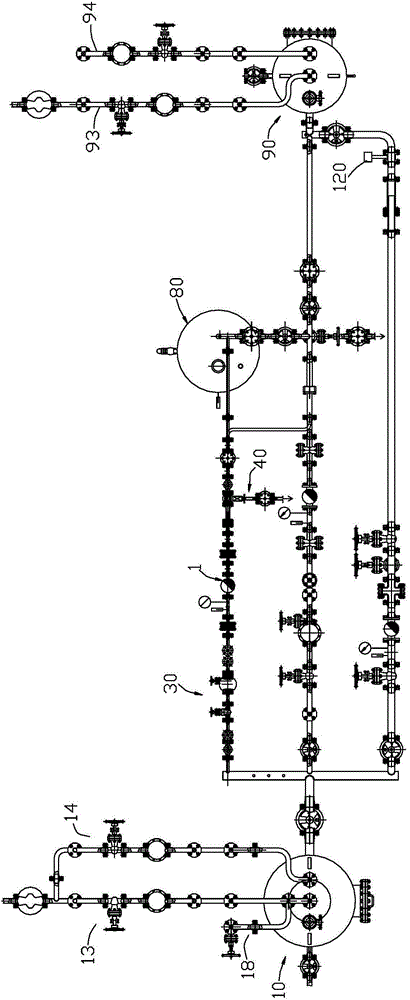

[0055] Such as Figure 1-3 As shown, the steam trap type test device according to an embodiment of the present invention includes a high-pressure tank device 10, a steam pipeline 20, a hot condensate pipeline 30, a discharge pipeline 40, a tubular expansion joint 50 and a monitoring device. The high-pressure tank device 10 provides steam and hot condensed water of prescribed test pressure and test temperature for the steam trap 1 to be tested (i.e. the steam trap to be tested); the steam line 20 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com