Test device for testing creep of metal materials under low stress

A metal material, creep test technology, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems that cannot meet the requirements of higher precision testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

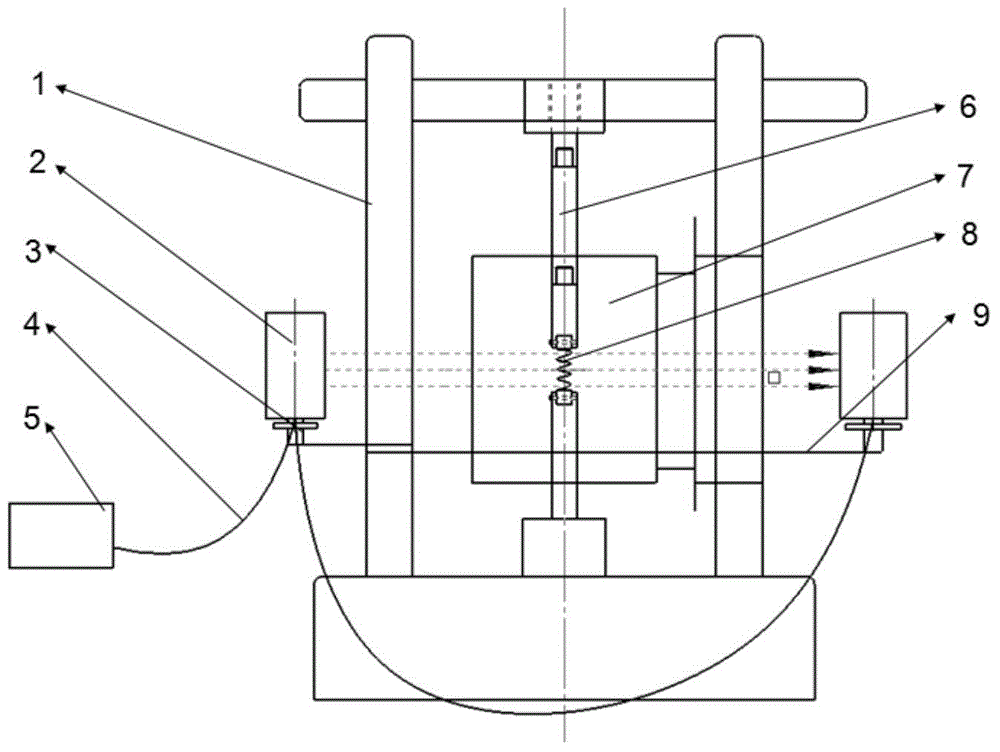

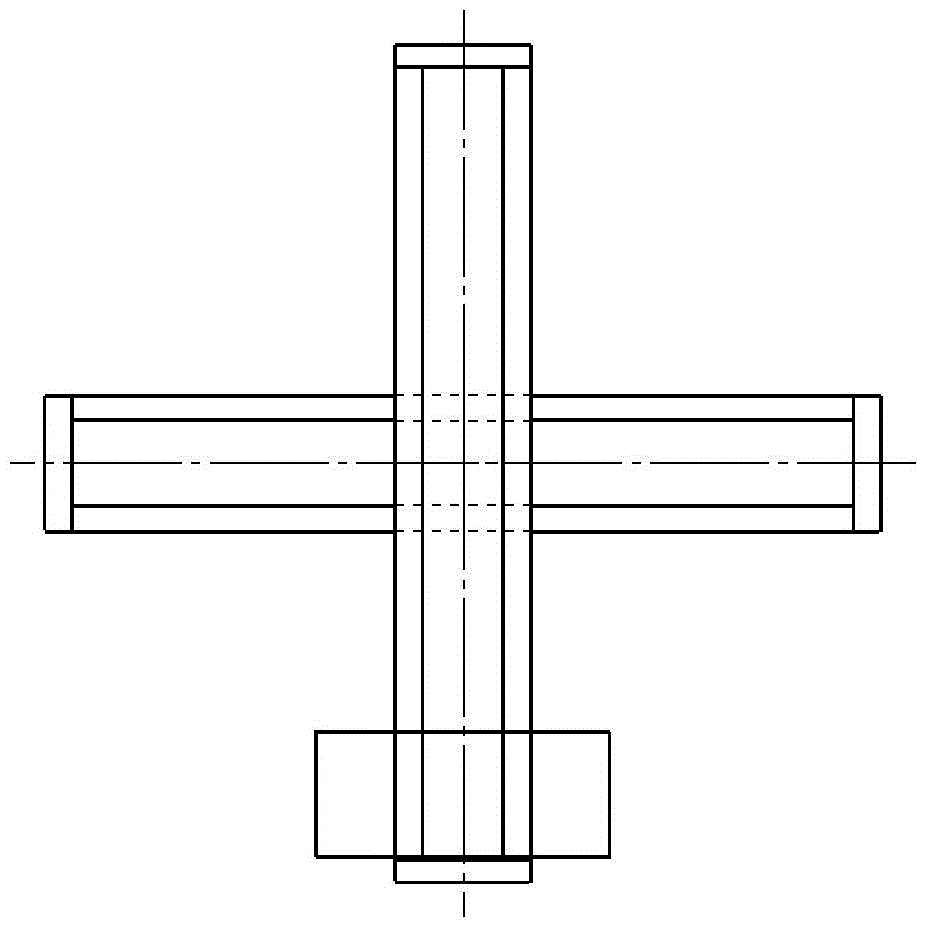

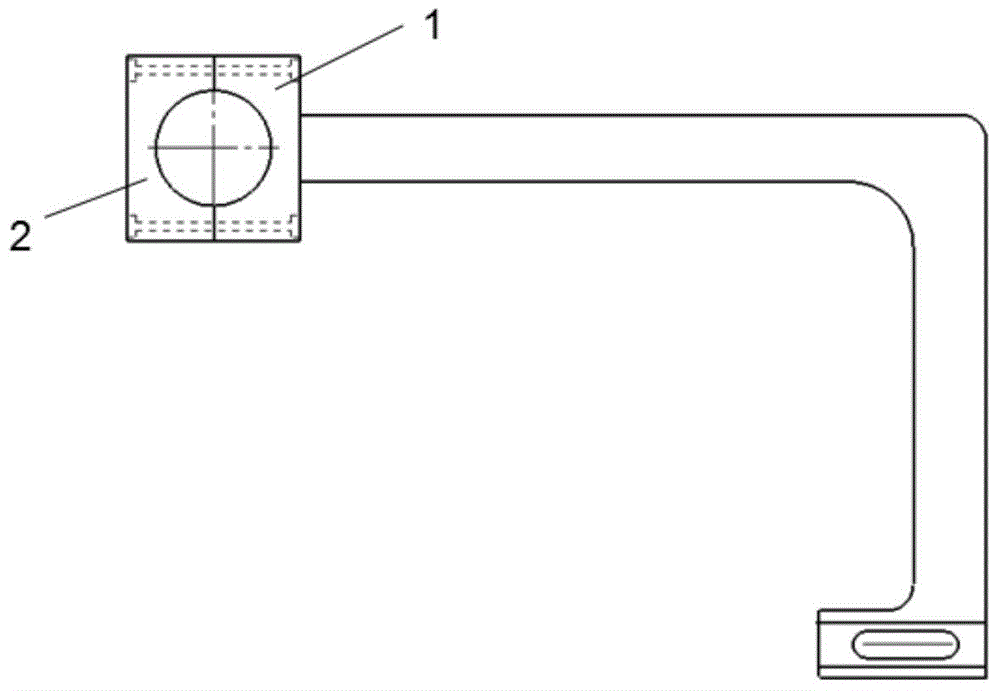

[0025] Such as figure 1 The creep test device for testing metal materials under low stress is shown, the device mainly includes: main frame 1, non-contact optical measurement system 2, sample fixture 6, window-type high-temperature furnace 7, spiral sample 8, fixed Frame components, computer 5, connecting wire 4, etc.; wherein, the main frame adopts a double-column portal frame structure, and the window-opening high-temperature furnace is fixedly installed on one side column of the main frame through a side mounting bracket. The spiral sample is installed on the sample fixture, and the sample fixture is installed at the center of the upper beam of the main frame, and ensures that the spiral sample is placed at the center of the window-type high-temperature furnace; the non-contact optical measurement system includes a receiver , Transmitter, display and connecting wires, the transmitter and receiver are respectively installed on the fixed frame assembly, the fixed frame assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com