Method for detecting quality of locomotive electric eddy current velocity sensing pulse generator

A technology of pulse generator and speed sensing, which is applied in the testing/calibration of speed/acceleration/shock measuring equipment, speed/acceleration/shock measurement, measuring devices, etc., which can solve the problem of high cost of testing and calibration and inconvenient test environment , long time period and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

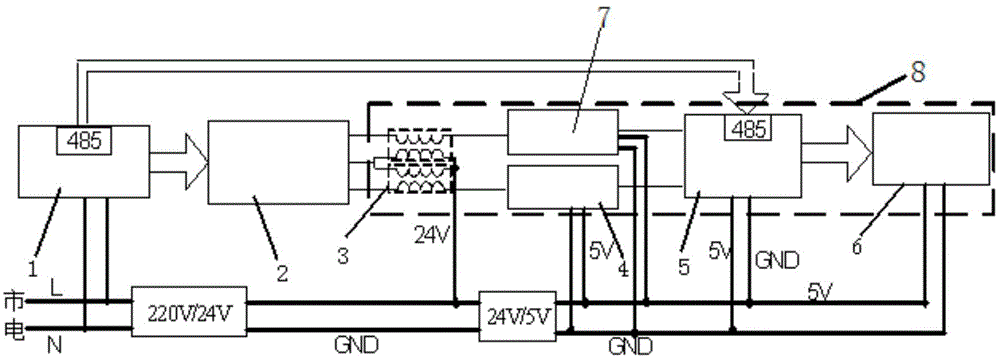

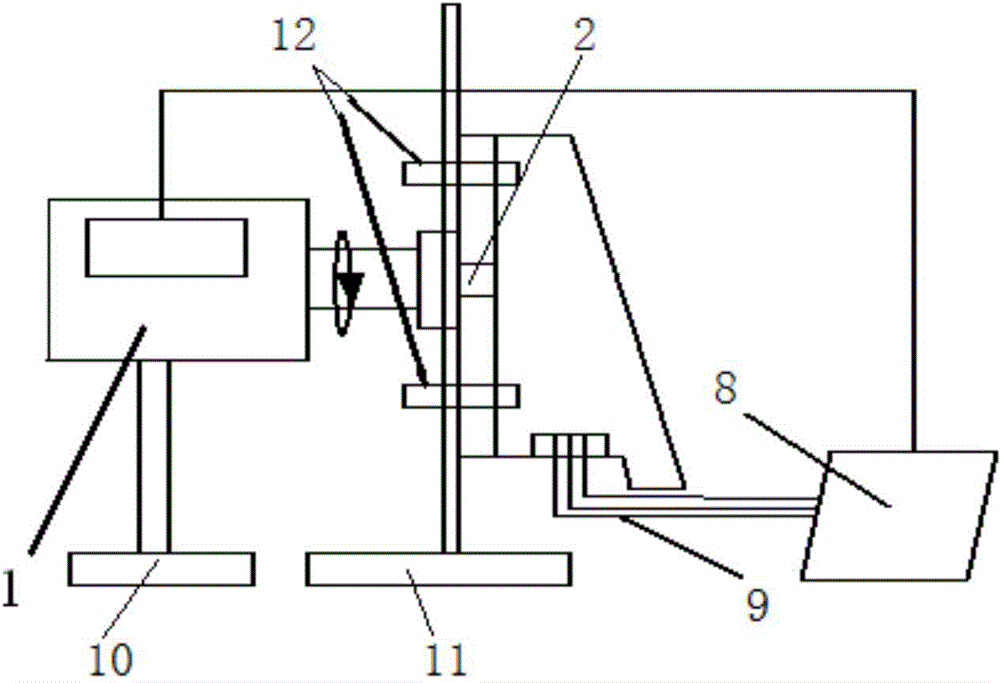

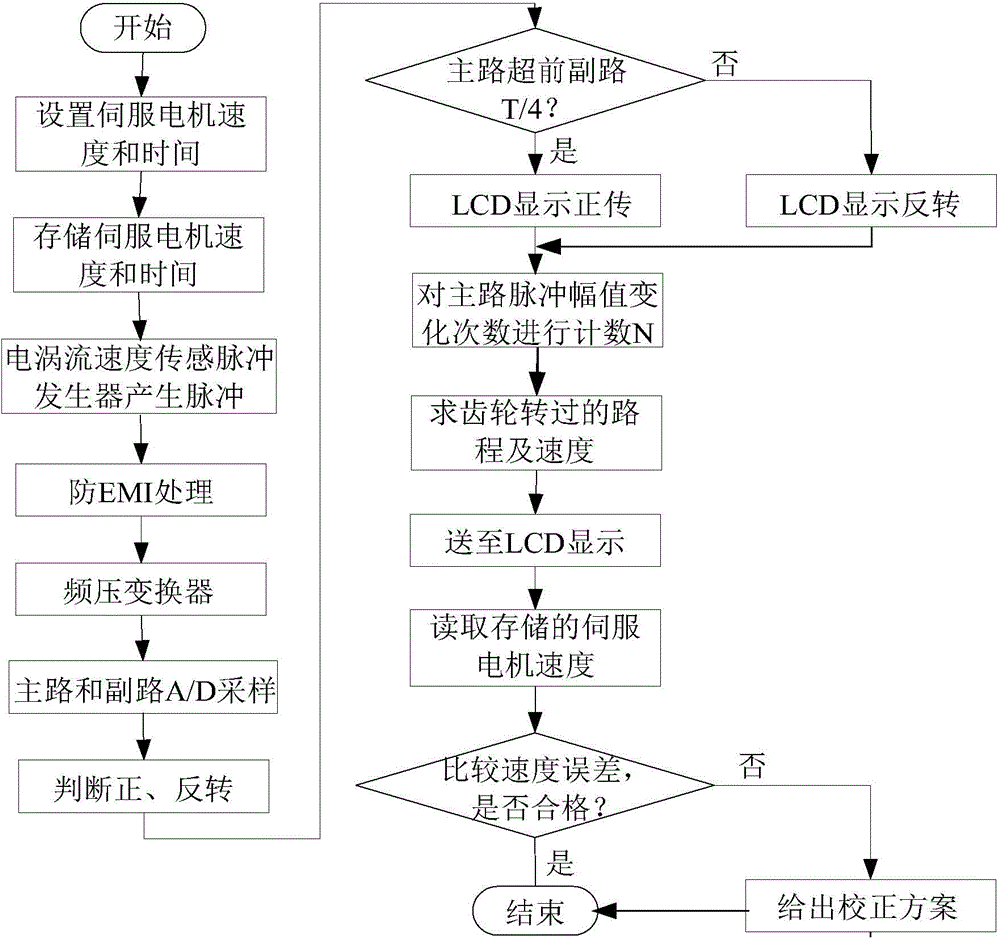

[0071] The present invention is a method for detecting the quality of a locomotive eddy current speed sensing pulse generator, which adopts a test system of an eddy current speed sensing pulse generator, such as figure 1 As shown, it includes a servo speed-regulating motor 1 and an eddy current speed sensing pulse generator 2 connected in sequence. The eddy current speed sensing pulse generator 2 outputs two signals, which are processed by the anti-EMI processing device 3 and then transmitted to the frequency-voltage conversion respectively. Among the frequency-voltage converter A4 and the frequency-voltage converter B7, the frequency-voltage converter A4 and the frequency-voltage converter B7 are connected to the input terminal of the microcontroller 5, and the output terminal of the microcontroller 5 is connected to the LED display 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com