Angle compensation kinematics solving method of one kind of rod end floating type six-freedom-degree parallel robots

An angle compensation and floating type technology, applied in the field of automation, can solve problems such as complex calculation process, real-time and accuracy need to be strengthened, and initial value selection requirements are not strict

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

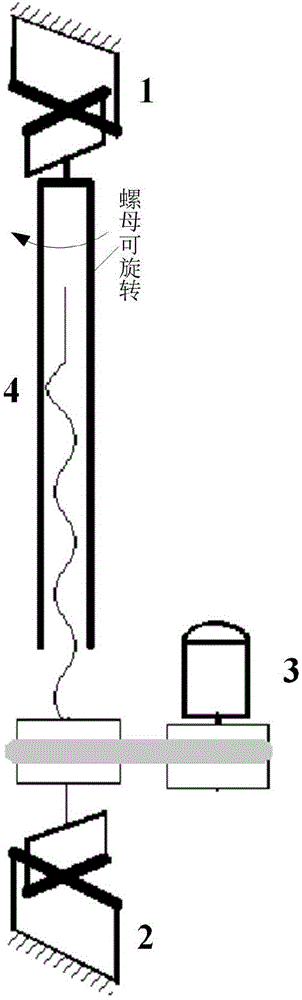

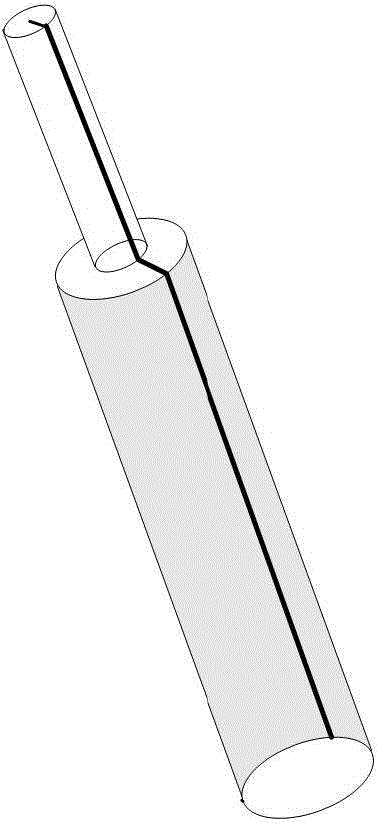

[0049] see figure 1 As shown, the rod-end floating six-degree-of-freedom parallel robot involved in the present invention includes a fixed platform and a moving platform, six fixed platform Hooke joints 2 are installed on the fixed platform, and six moving platform tiger joints are installed on the moving platform. Hooke hinge joint 1; fixed platform Hooke hinge joint 2 and corresponding moving platform Hooke hinge joint 1 are connected through rod end floating ball screw pair 4; rod end floating ball screw pair 4 are all driven by motor 3.

[0050] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

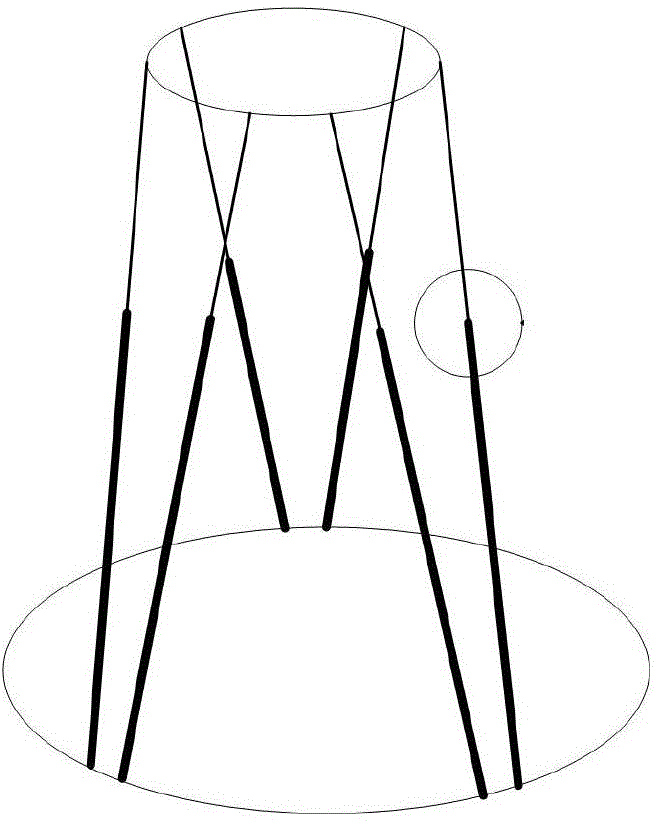

[0051] First, specify the way to establish the coordinate system, such as image 3 shown, where:

[0052] Fixed platform coordinate system O b -x b the y b z b — Order B i , i=1,2,...6 represent the center points of the six Hooke joints installed on the fixed platform, by B i The geometric cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com