Calf milk feeding vehicle

A calf and milk tank technology, which is applied in the field of livestock breeding, can solve the problems of low feeding efficiency, inability to walk on its own, small milk storage capacity, etc., and meet the requirements of convenient and rapid feeding process, improved controllability, and physical fitness Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

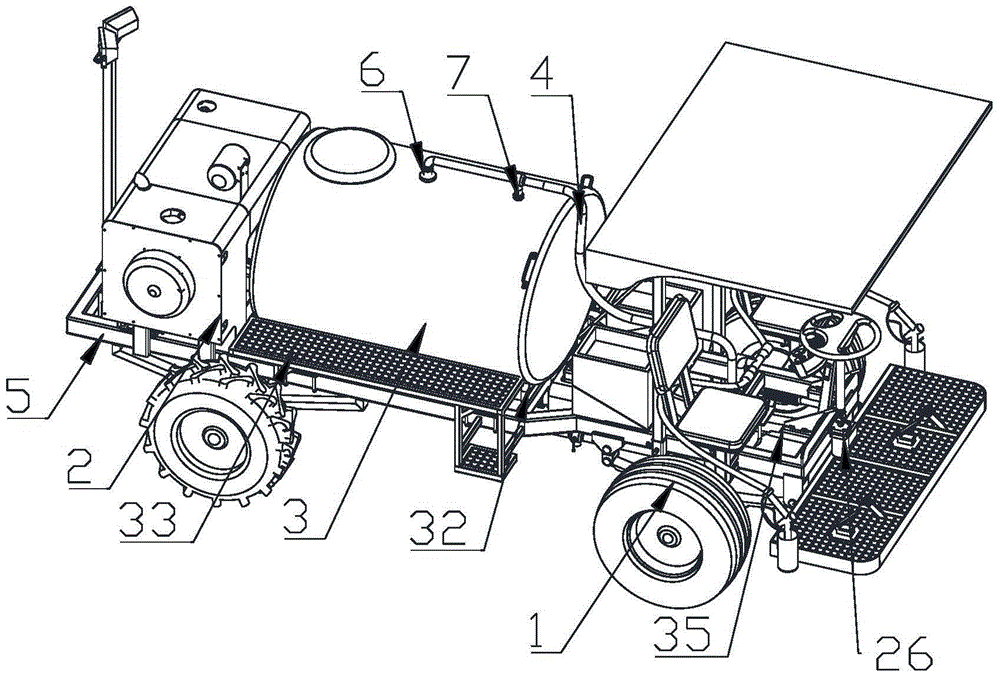

[0014] A calf-feeding vehicle, which includes a carrier vehicle 1, a hydraulic drive system 2, a milk tank 3 and a milk feeding pipeline 4, wherein the front part of the carrier vehicle 1 is an operating area 35, and the rear part is provided with a fixed beam frame 5, and the hydraulic drive system 2. The milk tank 3 and the feeding pipeline 4 are fixed on the beam frame 5. The carrier vehicle 1 is used to transport milk. The operating area 35 is provided with a roof, a seat, an instrument panel, etc., so that the operator can control the vehicle body.

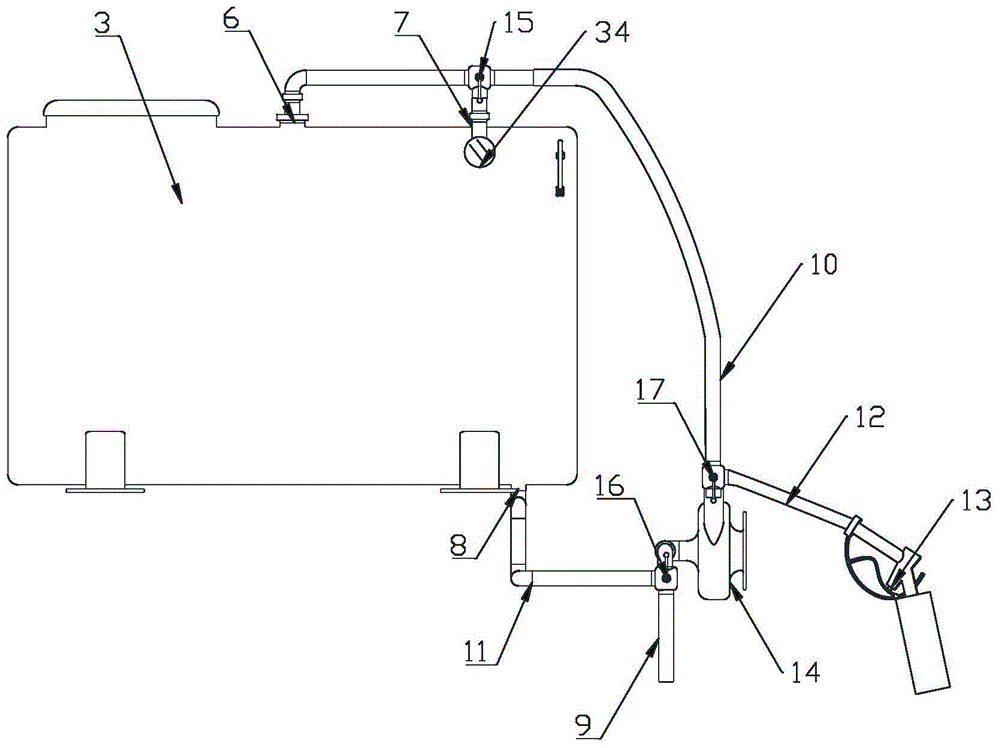

[0015] The upper part of the milk tank 3 is provided with a milk inlet 6 and a cleaning port 7, the lower part of the milk tank 3 is provided with a milk outlet 8, and the feeding pipeline 4 includes a milk inlet pipe 9, a tank inlet pipe 10, a tank outlet pipe 11, and a milk outlet pipe 12 1. The milk gun 13 and the sanitary pump 14 are connected with a cleaning three-way valve 15 on the cleaning port 7, and the other two por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com