Environment-friendly fume-suction weld cap

A welding cap and environmental protection technology, applied in the field of welding auxiliary tools, can solve the problems of high energy consumption and large investment, and achieve the effects of short distance, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

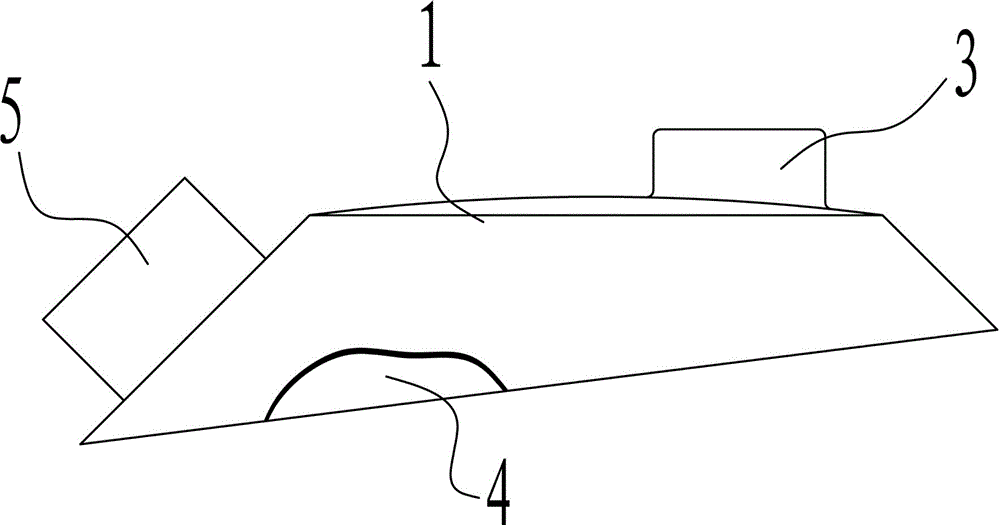

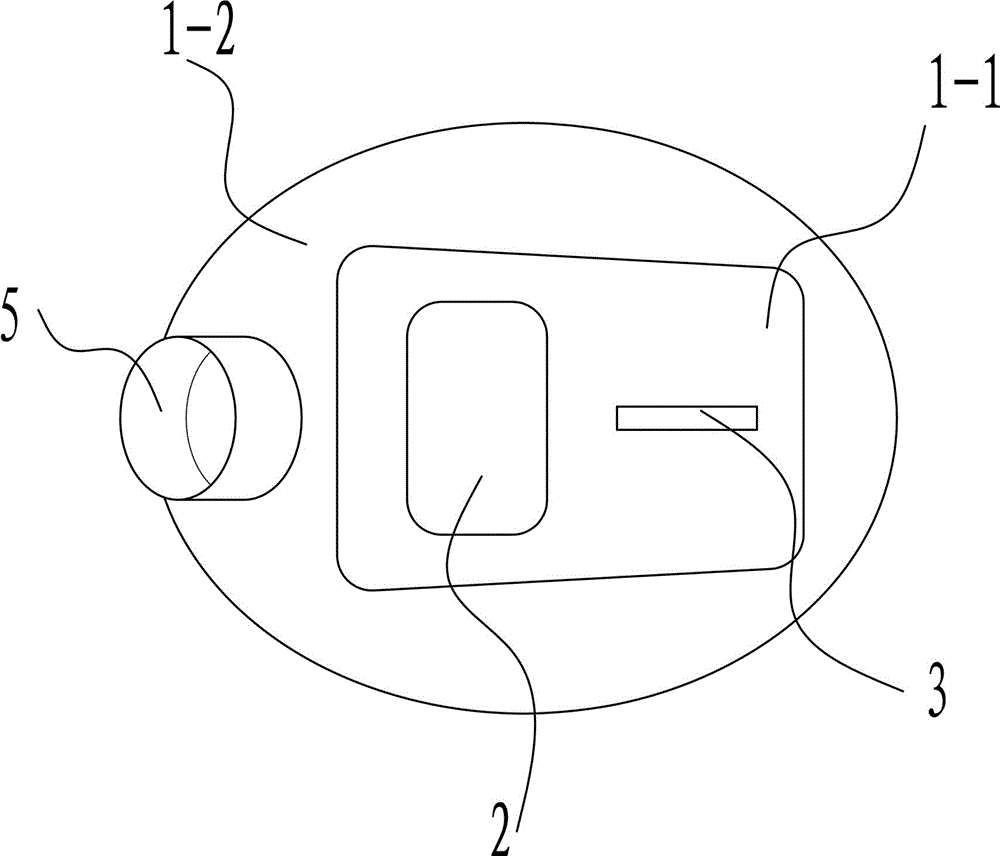

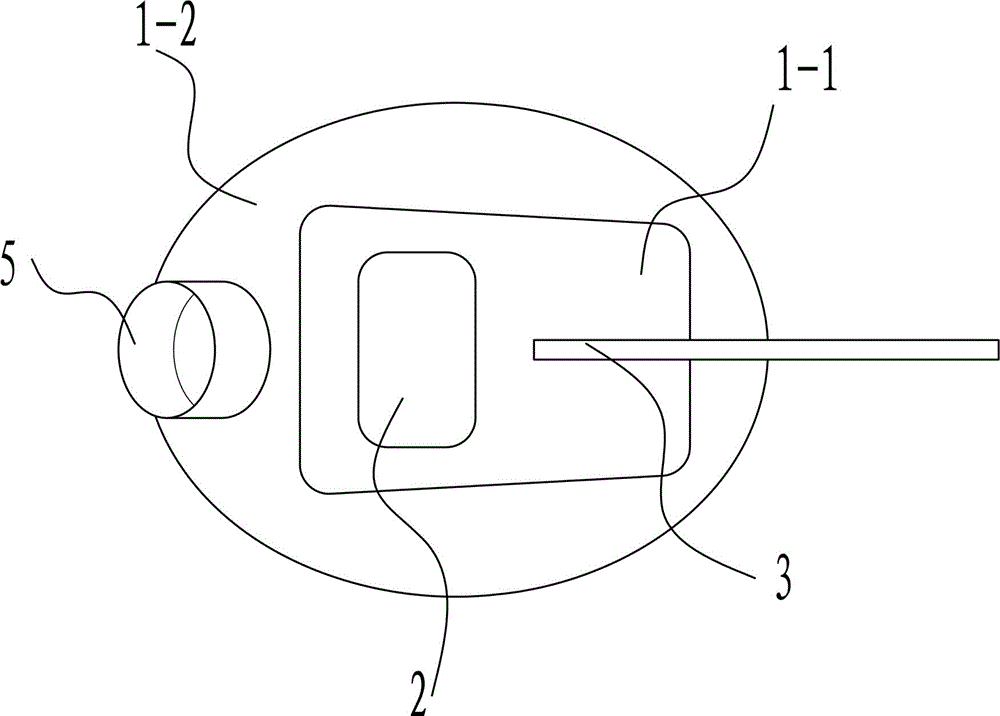

[0020] The following is attached Figure 1-3 The present invention is further described in detail.

[0021] as attached figure 1 and 2 As shown, an environmentally friendly smoking welding helmet mainly includes a cover body 1, and the cover body 1 includes a bottom plate 1-1 and a cover wall 1-2 arranged around the bottom plate 1-1, and the cover wall 1-2 Set on the side of the bottom plate 1-1 facing the working surface, the cover wall 1-2 and the bottom plate 1-1 form a smoke accumulation area 4 for storing smoke and dust on the working surface, and the smoke accumulation area 4 The area of the opening end is larger than the area of the bottom plate 1-1, and is used to accommodate the fume generated during welding. The bottom plate 1-1 is provided with a sight glass installation window, and a sight glass 2 is installed in the sight glass installation window, so as to facilitate workers to observe the welding situation through the sight glass. A handle 3 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com