Novel special superfine dispersion system for lithium battery electrode slurry

A technology of electrode slurry and dispersing system, applied in the field of dispersing machines, can solve the problems of low dispersing efficiency, uneven dispersing, skinning, etc., and achieve the effects of high dispersing efficiency, short residence time and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

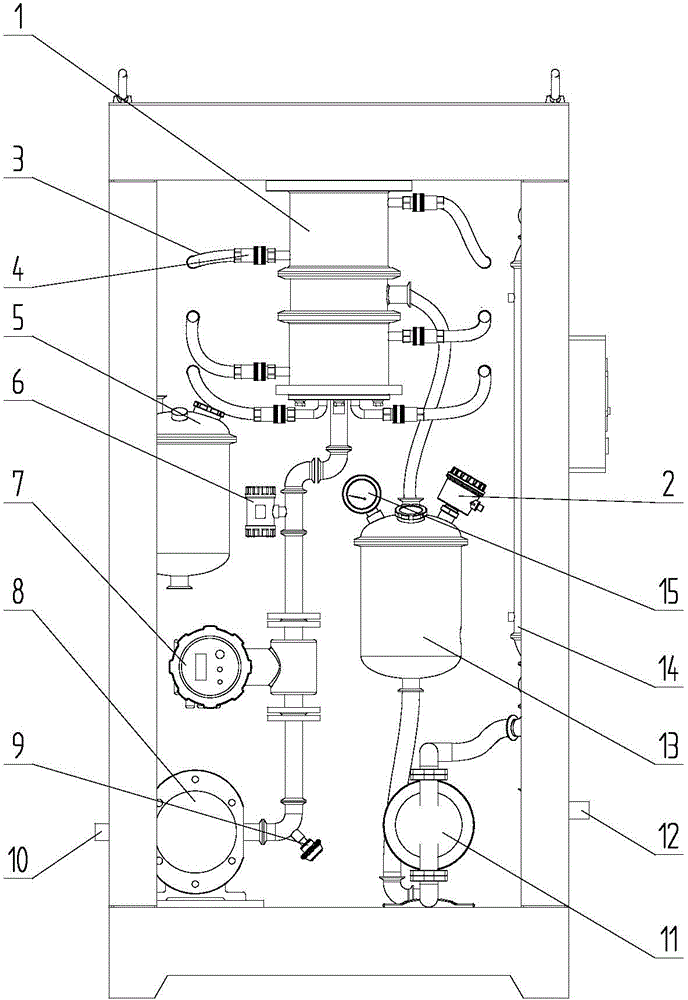

[0017] Such as figure 1 As shown, the special ultrafine dispersion system for the novel lithium battery electrode slurry in this embodiment includes a frame in which a main engine 1, a rotor pump 8, a vacuum buffer tank 5, a discharge buffer tank 13 and a diaphragm pump 11 are installed. The rotor pump 8 is connected to the feed port 10 on one side of the frame. The connecting pipe between the main engine 1 and the rotor pump 8 is equipped with a flowmeter 7, a pressure sensor 6 and a thermometer 9. One side of the main engine 1 is connected to the cooling water pipe through the water pipe joint 4. 3. The main engine 1 is connected to the discharge buffer tank 13, the liquid level gauge 2 and the pressure gauge 14 are installed on the discharge buffer tank 13, the discharge buffer tank 13 is connected to the diaphragm pump 11, and the diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com