Tube bender for bending tubing

A pipe bending machine and oil pipe technology, which is applied in the field of auto parts production equipment, can solve the problems of difficult bending angle and strength, multiple bending angles, and uneven height of bending places, etc., to achieve precise control of bending The angle and strength of folding, high pass rate, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the drawings and specific embodiments.

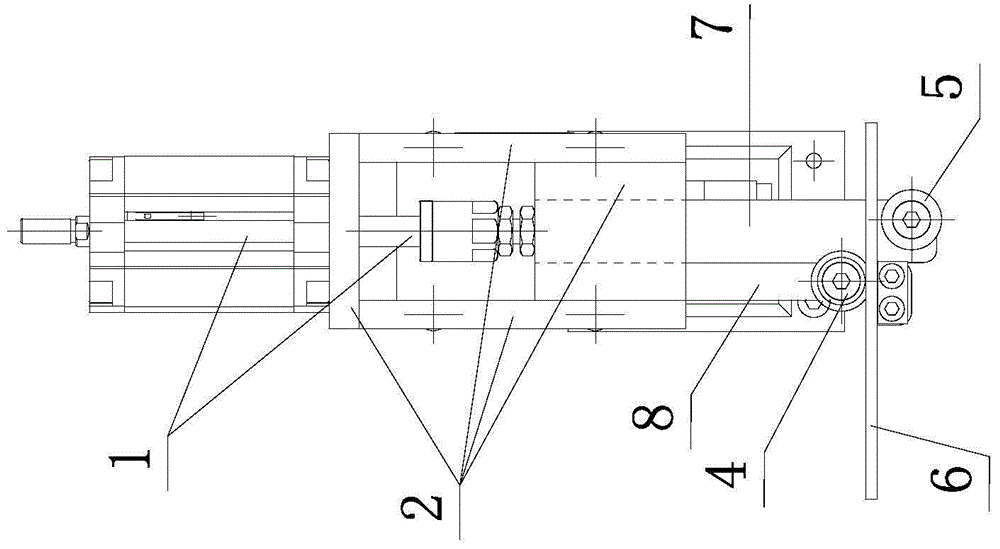

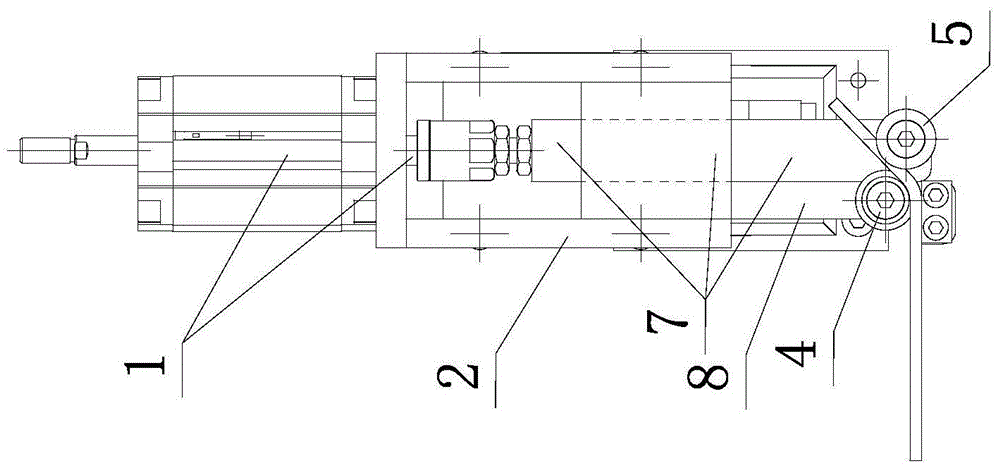

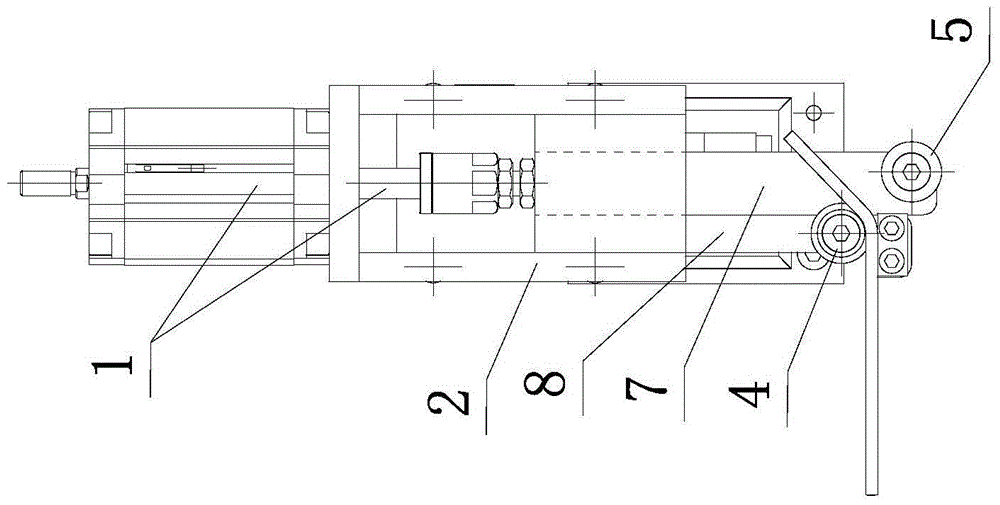

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6, Figure 7, Figure 8, Figure 9, Figure 10, Picture 11 , Picture 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 As shown, the pipe bender used for bending the oil pipe of the present invention includes a stretch bending module, a top bending module, a twisting module and a base 22. A pneumatic clamp, such as SMC pneumatic finger 43, is installed on the base 22 to clamp the oil pipe 6 that needs to be bent.

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, each stretch-bending module includes a stretch-retracting driving cylinder 1 and a first fixing frame 2. The first fixing frame 2 of each stretch-bending module is mounted on the base 22 via an adjustable support 3. Specifically, the adjustable suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com