Highly-transparent optical polyester film and preparation method thereof

A technology of optical polyester film and optical polyester, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problem of increased fogging degree of polyester film, poor compatibility of polyester, polyester film Transparency damage and other problems, to improve processing performance, improve light transmittance and gloss, overcome the effect of fogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

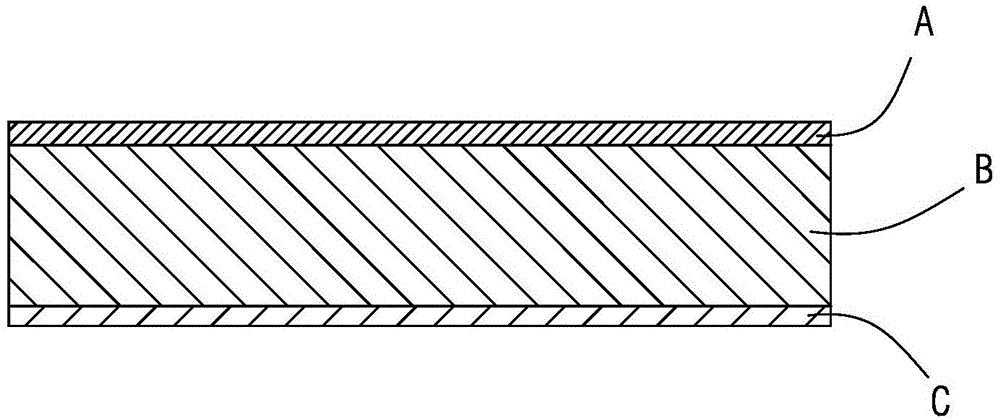

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0040] As mentioned above, the present invention provides a kind of high-transparency optical polyester film and its preparation method, to solve the self-adhesive and easy-to-scratch problems that are easy to occur when the high-transparency optical polyester film is rolled, improve the processing performance of the film, and at the same time Overcome the fogging phenomenon of the film and improve the light transmittance and gloss of the film. Through the improved material components and optimized preparation method of the present invention, the prepared high-transparency optical polyester film has excellent optical properties, and is especially suitable for protective films and reflective films in flat panel display screens that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com