Automatic end sealing device for large-scale coil stock peripheral coating film

A roll material and end-sealing technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of certain size and shape requirements, low degree of automation, and low packaging qualification rate, so as to optimize the structure and work flow , easy layout, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

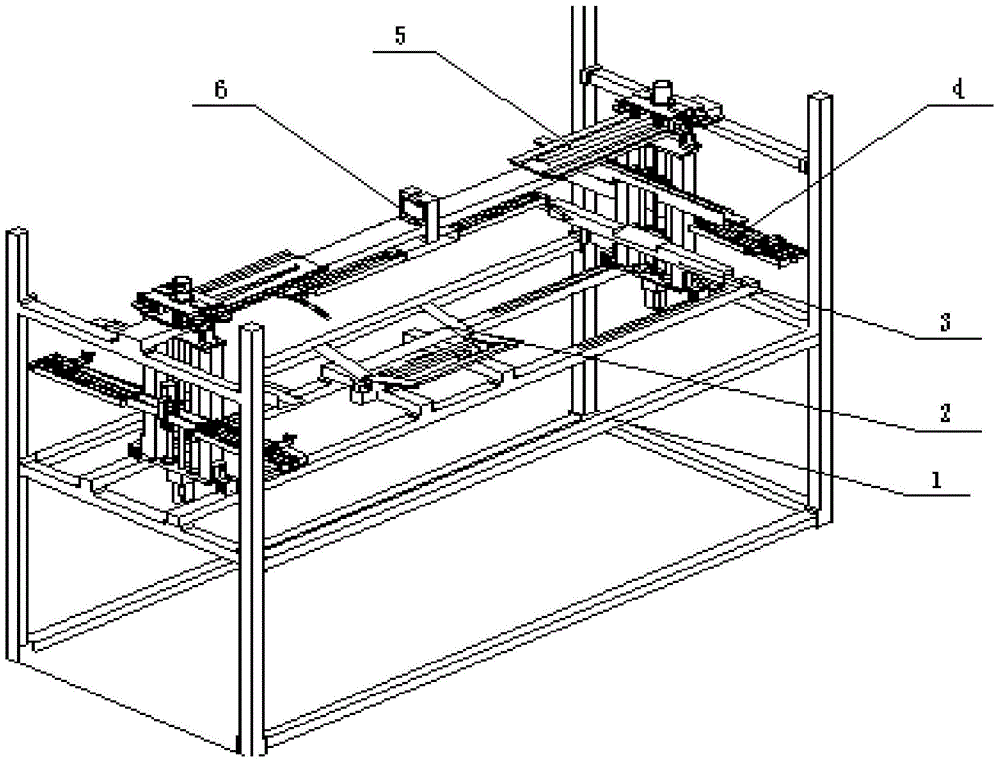

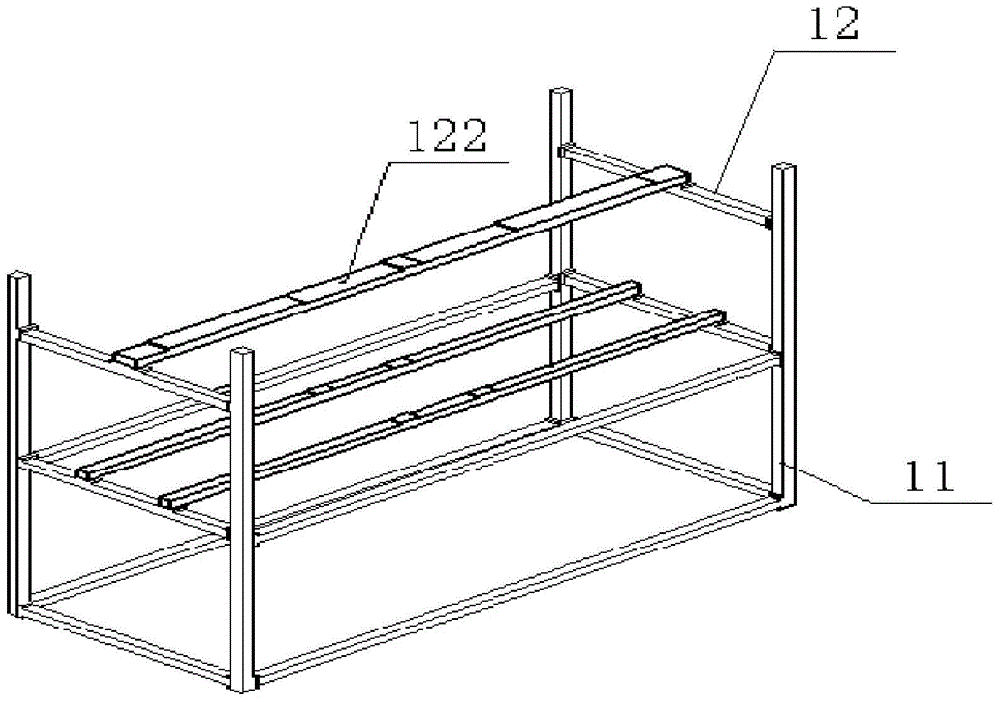

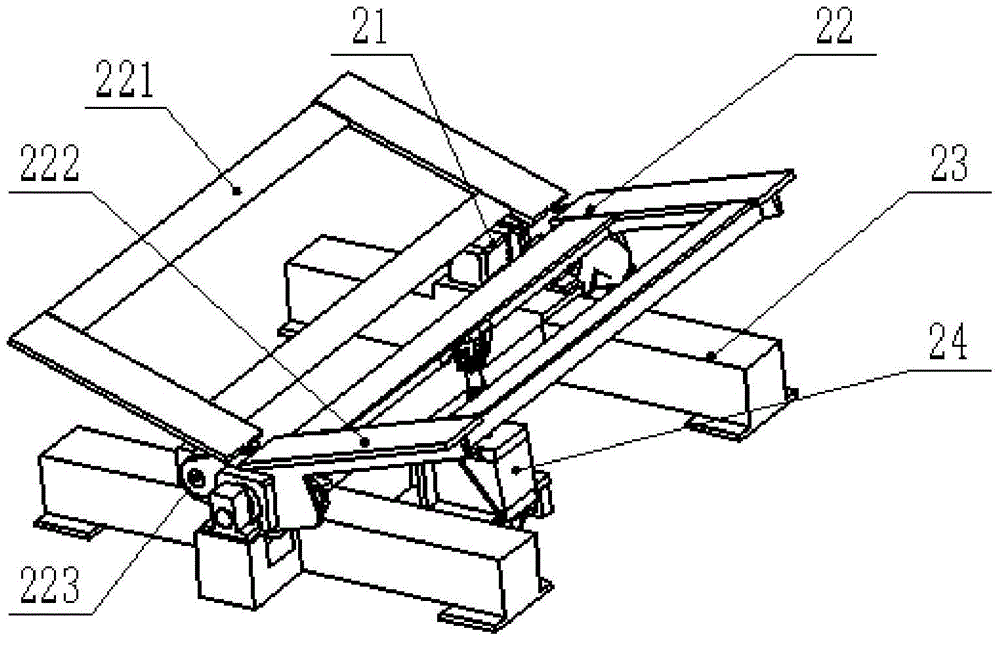

[0032] The automatic end-sealing device for the circumferential film coating of large coils provided by the present invention includes an end-seal frame 1 and a coil positioning and conveying device 2 installed on the end-seal frame, a heat-sealing device 3, a film support device 4, and a horizontal feed Device 5, negative pressure film suction device 6; the end sealing frame is divided into a stand and a mounting frame, the top of the frame 11 is open, and the mounting frame 12 includes a horizontal beam 122 positioned above the top of the frame, The space between the mounting frame and the platform can accommodate the rolling of the coil material that has completed the circumferential film coating, and the direction of the horizontal beam is parallel to the axis direction of the coil material;

[0033] The mounting frame 12 is positioned at two opposite sides of the frame and above the frame, and the space between the mounting frame and the frame can accommodate the roll mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com