Fire-proof core veneer material for elevator door, fire-proof core veneer and production method of fire-proof core veneer

A production method and fireproof core technology, which is applied in the field of fireproof core board and its production, and fireproof core board materials for elevator doors, which can solve the problems of poor fire resistance and failure to reach A1 level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

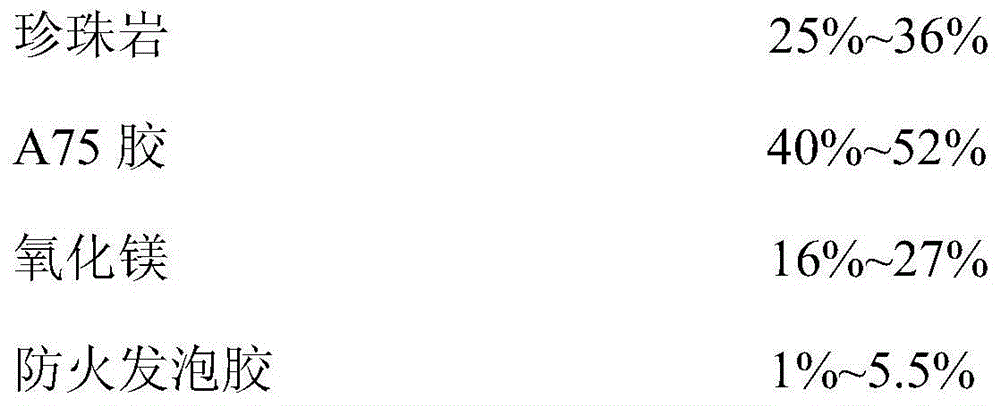

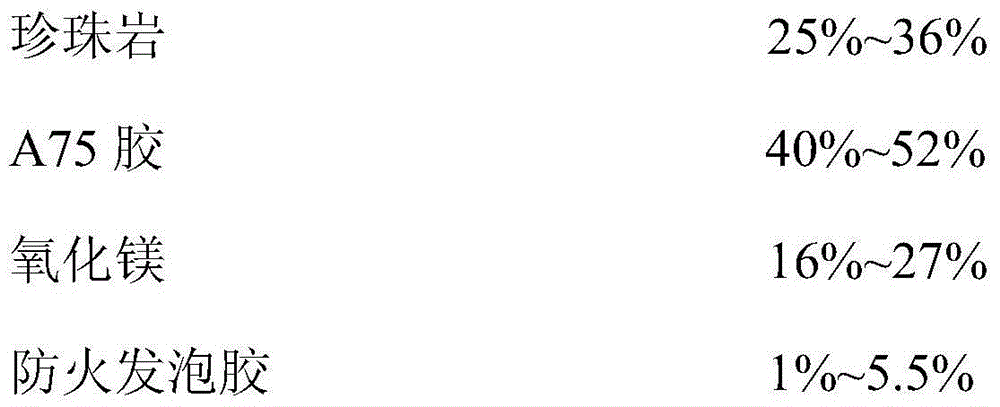

[0038] A, take perlite 30.3%, magnesia 21.1%, fireproof styrofoam 3.2%, A75 glue 45.4% by weight percentage, and get the elevator door panel ready;

[0039] B. Stirring the mixture: at room temperature, add perlite, magnesium oxide, and fireproof foam glue to A75 glue, and stir evenly to obtain a fireproof mixture;

[0040] C. Filling material: Pour the fireproof mixture into the elevator door panel, heat and press for 30 minutes, the temperature is controlled at about 80°C, and the pressure is 8 tons;

[0041] D. Natural curing: After heating and pressing, the fire-resistant mixture is formed into a fire-resistant core board, and then the formed fire-resistant core board is left to stand for three days under natural ventilation to obtain a fire-resistant core board product;

[0042] E. Protection measures: After the elevator door panel is filled with fireproof core board products, the surface of the fireproof core board is covered with a 0.5mm thick steel plate, and then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com