Beer production technique and device for improving liquor body aroma

A production process and aroma technology, applied in biochemical equipment and methods, beer brewing, wort preparation, etc., can solve the problems of poor beer taste, high equipment utilization rate, and many by-products, so as to avoid volatilization, The effect of enhancing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

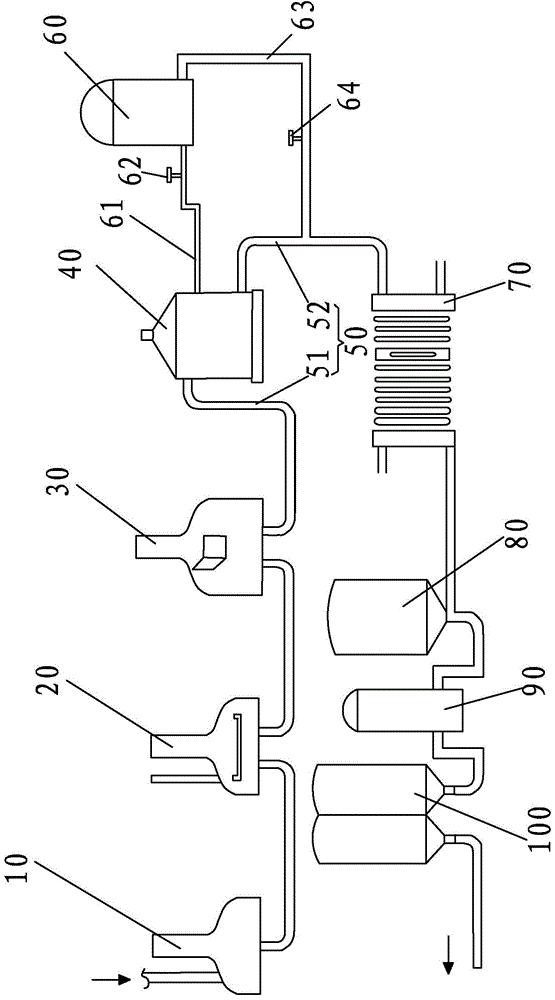

[0027] Such as figure 1 As shown, the present invention proposes a kind of beer production equipment for improving the aroma of the wine body, comprising a mashing pot 10, a lauter tank 20, a boiling pot 30, a cooler 70, a fermenter 80, a filter 90 and a sake tank 100 connected in sequence, The discharge end of the boiling pot 30 communicates with the feed end of the cooler 70 through the delivery pipeline 50, and also includes an addition tank 60, the discharge end of the addition tank 60 communicates with the delivery pipeline 50, and the hops are placed in the addition tank 60.

[0028] As a preferred mode of the present invention, it also includes a vortex sink 40, and the delivery pipeline 50 includes a first delivery pipeline 51 and a second delivery pipeline 52, and the feed end of the first delivery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com