Anti-static yarn-dyed damask fabric and manufacturing method thereof

An anti-static and twill fabric technology, which is applied in fabrics and its manufacture, yarn-dyed twill fabrics and its manufacture, can solve the problems of not having anti-static function, potential safety hazards of electric shock, inability to conduct electrostatic charge in time, etc., to achieve a wide range of applications, Reduce safety hazards, good anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

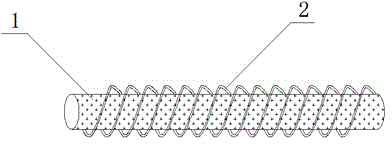

[0024] see figure 1 , a kind of antistatic yarn-dyed twill fabric fabric of the present invention, comprises central cotton fiber 1, is characterized in that: described central cotton fiber 1 is used as warp yarn, and the outer surface of central cotton fiber 1 is entangled and coated with conductive fiber 2, conductive The fiber 2 is used as the weft yarn, the central cotton fiber 1 is made of pure cotton filament, and the mass percentage of the central cotton fiber 1 in the composite yarn is 75%-85%, and the composite yarn is densely interwoven to form an antistatic fabric.

[0025] The fineness of the central cotton fiber 1 is 45dtex-146dtex, and the strength is 6cN / dtex-7cN / dtex.

[0026] The conductive fibers 2 are striped, and the distance between adjacent conductive fibers 2 is 2.5mm-4.8mm.

[0027] The conductive fiber 2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com