Heavy-load beam creel of double-needle-bar warp knitting machine

A double-needle bed warp knitting machine and heavy-duty technology, which is applied in the field of warp knitting machines, can solve problems such as insufficient load, and achieve the effects of increasing load, reducing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

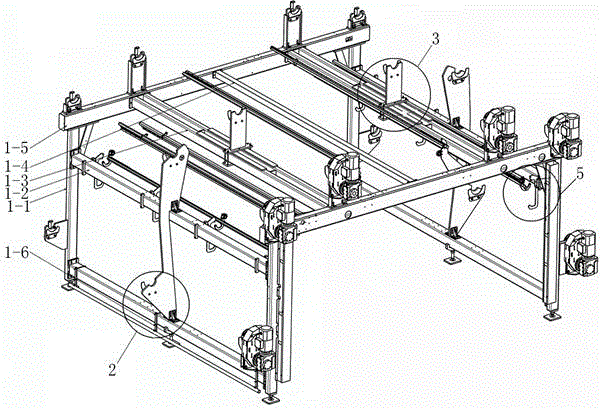

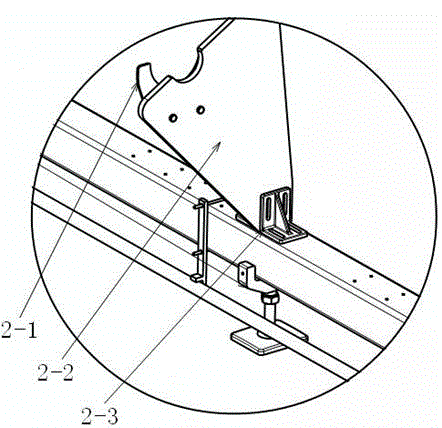

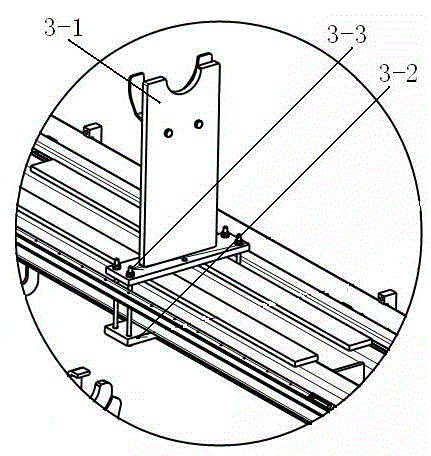

[0020] Such as Figure 1-6 It is a schematic diagram of the structure of the present invention, a heavy-duty warp beam support design for a double-needle bed warp knitting machine, including a warp beam frame 1, a warp beam middle support assembly 2, a warp beam seat 3, a segmented warp beam assembly 4, and a split yarn Rod assembly 5, upper yarn assembly 6, warp beam frame 1 includes four support column assemblies 1-1, four thick transverse support tubes 1-2, two double transverse support tubes 1-3, and one thin transverse support tube 1 -4. Two cross beam assemblies 1-5, middle support angle iron 1-6, the upper ends of the two support column assemblies 1-1 separated by a long distance are connected by cross beam assemblies, and double cross brace pipes are arranged between the cross beam assemblies 1- 3 and the thin cross brace tube 1-4, the thick cross brace tube 1-2 is set between the two support column assemblies 1-1 with a short distance apart, and the middle support angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com